FIFO (Fast-In Fast-Out) efficient filter-cloth filter-plate pressure filter and high-speed feeding method

A feeding method and filter press technology, which are applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems of inability to achieve rapid feeding, and achieve energy consumption, high feeding efficiency, and smooth feeding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

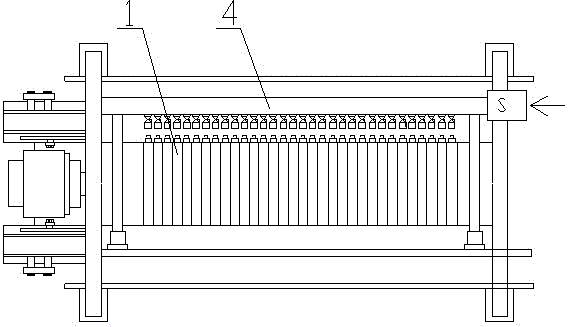

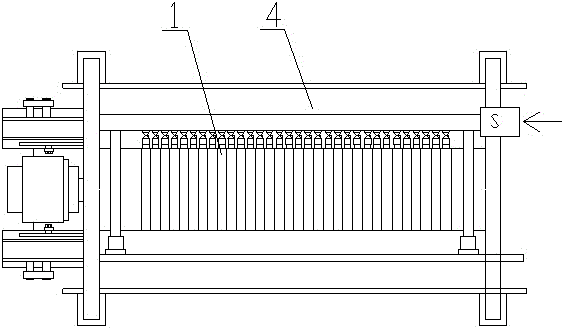

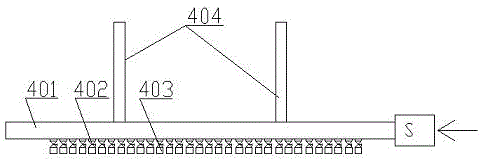

[0015] Embodiment 1: with reference to attached Figure 1-6 . A high-input and fast-out high-efficiency filter cloth filter plate filter press, which includes a filter cloth filter plate filter press, and a plurality of filter cloth filter plates in the filter cloth filter plate group 1 in the filter cloth filter plate filter press The upper end is provided with a material inlet 2, and the lower part is provided with a material outlet 3. The vertical lifting feeding assembly 4 is located above the feeding inlet of the filter cloth filter plate group 1 and is connected to multiple feeding nozzles below the feeding assembly 4. 403 are respectively matched with the feed inlets 2 of multiple filter cloth filter plates in the filter cloth filter plate set 1. The feed port 2 in the filter cloth filter plate 1 is directly connected to the pressing chamber of the filter cloth filter plate, and a feed valve is installed on the feed port 2 . The feed valve 2 is a one-way valve or an e...

Embodiment 2

[0016] Embodiment 2: On the basis of Embodiment 1, the one-way valve is composed of a pipe joint and a tapered rubber sleeve. The upper part of the pipe joint is a feed butt joint socket located outside the filter plate, and the lower part is covered with a high-elastic conical rubber head. And located in the filter plate, the cone head of the conical rubber head is stretched under the pressure of the high-pressure material fluid, and automatically returns to its original shape after the feeding is completed-that is, it is closed to prevent the material from flowing backward.

Embodiment 3

[0017] Embodiment 3: On the basis of Examples 1 and 2, a high-speed feeding method of a high-input and fast-out high-efficiency filter cloth filter plate filter press, it includes a filter press, and in the filter cloth filter plate filter press The upper part of the multi-piece filter cloth filter plate in the filter cloth filter plate group 1 is provided with a feed port 2, and the lower part is provided with a discharge port 3, and the vertical lifting feeding assembly 4 is located at the feed port 2 of the filter cloth filter plate group 1. The multiple feed ports 403 above and connected to the bottom of the feed assembly 4 are respectively matched with the feed ports 2 of the multiple filter cloth filter plates in the filter cloth filter plate group 1. When the filter cloth in the filter cloth filter plate group 1 When the material cavity formed between the filter plate and the filter cloth filter plate needs to be fed, the controller 5 instructs the lifting driving mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com