Method and apparatus for depositing a film using a rotating source

A technology for equipment and thin film materials, applied in the field of depositing thin films and equipment using rotating sources, can solve the problems of low material utilization, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

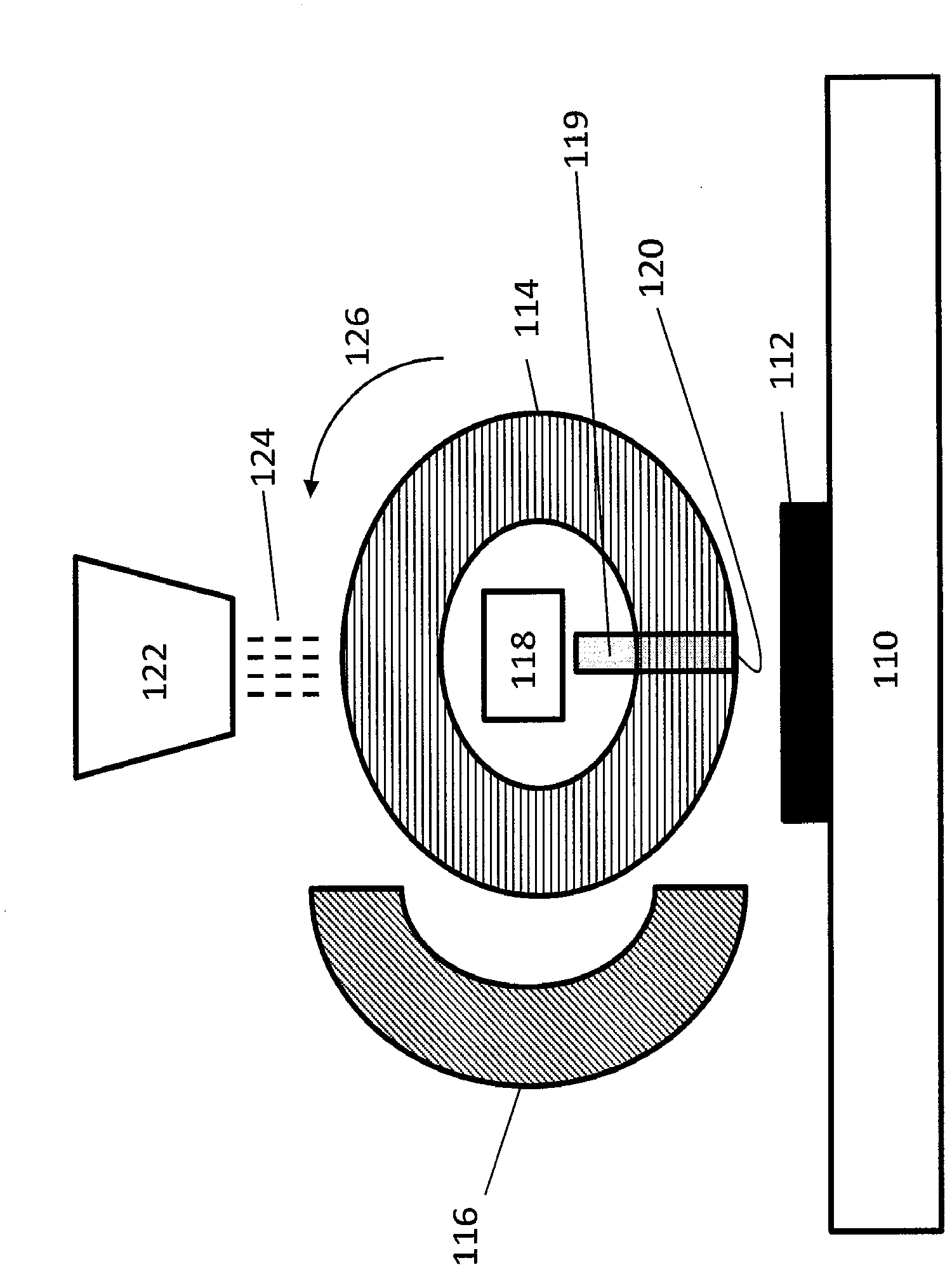

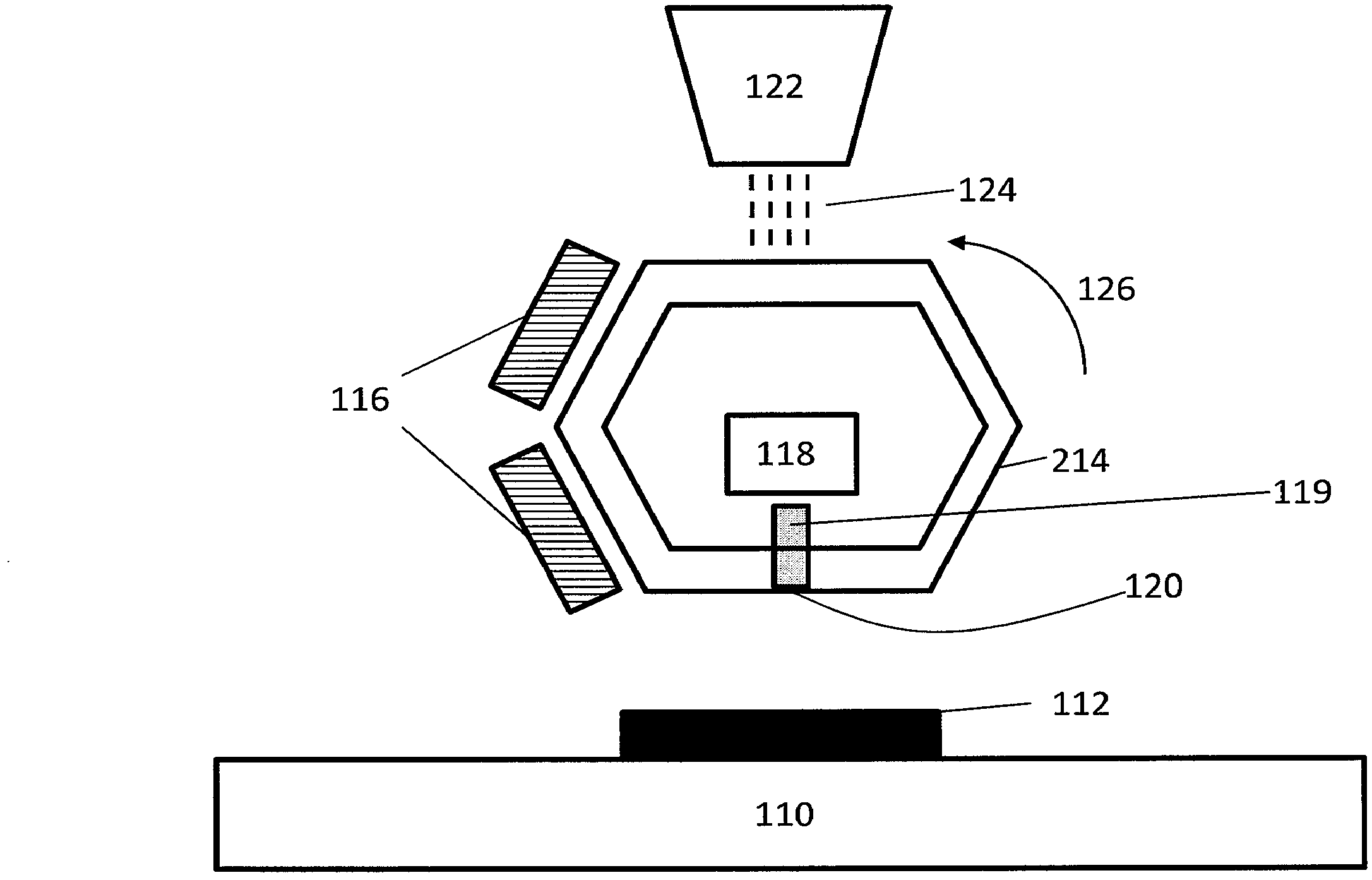

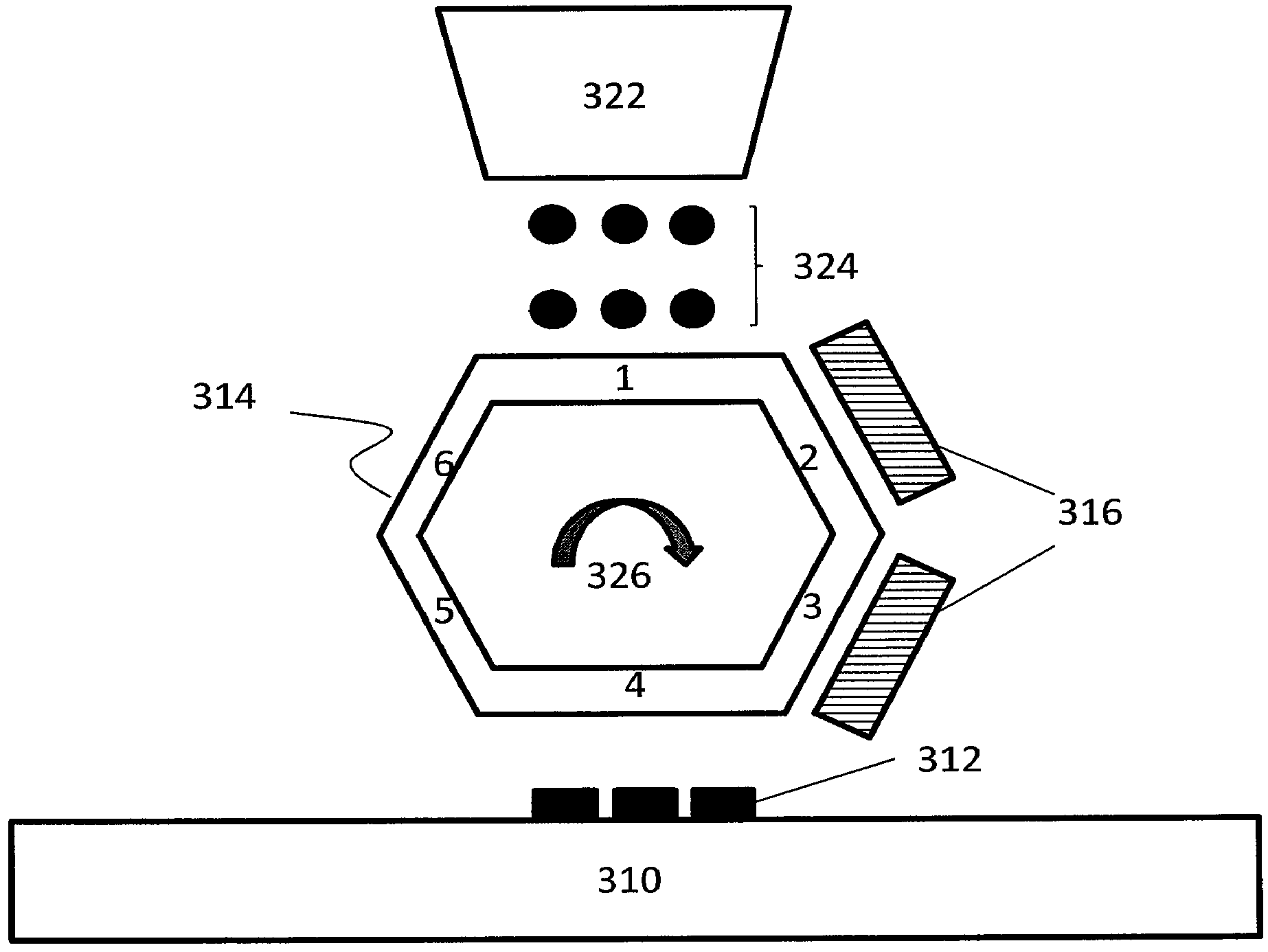

[0038] figure 1 A rotary drum deposition system according to one embodiment of the present disclosure is schematically illustrated. exist figure 1 , the film material supply mechanism 122 measures out the film material. The metered film material 124 can be metered as one or more droplets or as a trickle.

[0039] The film material can be supplied to the transfer surface in the form of solid ink, liquid ink or gaseous vapor ink consisting of pure film material or film material and non-film material (otherwise referred to as "carrier material"). The use of ink is beneficial because it provides the film material to the transfer surface with one or more non-film materials for processing the film material before it is deposited on the substrate. The thin film material may consist of OLED material. The film material may comprise a mixture of materials. The carrier material may also comprise mixtures of materials.

[0040] An example of a liquid ink is a thin film material diss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com