Hole cover fixation structure capable of preventing stopper rotation in disassembly process

A technology of fixing structure and hole radius, applied in the field of hole cover fixing structure, can solve the problems of blocking rotation by applying external force, blocking and rotating together with screws, inconvenient use, etc., and achieves the effect of overcoming inconvenience in use and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with specific embodiments.

[0014] In this embodiment, the hole cover fixing structure proposed by the present invention is applied to the opening on the outer surface of the shell of a certain type of product.

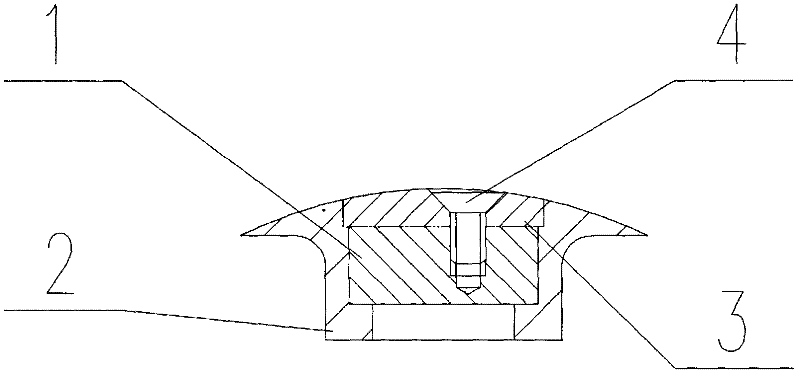

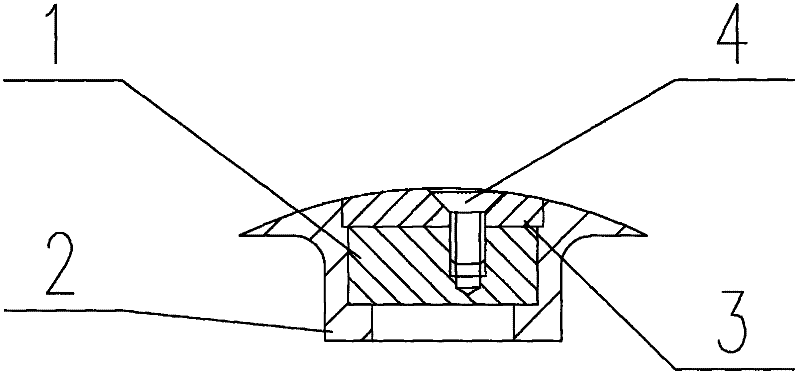

[0015] The product casing 2 in this embodiment is a revolving body structure, and a plug 1 is plugged in the opening on the outer surface of the casing. The plug 1 is a cylindrical structure, and the central axis of the plug coincides with the central axis of the opening on the outer surface of the casing; the hole cover 3 is capped on the opening on the outer surface of the housing, and the outer surface of the hole cover 3 and the outer surface of the housing are smoothly transitioned to ensure the smooth aerodynamic shape of the overall product housing. For openings with a diameter of less than 40 mm in this embodiment, a single screw 4 is used to securely connect the hole cover with the plug, wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com