Method and arrangement in a pneumatic material conveying system

A conveying system and material technology, applied in the direction of conveyors, transportation and packaging, conveying bulk materials, etc., can solve problems such as blocking openings and difficulties, and achieve the effects of reducing energy demand, fast and effective emptying, and good propulsion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

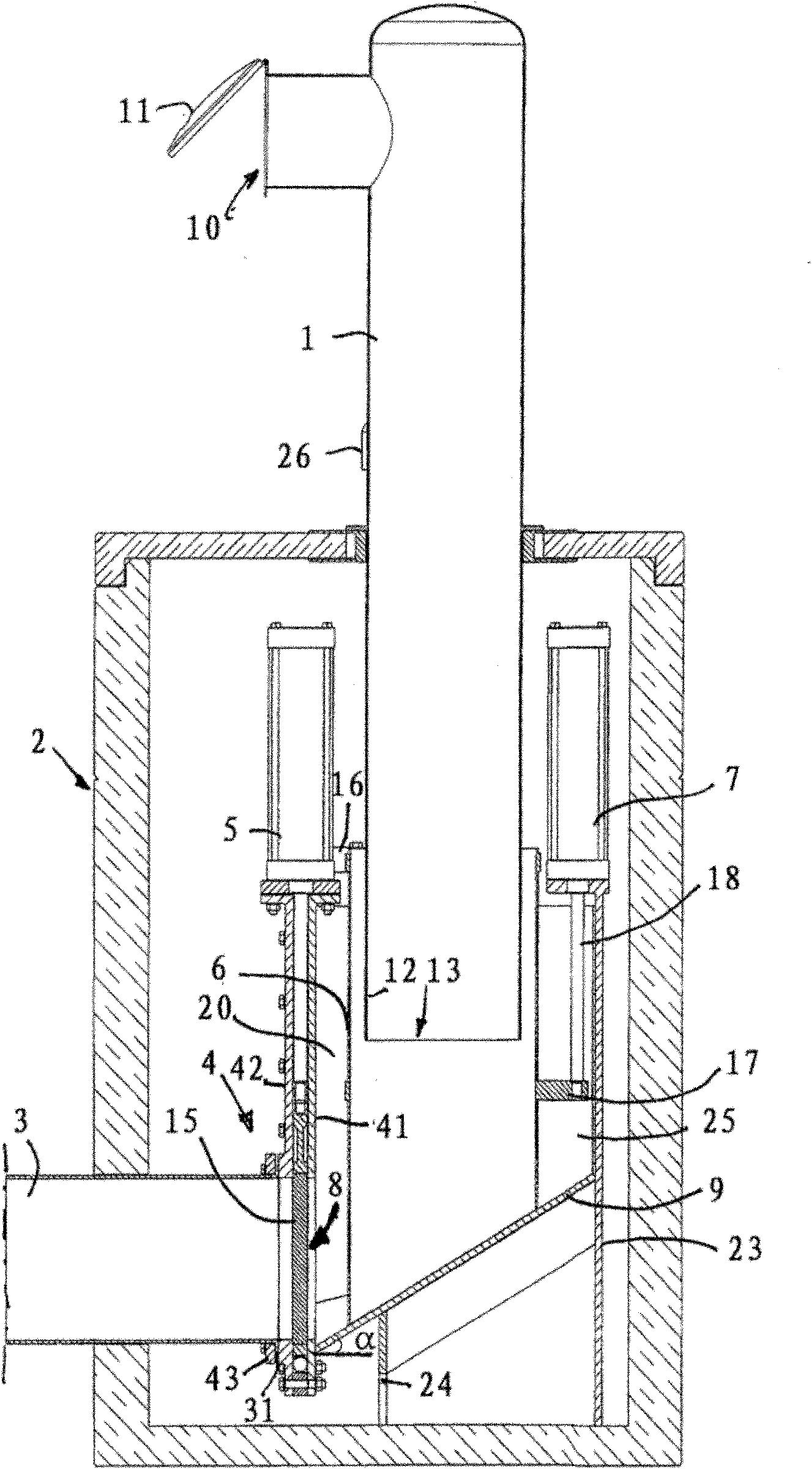

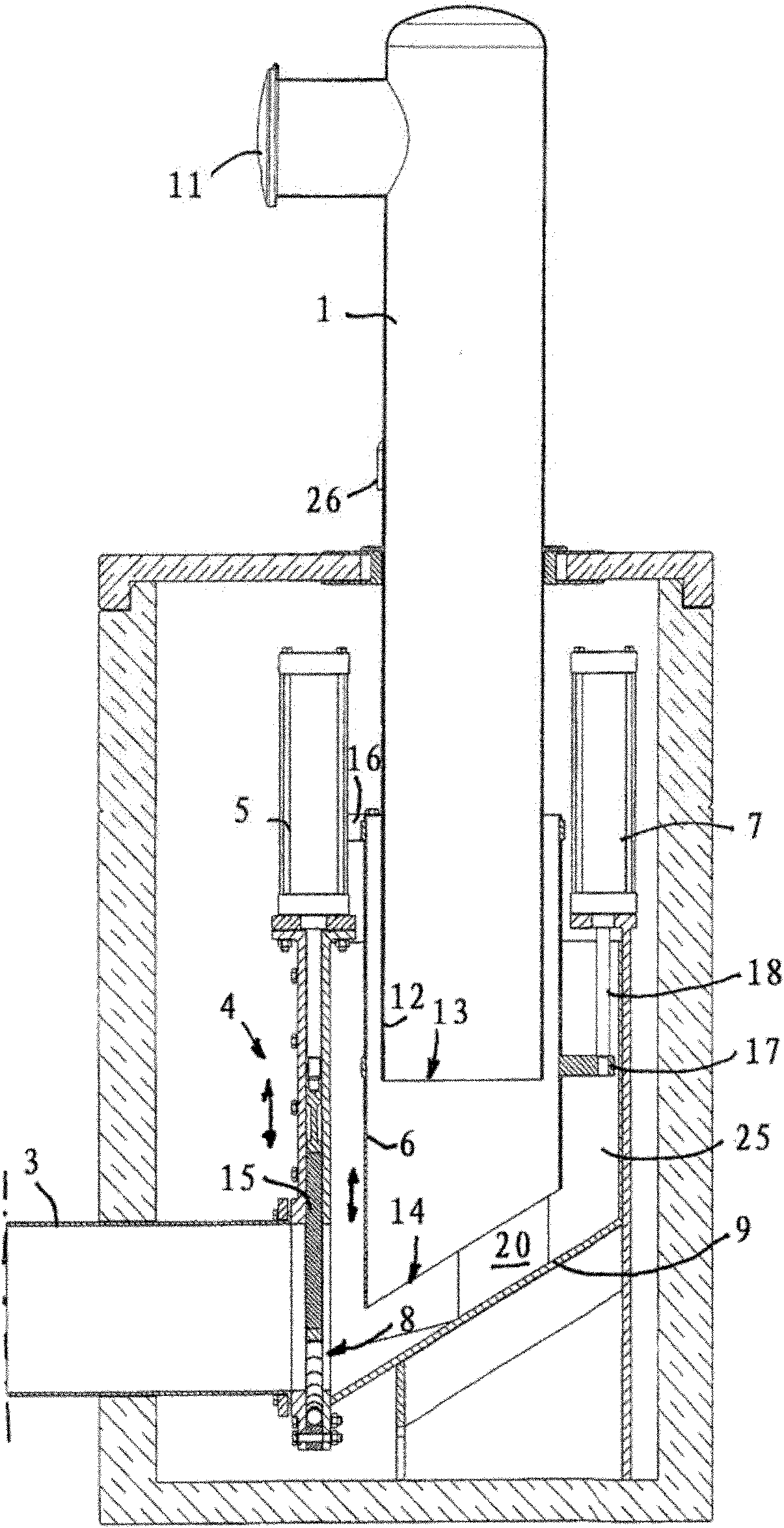

