Main part device of heat storage type porous medium tail gas heat energy recovery micro-emission energy-saving engine

A technology of porous media and heat energy recovery, applied in engine components, exhaust devices, combustion engines, etc., can solve the problems of less micro-emission technology and less product discovery, and achieve the effects of low cost, significant economic benefits and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

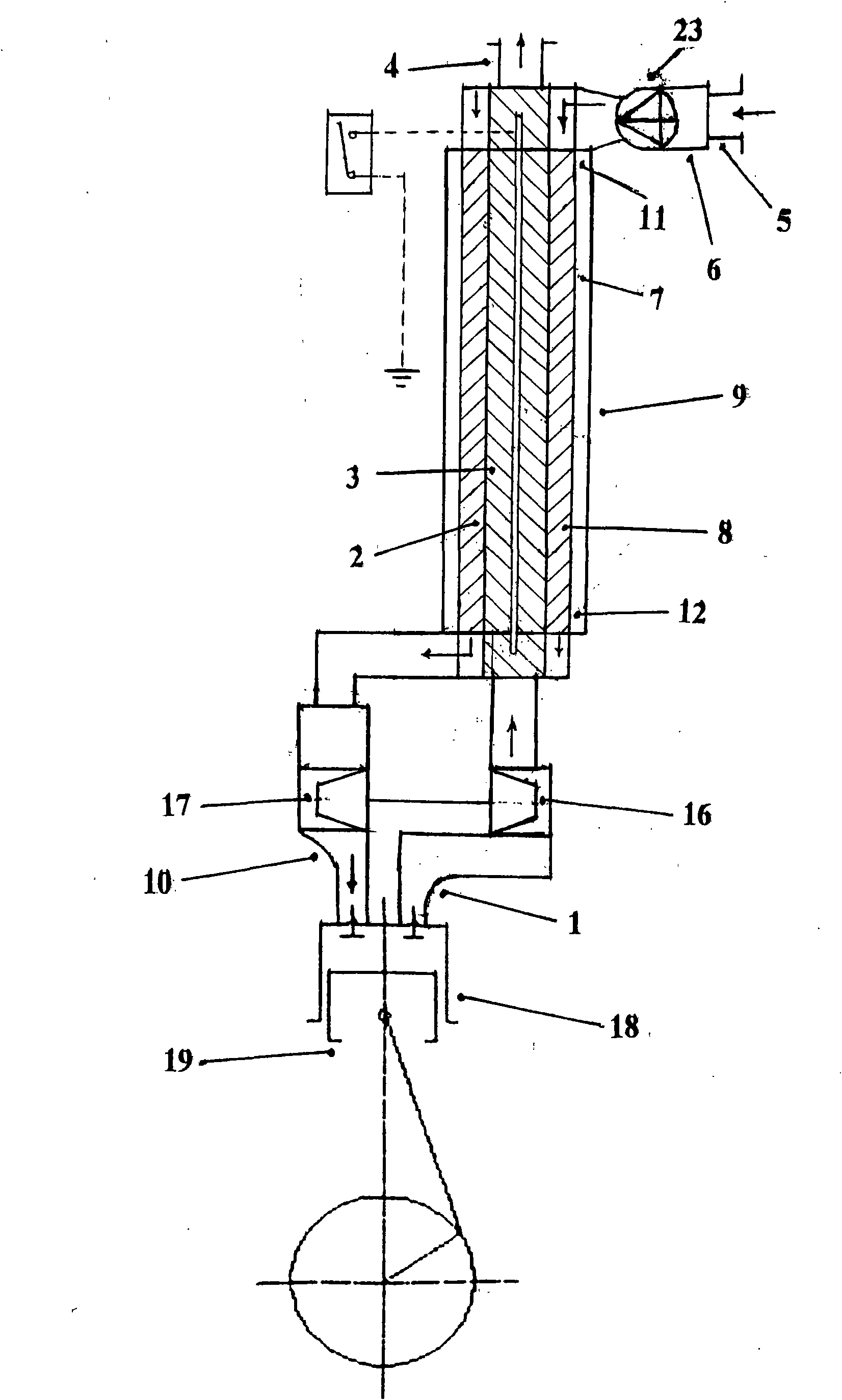

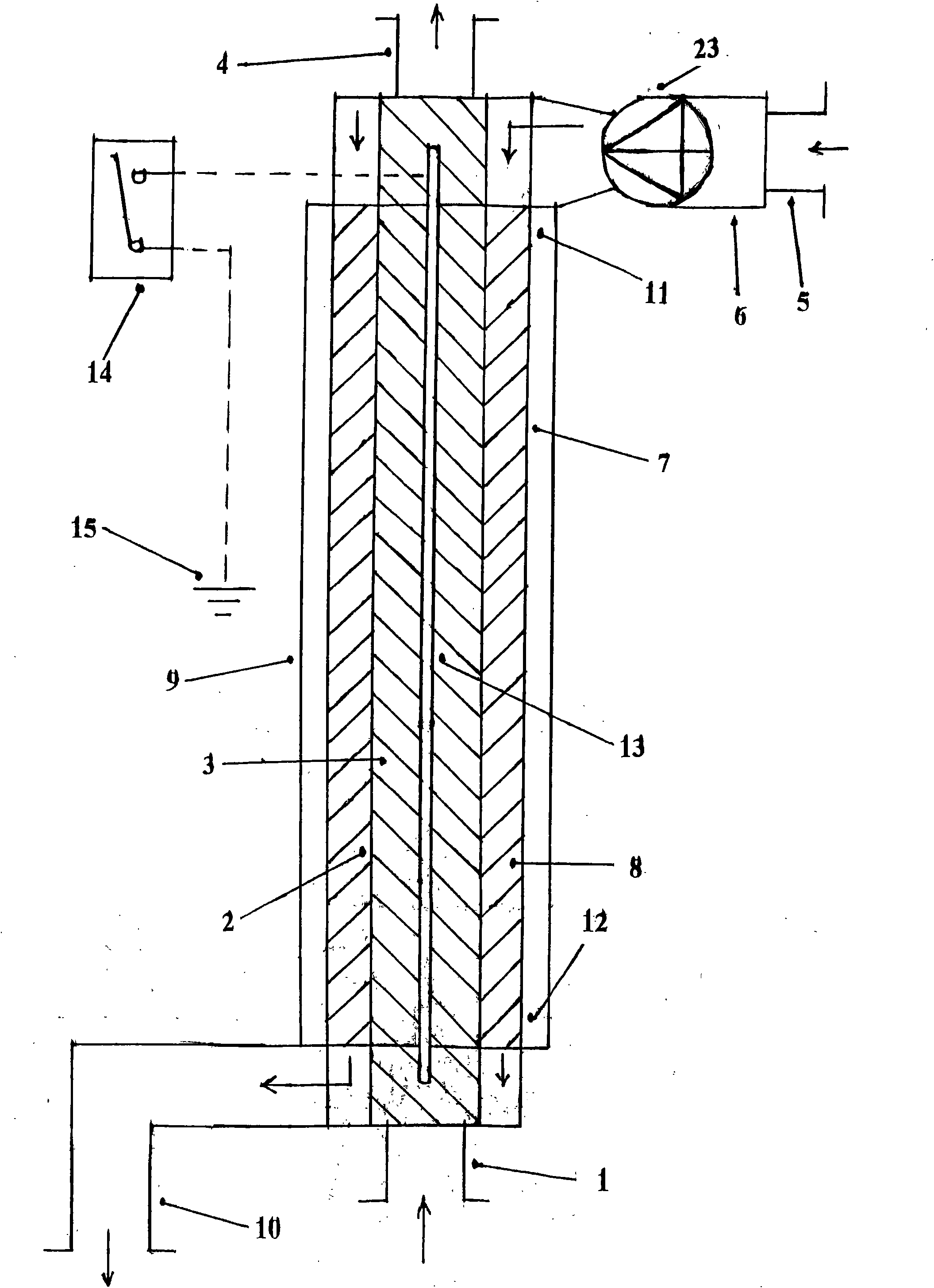

