Work-piece interchanging manipulator of hydraulic drawing machine

A technology of manipulators and stretching machines, applied in the field of manipulators, can solve the problems of low flexibility, rare multi-station hydraulic stretching machines, and poor operability, and achieve high flexibility, simple structure, and convenient and free operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

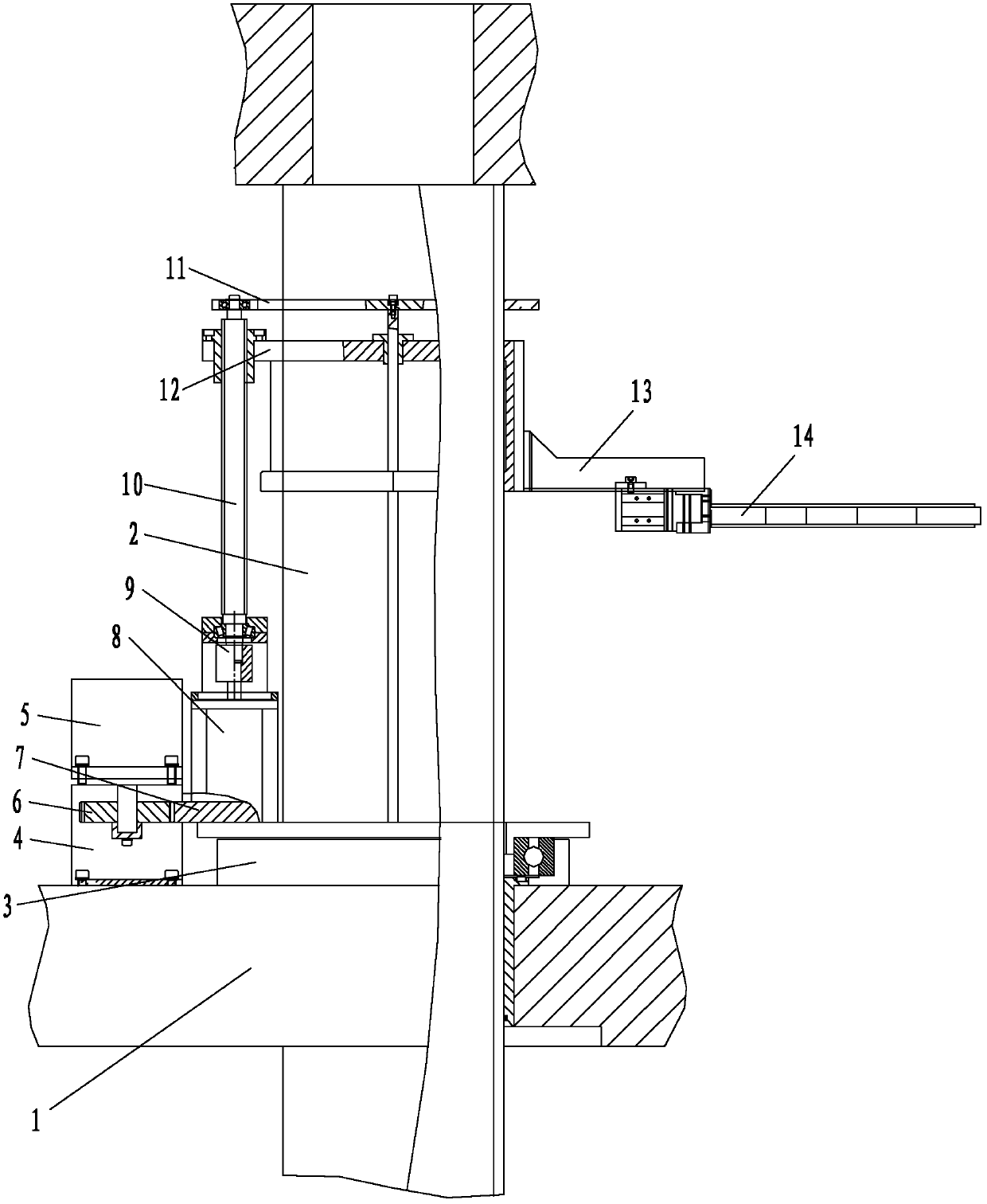

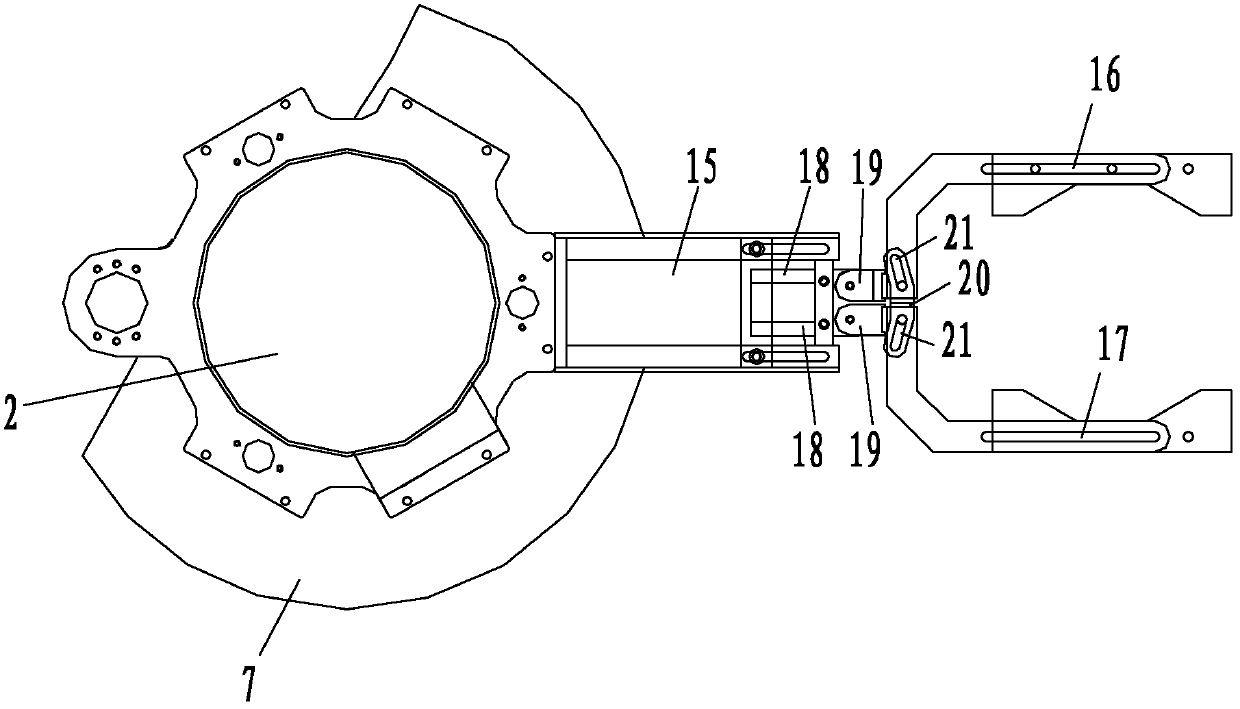

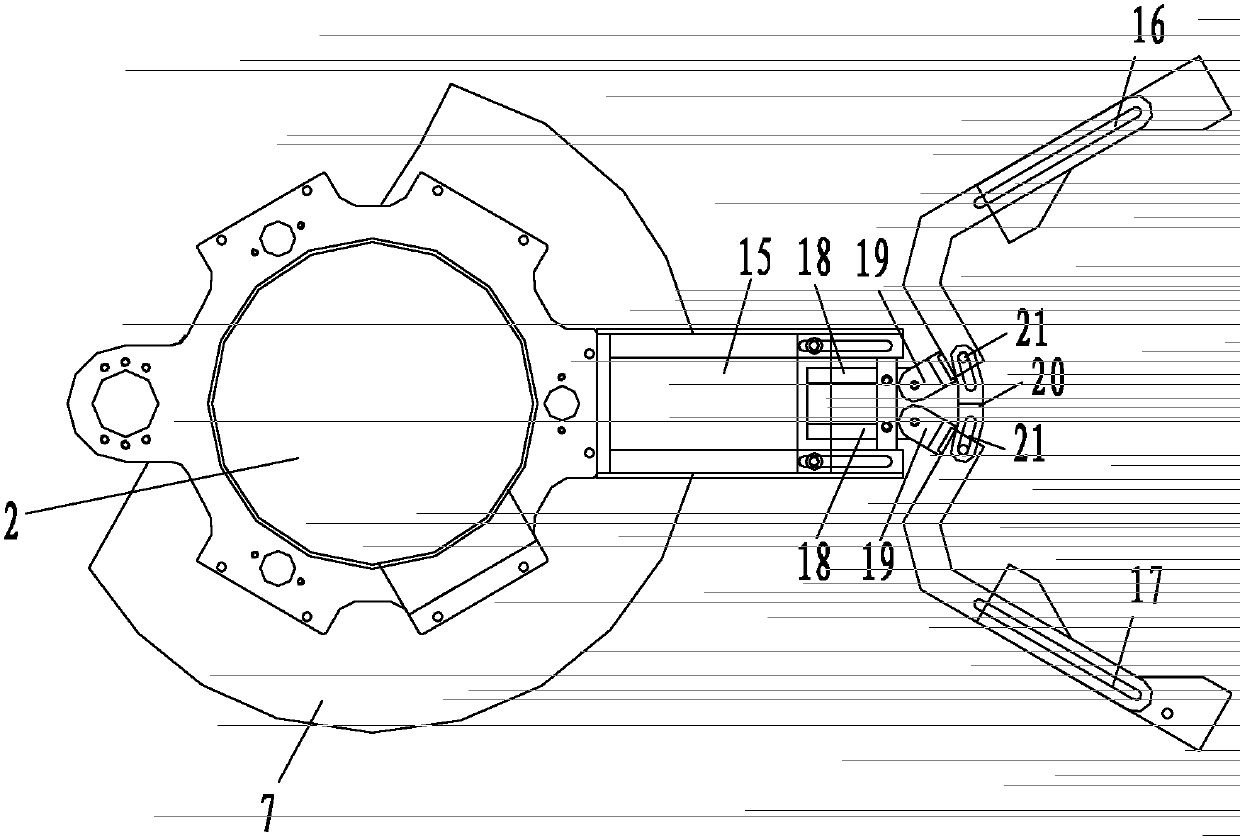

[0013] as attached figure 1 , 2 , 3 shows a hydraulic drawing machine workpiece transposition manipulator of the present invention, including worktable 1, middle column 2, base 3, first motor mount 4, first motor 5, pinion 6, sector gear 7. The second motor mounting seat 8, the second motor 9, the screw rod 10, the upper positioning plate 11, the manipulator mounting sleeve 12, the manipulator mounting frame 13, and the manipulator assembly 14; the base 3 is arranged on the worktable 1; The middle column 2 is arranged through the base 3 and the worktable 1, and is located at the center of the base 3; the sector gear 7 is rotatably arranged on the base 3; the first motor mount 4 is arranged on the worktable 1; the first motor 5 is set on the first motor mount 4; the pinion 6 is set on the output shaft of the first motor 5; the pinion 6 meshes with the sector gear 7; the second The motor mount 8 is arranged on the upper surface of the sector gear 7; the second motor 9 is dispo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com