Construction method of polyethylene grass planting land

A polyethylene and grass technology, applied in the fields of botanical equipment and methods, roads, gardening, etc., can solve the problems of thermal pollution of concrete parking lots, poor ground floor of buildings, and small growth space for grass, so as not to affect the loss of land resources. , the effect of improving the greening rate and reducing the installation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

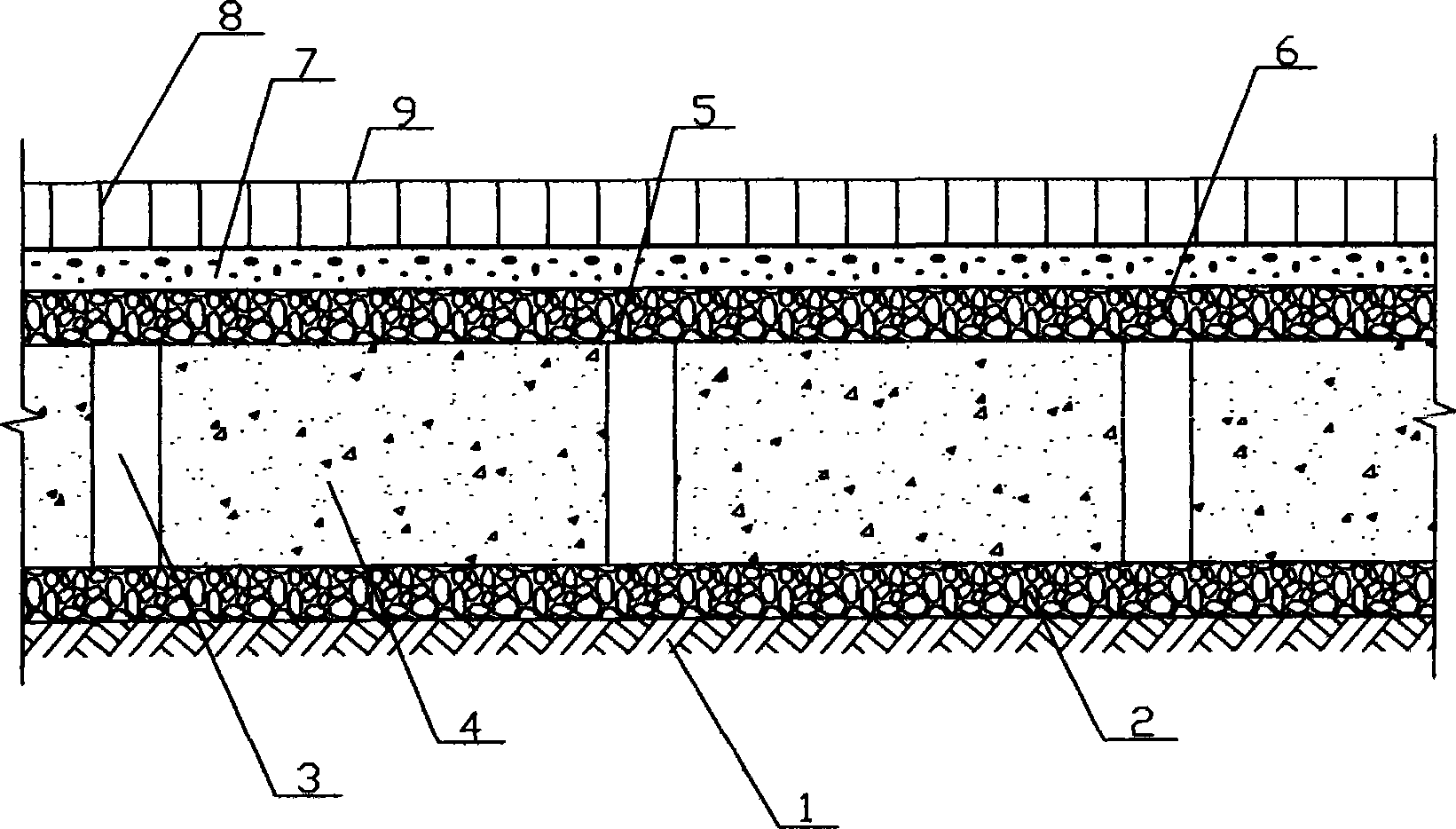

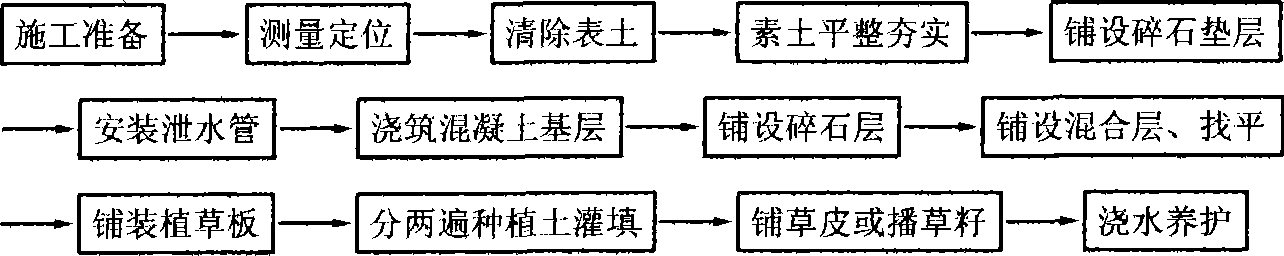

[0021] A polyethylene grass-planting lawn construction method referred to in this embodiment is used for the laying of the parking lot floor. For the structural relationship between the layers, see figure 1 , Lay a grass planting board with a height of 50 or 68 or 70 mm. The construction steps are: construction preparation→measurement and positioning→remove topsoil→plain soil leveling and compacting→laying gravel cushion→install drainpipe→pour concrete base→laying gravel layer → Lay the mixed layer and level it → Pave the grass planting board → Fill with the planting soil twice → Lay the turf or sow the grass seeds → Water and maintain. The construction process is shown in Figure 3. First, construction preparations are made, including various materials, personnel and equipment. Then measure and locate according to the requirements, including the setting of temporary benchmarking points and axis control piles, which should be easy to observe and must be firm, and protective mea...

Embodiment 2

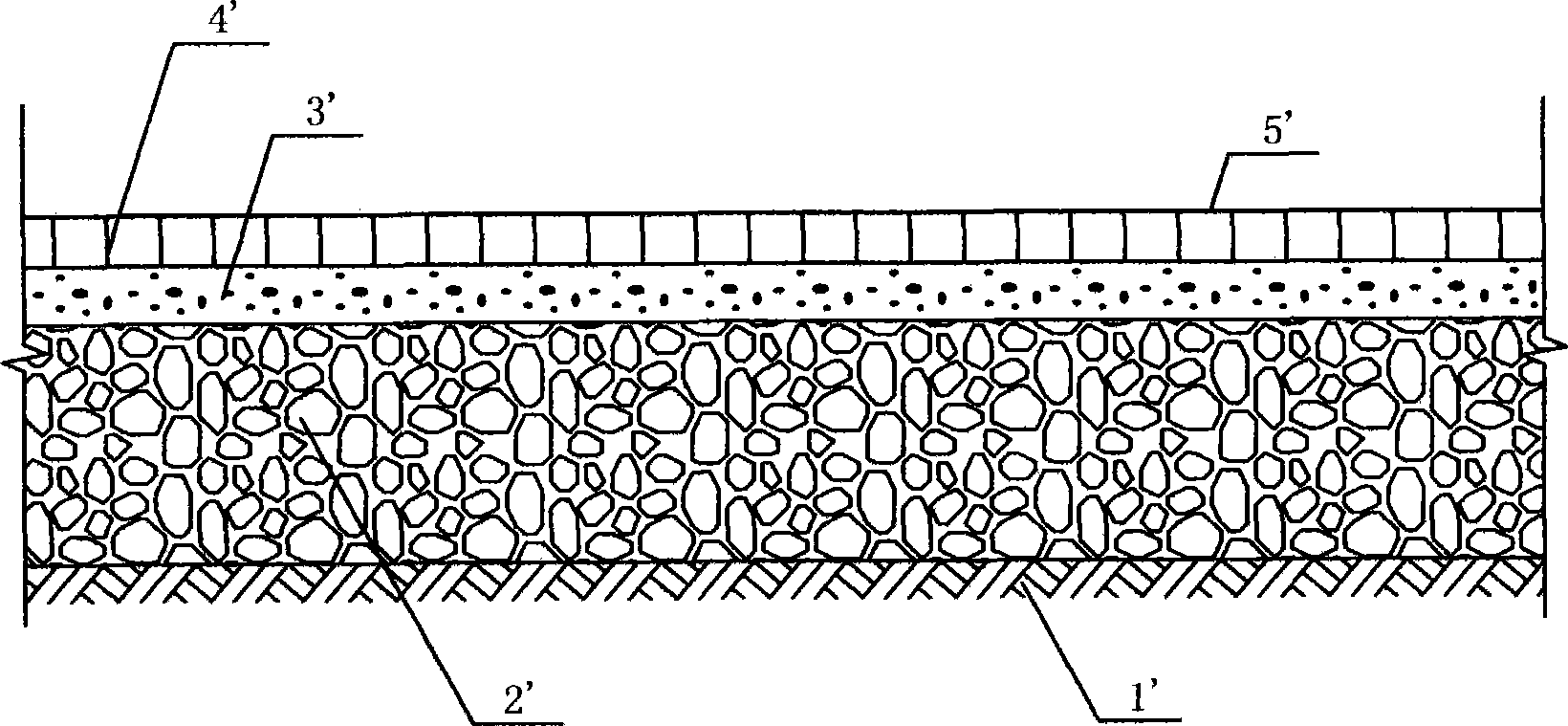

[0023] A polyethylene grass planting lawn construction method referred to in this embodiment is used for the laying of sidewalks and fire exit floors. For the structural relationship between the layers, see figure 2 , laying a grass-planting grid with a height of 35 mm, the construction steps are: construction preparation → measurement and positioning → clearing topsoil → leveling and compacting the plain soil → laying a gravel layer → laying a mixed layer and leveling → paving the grass-planting grid → planting soil irrigation twice Fill → spread turf or sow grass seeds → water and maintain. The construction process is shown in Figure 4. First, construction preparations are made, including various materials, personnel and equipment. Then measure and locate according to the requirements, including the setting of temporary benchmarking points and axis control piles, which should be easy to observe and must be firm, and protective measures should be taken. Then excavate the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com