Preparation process for tea polyphenol metal complex

A metal complex and preparation technology, applied in the direction of calcium organic compounds, zinc organic compounds, etc., can solve the problems of easy oxidation of tea polyphenols, large solvent consumption, agglomeration, etc., and achieve the effect of no three wastes and fewer process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Preparation process of tea polyphenol zinc complexes: take 5.0 g of Xinyang tea leaves, extract 3 times with 100 g of distilled water in a water bath at 70°C, filter the tea soup, combine the tea soup, and add 3.0 g of ZnSO 4 ·7H 2 O, after magnetic stirring and dissolving, add 1 mol / L Na dropwise while stirring 2 CO 3 The pH of the solution was adjusted to 5, the reaction was stopped for 30 minutes, the stirring was stopped, and the filter cake was washed with water, ethanol and acetone in sequence, and the filter cake was vacuum-dried to obtain 0.65 g of brown-yellow tea polyphenol zinc complex.

[0030] Using gallic acid as the reference substance, the mass content of tea polyphenols in the tea polyphenol zinc complex was determined by ferrous tartrate spectrophotometry to be 22.80%; the mass content of zinc was determined to be 14.43% by EDTA complexometric titration.

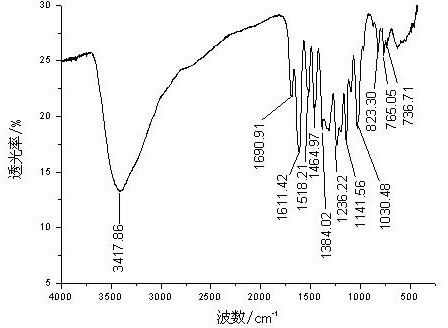

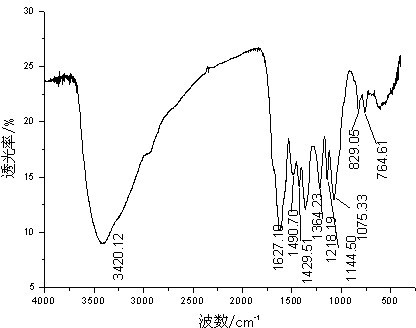

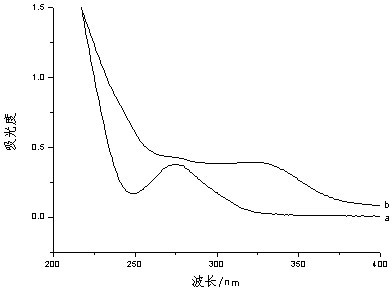

[0031] Infrared spectrum of tea polyphenols figure 1 As shown, the obtained tea polyphenol zin...

Embodiment 2

[0036] Preparation process of tea polyphenol zinc complexes: take 5.0 g of Xinyang tea leaves, extract 3 times with 50 g of distilled water in a 75°C water bath, and filter to obtain tea soup, combine the tea soup, add 0.5 g of zinc chloride to the tea soup, and magnetically stir to dissolve Add 1 mol / L NaHCO dropwise while stirring 3 Adjust the pH of the solution to 5.5, stop stirring after 40 minutes of reaction, filter with suction, wash the filter cake with water, ethanol, and acetone in sequence, and vacuum-dry the filter cake to obtain 0.58 g of brown-yellow tea polyphenol zinc complex.

[0037] Using gallic acid as the reference substance, the mass content of tea polyphenols in the tea polyphenol-zinc complex was determined by ferrous tartrate spectrophotometry to be 14.60%; the mass content of zinc was determined to be 9.26% by EDTA complexometric titration.

[0038] The infrared spectrogram of the tea polyphenol zinc complex that makes is as follows Figure 5 shown. ...

Embodiment 3

[0040] Preparation process of tea polyphenol zinc complex, take 5.0 g of Xinyang tea leaves, extract 3 times with 70 g of distilled water in a water bath at 80°C, filter the tea soup, combine the tea soup, add 3.0 g of zinc acetate to the tea soup, and magnetically stir to dissolve it. Add 1 mol / L KHCO dropwise while stirring 3 Adjust the pH of the solution to 6, stop stirring after 50 minutes of reaction, filter with suction, wash the filter cake with water, ethanol, and acetone in sequence, and vacuum-dry the filter cake to obtain 0.63 g of brown-yellow tea polyphenol zinc complex.

[0041] Using gallic acid as the reference substance, the mass content of tea polyphenols in the tea polyphenol-zinc complex was determined by ferrous tartrate spectrophotometry to be 24.58%; the mass content of zinc was determined to be 16.77% by EDTA complexometric titration.

[0042] The infrared spectrogram of the tea polyphenol zinc complex that makes is as follows Figure 6 shown.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap