Novel extrusion process for hexagonal shouldered self-locking nut

A technology of self-locking nuts and hexagonal strips, which is applied in the direction of nuts, threaded fasteners, connecting components, etc., can solve the problem of unstable flat dimensions of hexagonal shoulder self-locking nuts, failure to ensure product quality, and product self-locking torque Difficult to guarantee and other problems, to achieve the effect of dimensional stability, thread prevention, and adjustable action time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] A new type of flattening process for hexagonal shoulder self-locking nuts, the steps are as follows:

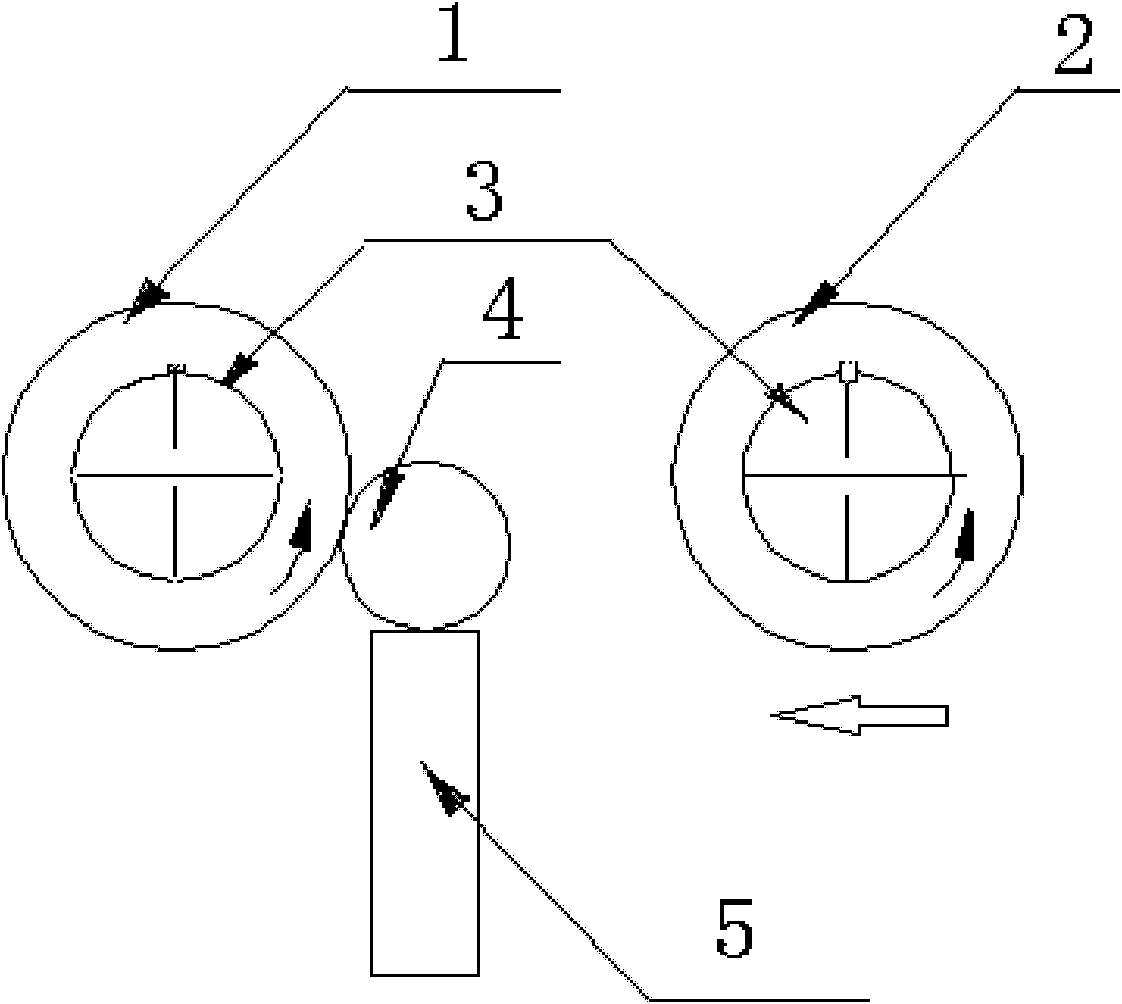

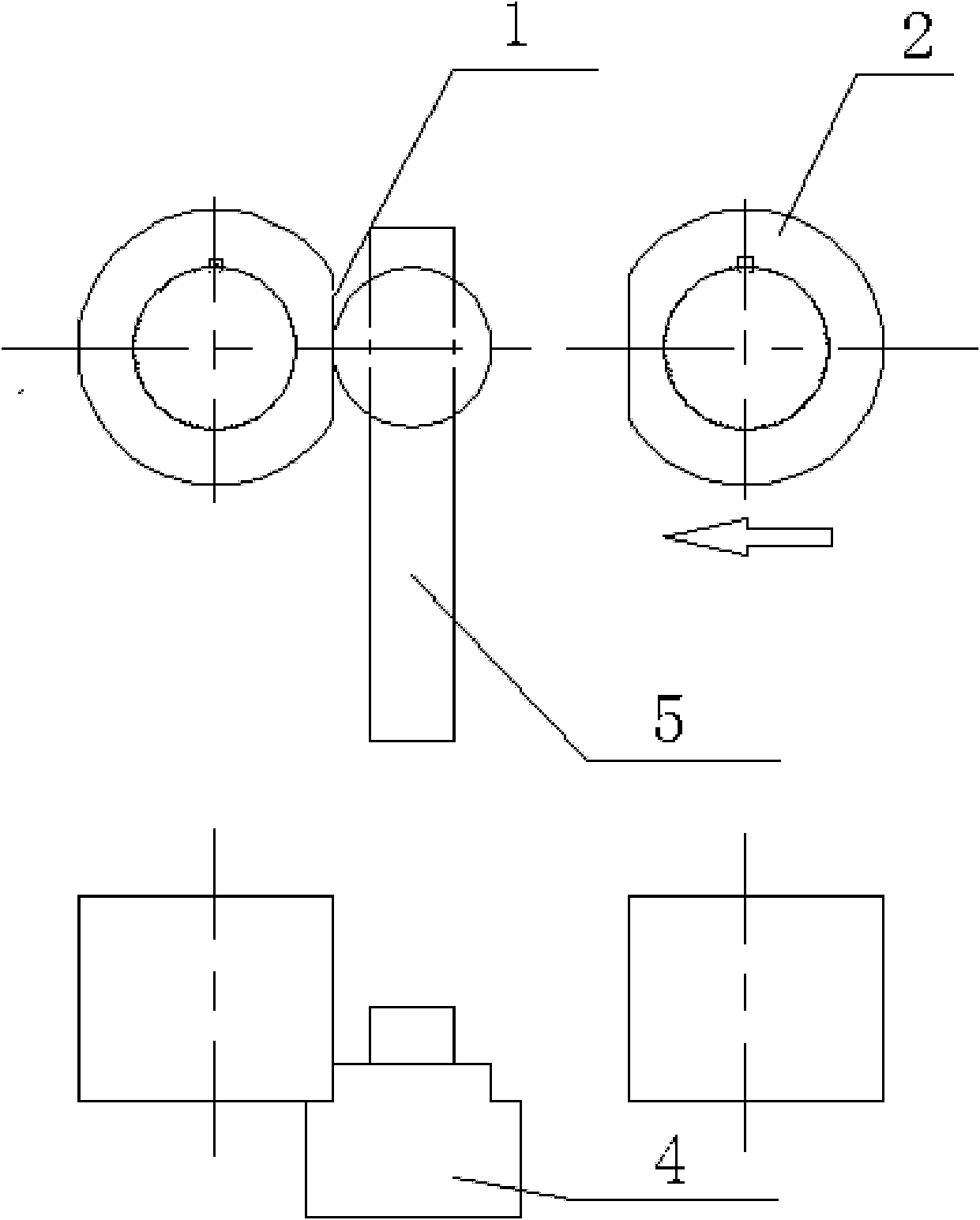

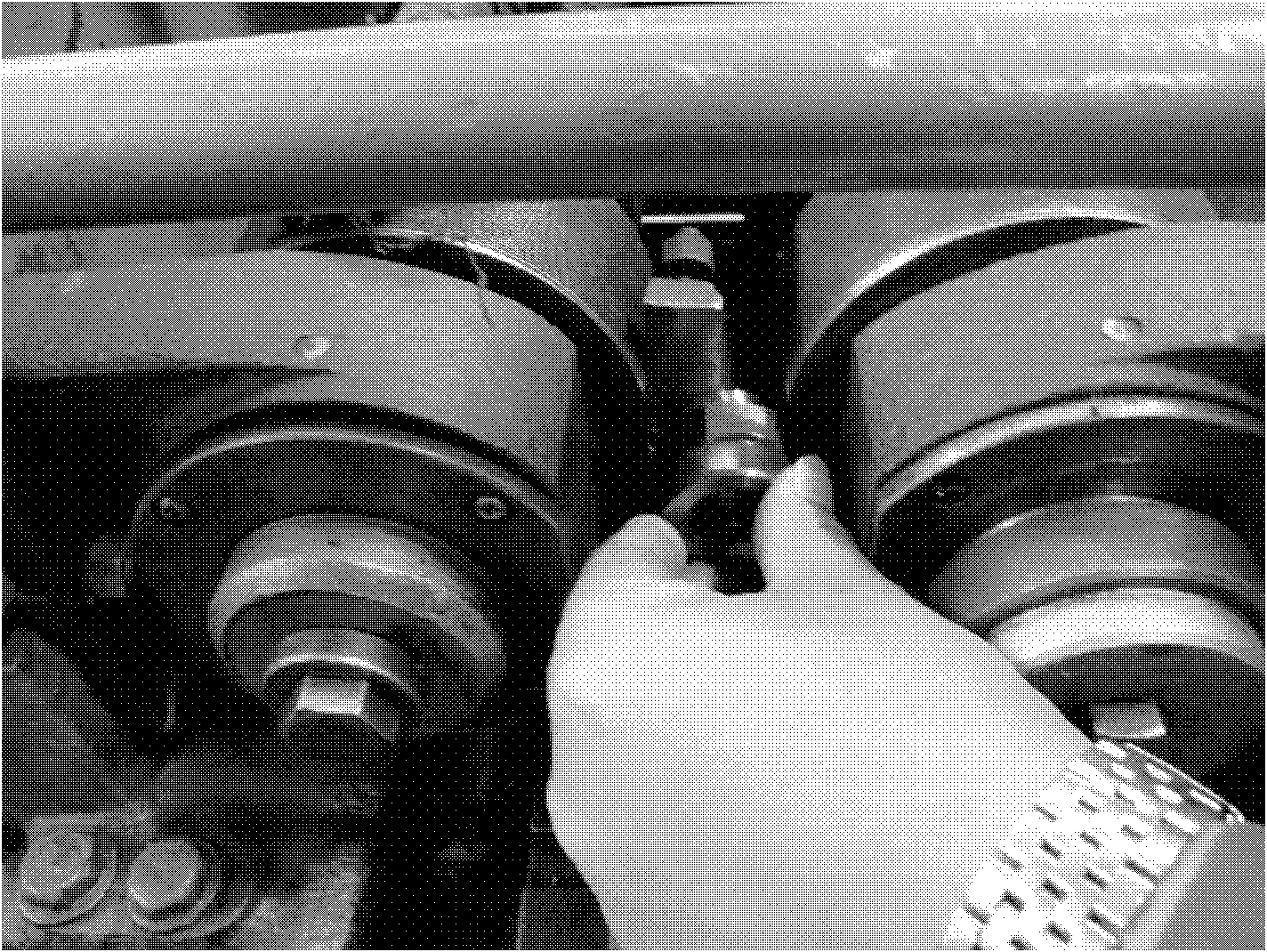

[0023] 1) Process the active thread rolling wheel 2 and the driven thread rolling wheel 1 used to process the required plane; prepare the positioning block 4 that meets the processing requirements; use the active thread rolling wheel 2 and the driven thread rolling wheel 1 to process and process the required plane, which means that the driving thread rolling wheel 2 and the driven thread rolling wheel 1 are processed by a surface grinder to grind a plane that matches the axial size of the extrusion head, which is easy to operate during extrusion , to prevent threads from being formed on the flattened surface, and the dimension is more stable after flattening.

[0024] 2) According to the axial dimension of the squeezed head of the hexagonal sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com