Jig dyeing machine

A technology of jiggers and racks, which is applied in the field of jiggers, and can solve problems such as fabric breakage, cloth congestion, and excessive tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

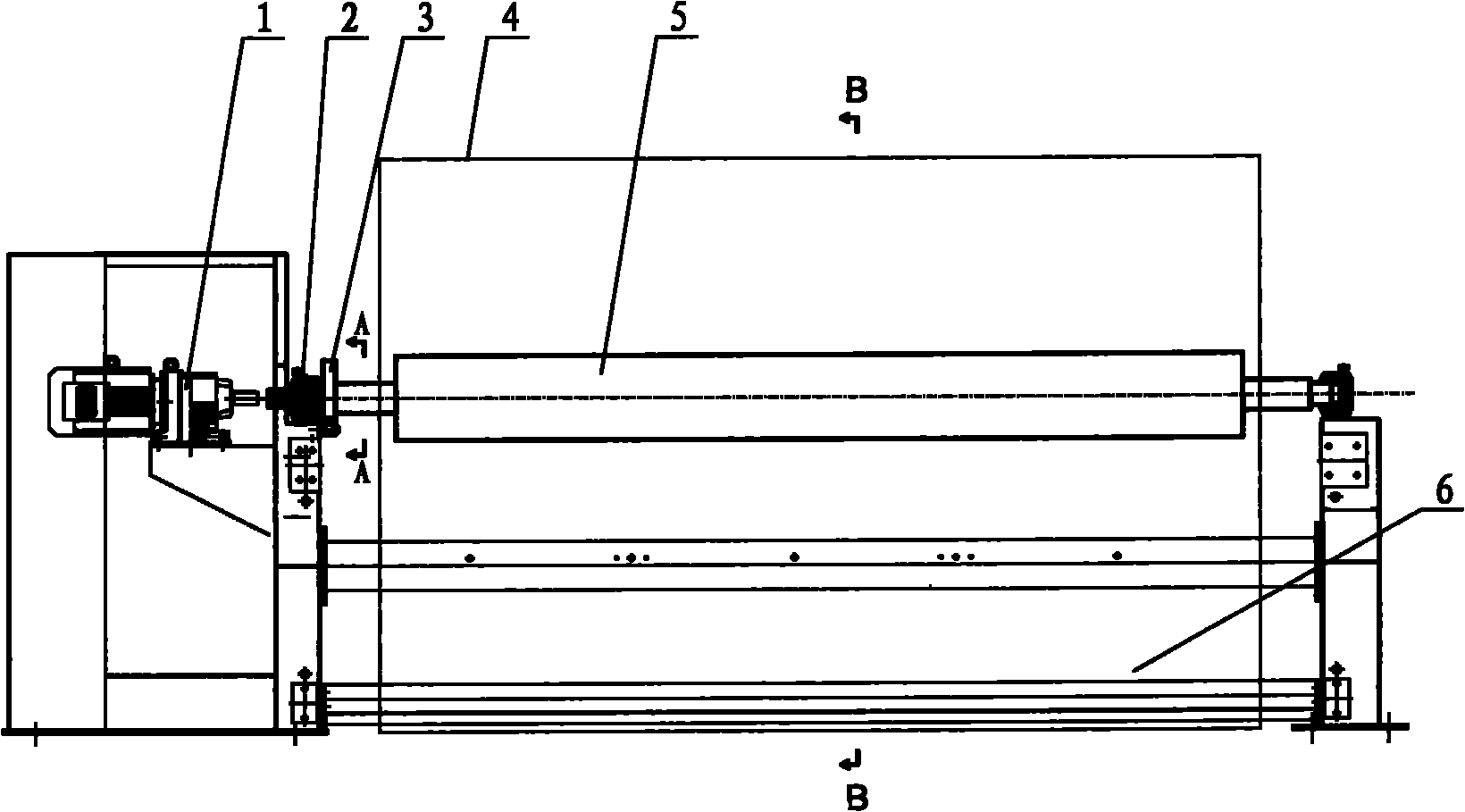

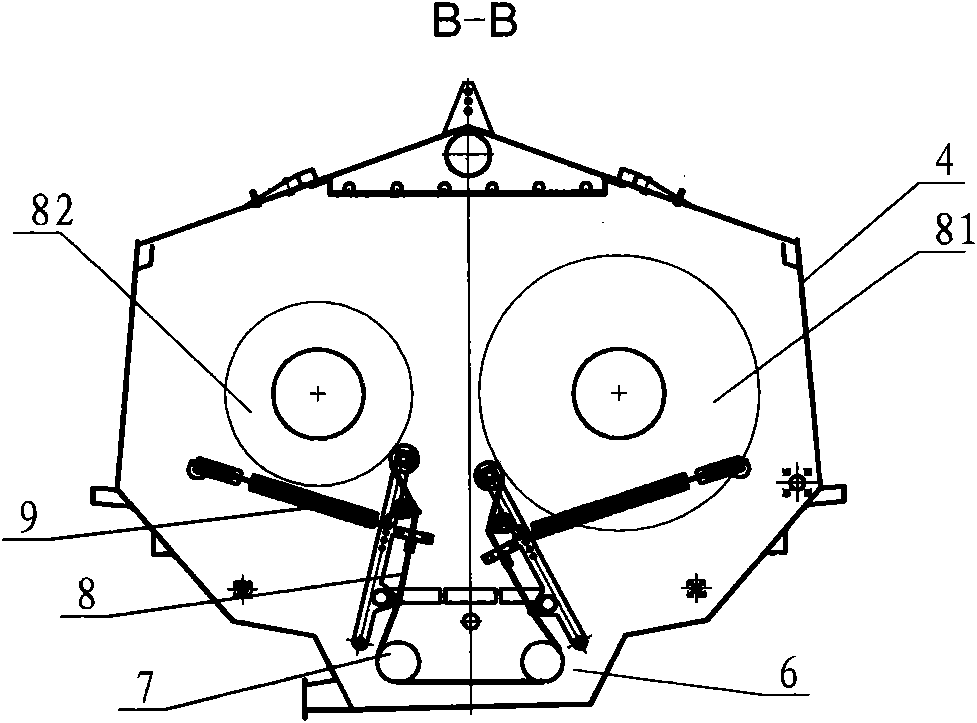

[0014] The present invention as Figure 1-3 As shown, it includes a frame 2, and a pair of cloth winding rollers 5 are arranged horizontally for laying and rewinding the cloth. The frame 2 is provided with a braking device 3 corresponding to the head 51 of the cloth winding roller 5.