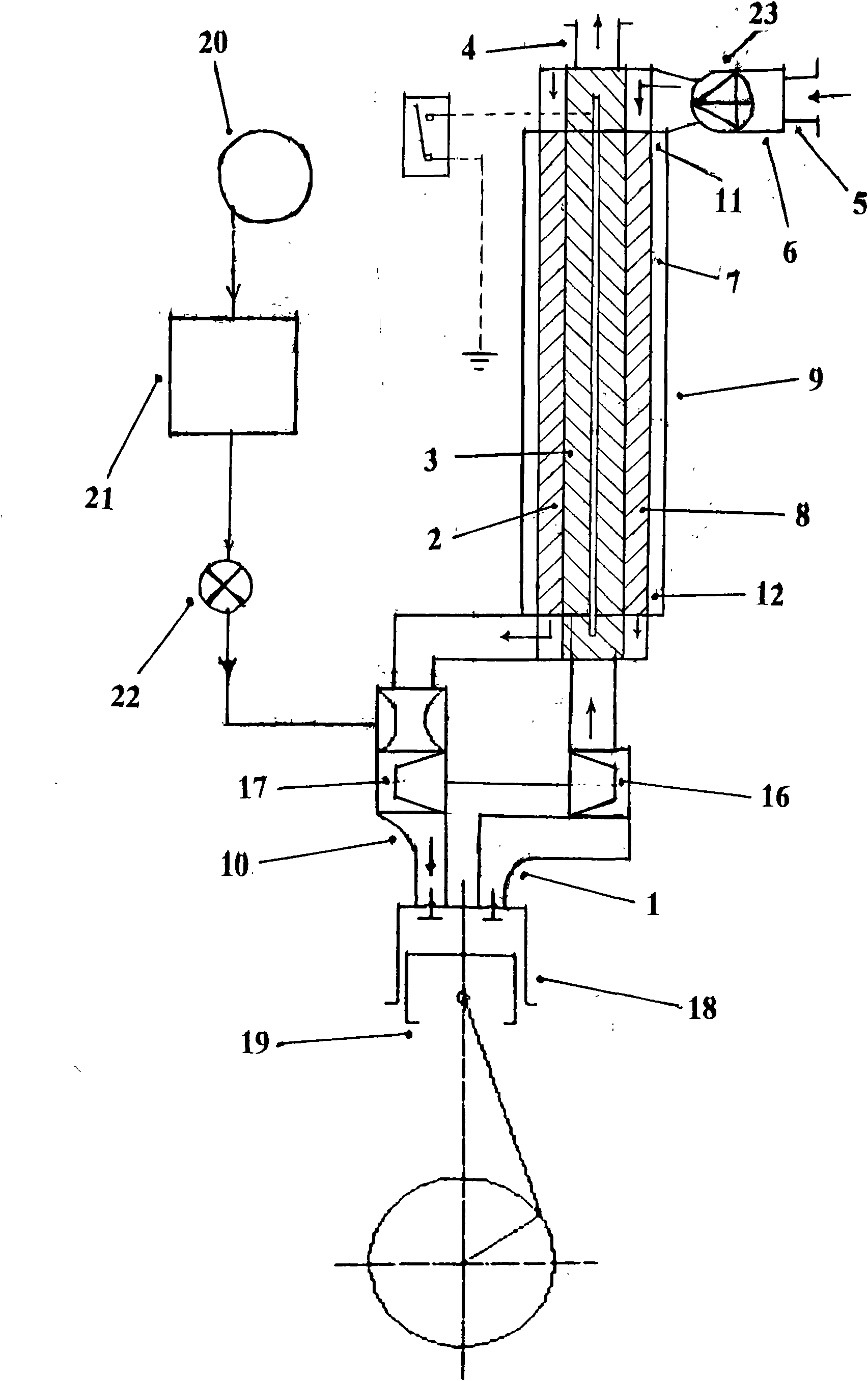

[0013] exist figure 1In the middle, the inner tube porous medium waste heat recovery regenerative body tube (2) and the inner layer porous medium regenerative body (3) are set between the high temperature exhaust gas input pipe (1) and the low temperature residual gas exhaust pipe (4). Tube Porous Media Waste Heat Recovery Heat Storage Body The tube (2) is provided with an inner layer porous medium heat storage body (3). Between the fresh low-temperature air input pipe (5) and the high-temperature air inlet inlet pipe (10) of the engine, an outer pipe porous medium waste heat recovery heat storage body pipe (7), an outer porous medium heat storage body (8), and an outer heat storage body (8) are arranged. Insulation layer (9), an outer porous medium heat storage body (8) is arranged inside the outer porous medium waste heat recovery heat storage body pipe (7), and an outer heat preservation layer is arranged outside the outer porous medium waste heat recovery heat storage body...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap