Advanced water-stopping isolation structure of later poured band for basement

A technology of isolating structures and post-pouring belts, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve problems such as high precipitation costs, waste of on-site work sites, unfavorable construction site safety production and civilized construction management, etc. Achieve the effect of increasing the working site, reducing the cost of precipitation, and eliminating the hidden dangers of foundation pit safety management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

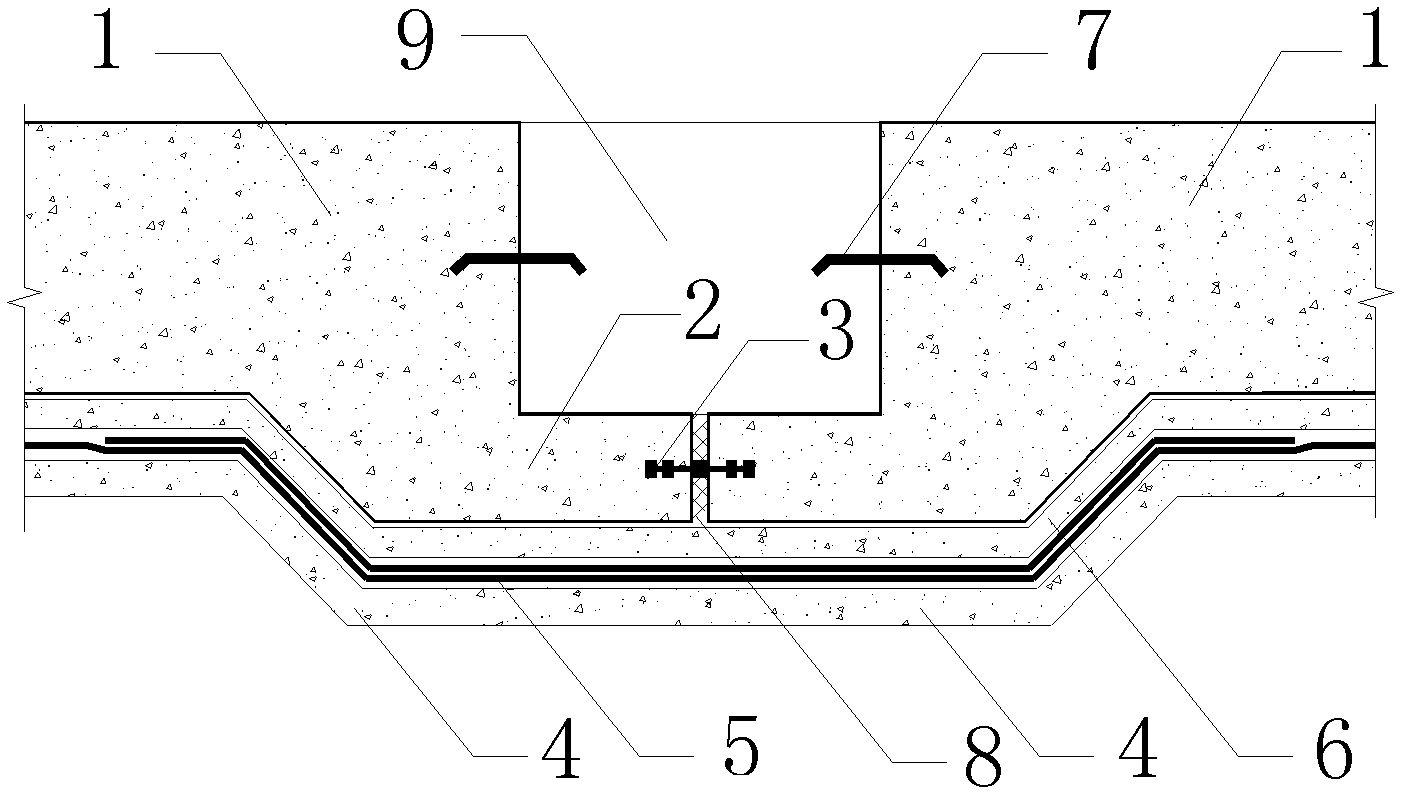

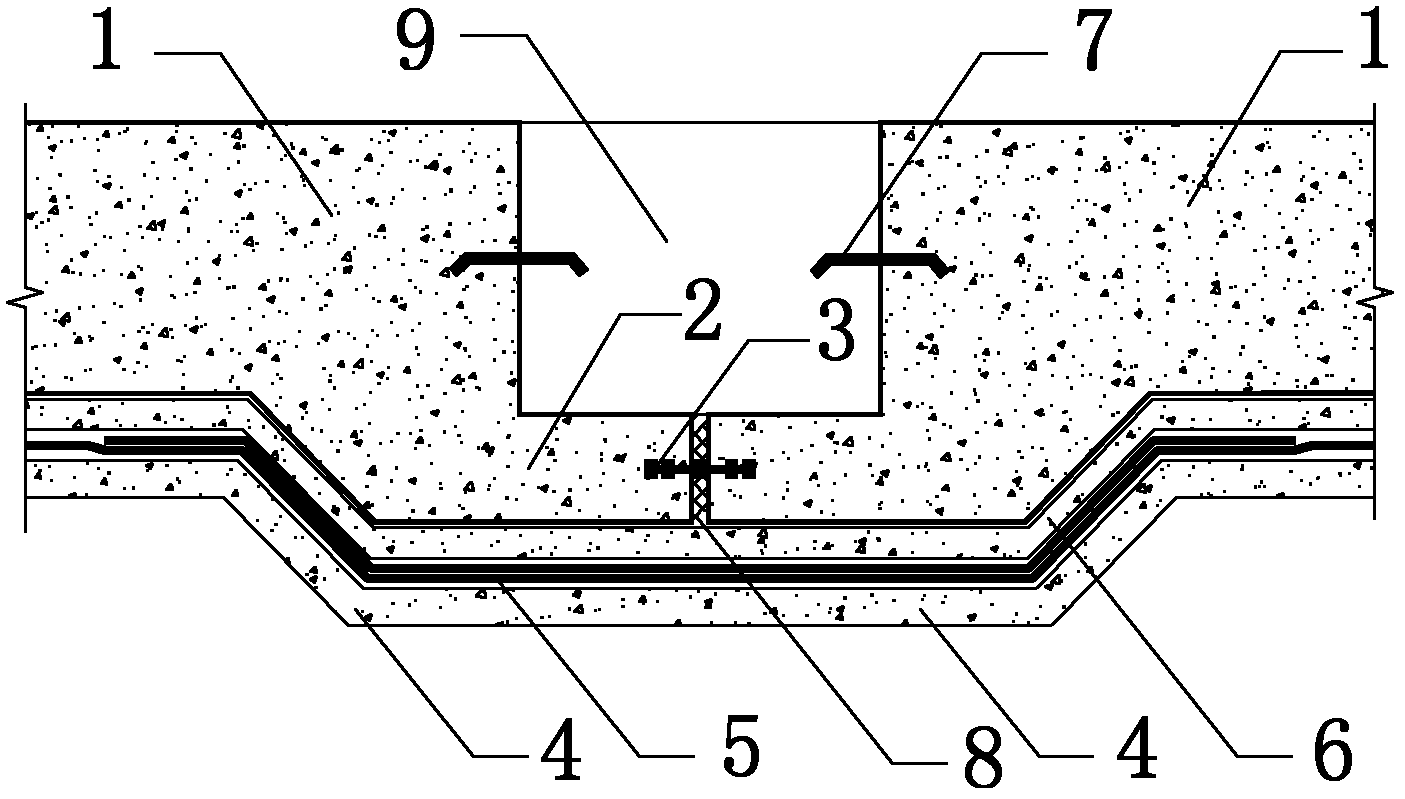

[0013] Such as figure 1 As shown, a basement post-casting belt advanced water-stop isolation structure includes pre-cast reinforced concrete slabs 1 on both sides of post-casting belt 9, and the pre-casting reinforced concrete slabs 1 on both sides are located below post-casting belt 9 Both are provided with extension flanges 2 , and rubber waterstops 3 with two ends inserted into the two extension flanges 2 are provided between the two extension flanges 2 . A filler 8 of soft material is filled between the two extension flanges 2 . Between the first-cast reinforced concrete slab 1 and the post-cast belt 9 on both sides, there is a U-shaped water-stop steel plate 7 whose two ends are respectively inserted into the first-cast reinforced concrete slab 1 and the post-cast belt 9 with openings facing downward. A waterproof layer 5 is lapped on the underside of the pre-cast reinforced concrete slab 1 and the extension flange 2 . A protective layer 6 is provided between the waterp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com