[0015] The pair of cloth rolling rollers 5 are provided with a cover body 4 outside, and the lower part of the cover body 4 is provided with a immersion tank 6 , and the head 51 of the cloth rolling roller protrudes out of the cover body 4 .

[0016] It also includes a controller, and the braking device 4 includes an electric, hydraulic or pneumatic driving device, and the electric, hydraulic or pneumatic driving device is connected to the controller.

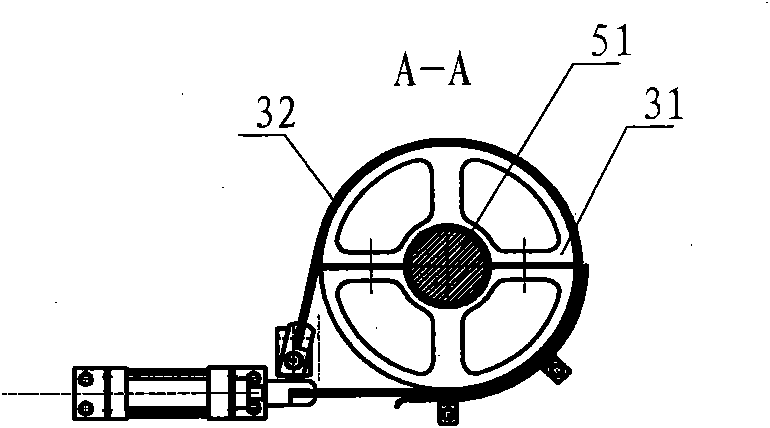

[0017] Wherein the braking mechanism part of braking device 4 can adopt such as image 3 Form brake hub 31, brake band 32, the drive mechanism that drives brake band 32 can be aforementioned electric, hydraulic or pneumatic. The controller calc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap