Method and apparatus in connection with a refuse chute

A technology of garbage chute and equipment, which is applied in the fields of garbage chute, movement of domestic waste, collection and movement of waste materials, and can solve problems such as broken waste bags, noise hazards, dirty garbage chute, etc., so as to maintain good operation and reduce waste Minor fire and explosion hazard, reduced inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

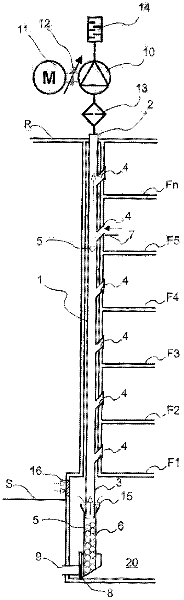

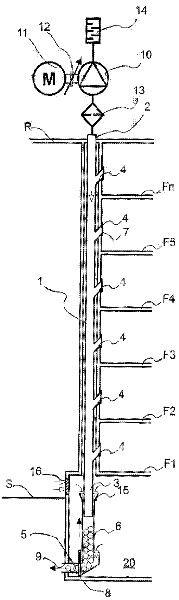

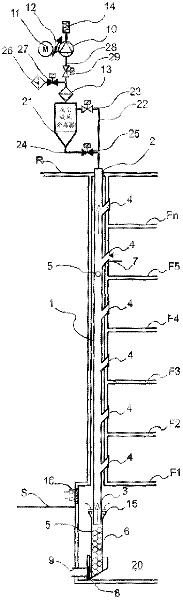

[0028] figure 1 and 2 A simplified and cut-away embodiment of the solution according to the invention is shown. The refuse chute 1 of the material moving system is present in these figures. The refuse chute 1 extends vertically through the floors F1 . . . Fn of the building, in which case the top end 2 of the refuse chute extends eg to the roof R of the building. The bottom end 3 of the refuse chute 1 extends into a space 20 in the bottom of the building, for example a basement. In this figure, the surface of the ground is identified by the letter S. One or more inlet openings 4 are arranged in the refuse chute 1 . The refuse chute 1 in the figures is a section of a pipeline arranged in place in a building.

[0029] The material is fed into the refuse chute via one or more feed holes 4 . The opening means 7 analogously can be connected to the input opening 4 . Furthermore, a valve device V can be connected to the inlet opening, via which valve device the feed of materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com