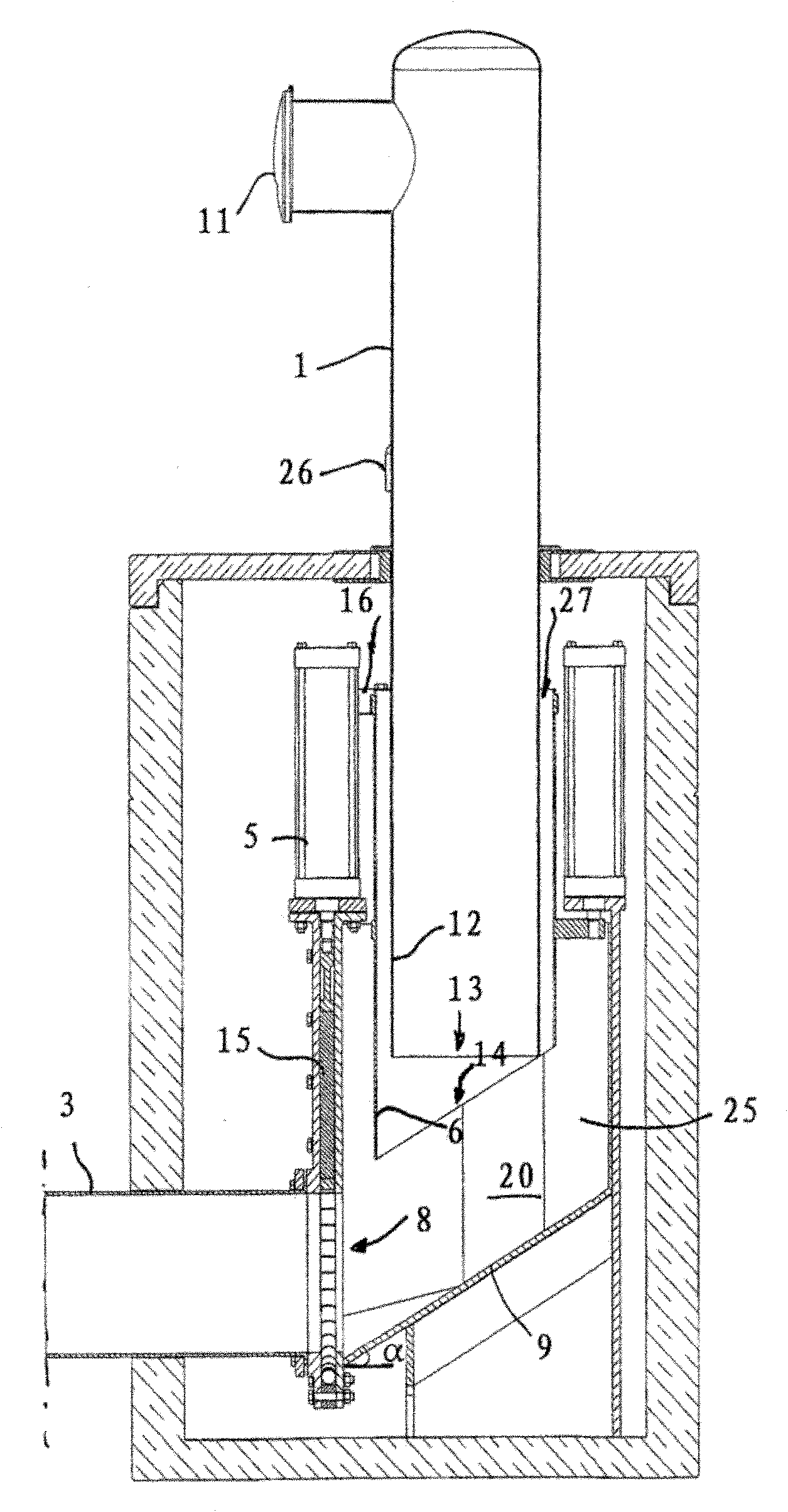

[0018] Figure 1-3 and 5 show a first embodiment of the supply box 2 connected to the feed chute 1 in the material conveying system according to the invention. The supply box 2 comprises a material space 20 which is connected to the delivery pipe 3 . An outlet valve 4 is located between the delivery pipe 3 and the material space 20 of the supply tank 2 , which outlet valve 4 is driven by an actuator 5 . The material space 20 of the feed box is delimited by a wall 25 . At least one feed chute 1 is provided in the supply box material space via the upper part of the material space 20 , through which material is guided into the material space. In the feed chute at least one feed hole 10 is arranged through which material is fed to the feed chute. In the embodiment shown in the figures, a cover 11 is arranged in connection with the feed hole. In the lower part of the material space 20 of the supply box 2 there is an outlet 8 through which the material is conveyed from the suppl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com