Electronic potentiometer and calibration method thereof

An electronic potentiometer and calibration method technology, which is applied in the field of sensors, can solve the problems of high uniformity of coil winding, difficult to adjust the potential level accurately, difficult linearity adjustment, etc., and achieve simple and novel calibration methods, convenient debugging, and easy Achieved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

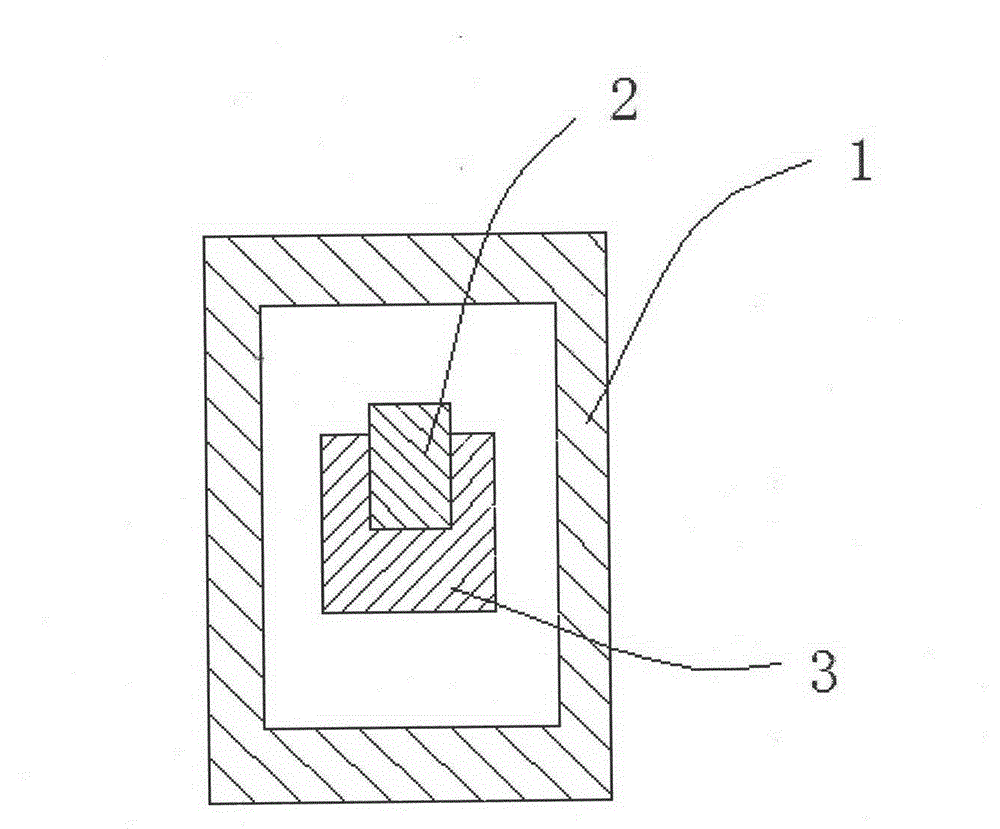

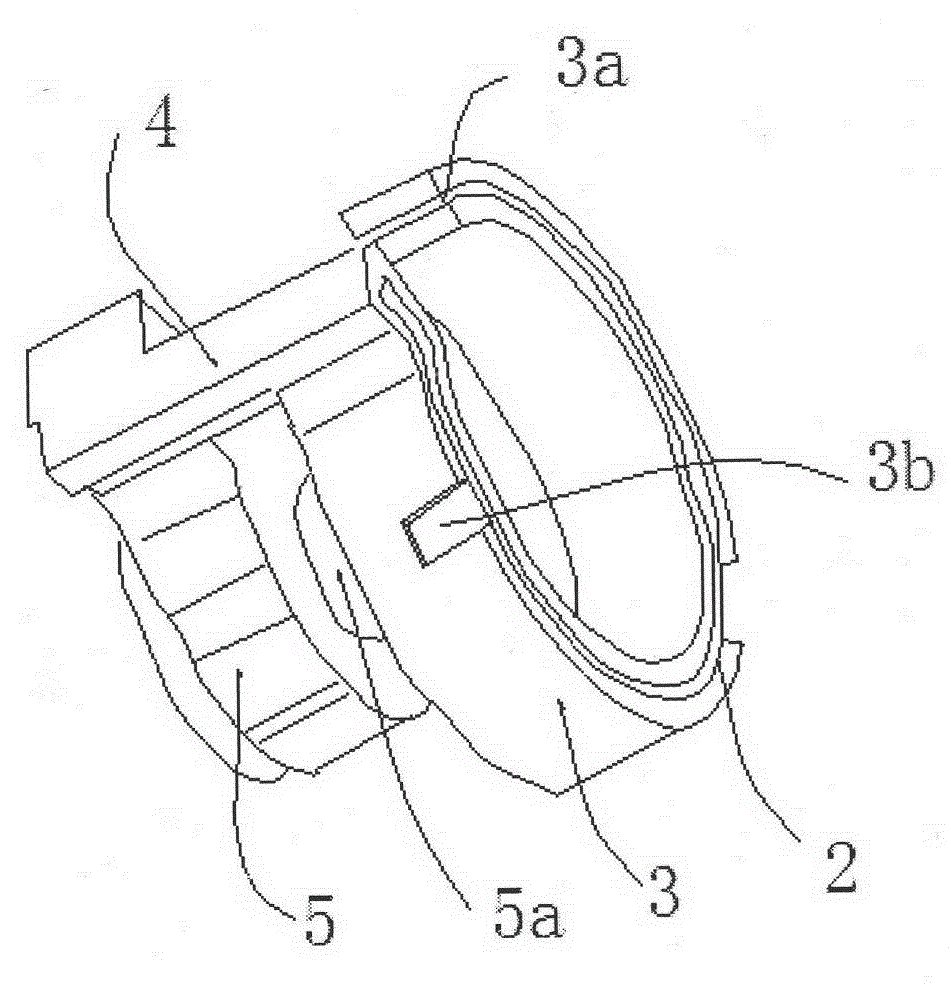

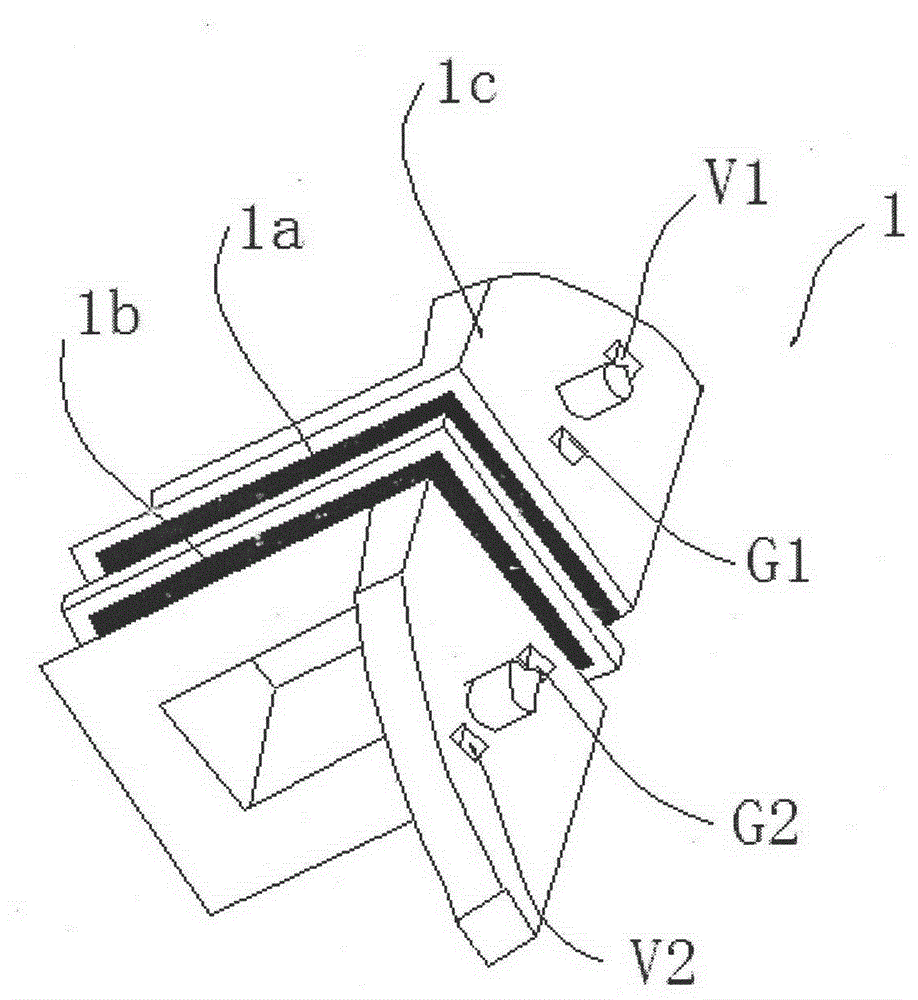

[0034] Such as figure 1 with Figure 4 As shown, an electronic potentiometer includes a coil 1, a magnetically conductive sheet 2, a support frame 3, etc., a support frame 3 is pierced in the inner cavity of the coil 1, and the magnetically conductive sheet is fixed on the support frame 3. sheet 2, the support frame 3 can drive the magnetic conductive sheet 2 to move in the inner cavity of the coil 1 .

[0035] Such as figure 2 with Figure 4As shown: the support frame 3 has a "C"-shaped structure, and a "C"-shaped magnetic guide sheet installation bar groove 3a is opened on the upper end surface of the support frame 3, and the magnetic guide sheet 2 is embedded and fixed in the guide The magnetic sheet is installed in the bar groove 3a; certainly the above-mentioned support frame 3 is not necessarily in a "C" shape structure, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com