Ultrasonic transducer clamp for detecting concave R region of composite material structure

An ultrasonic transducer and composite material technology, which is applied in the analysis of materials, the use of sonic/ultrasonic/infrasonic waves for material analysis, instruments, etc. Stable position coupling and other issues to avoid missed detection and misjudgment, and improve the detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

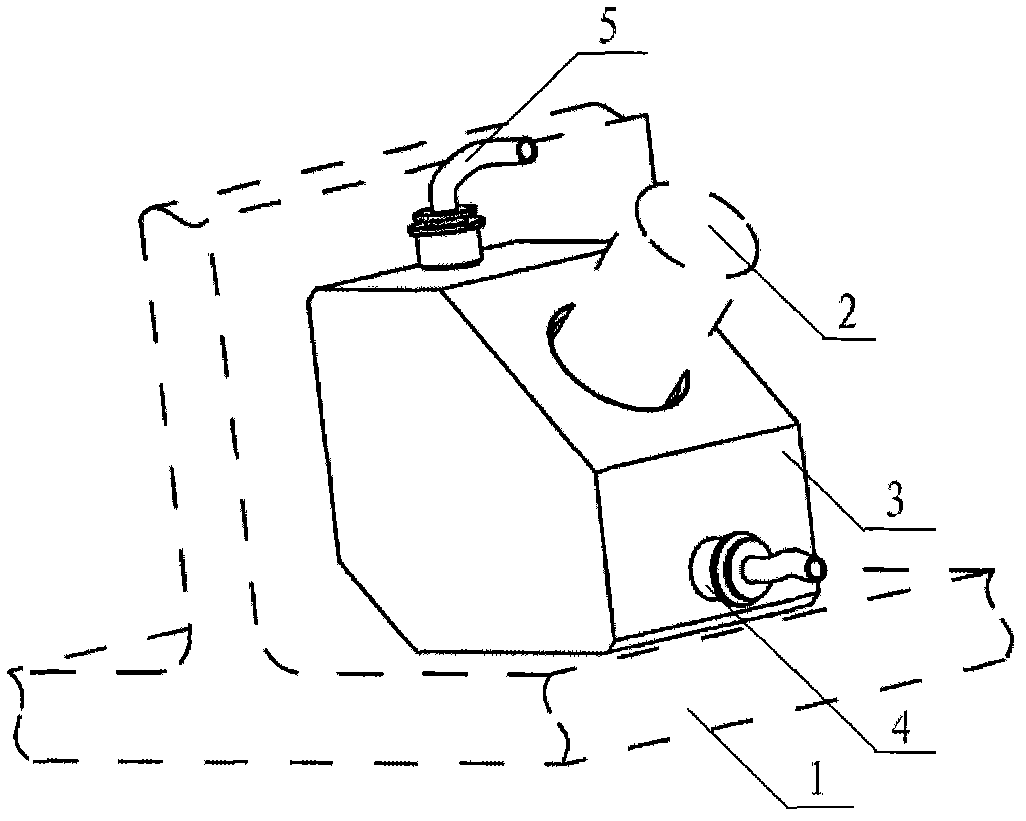

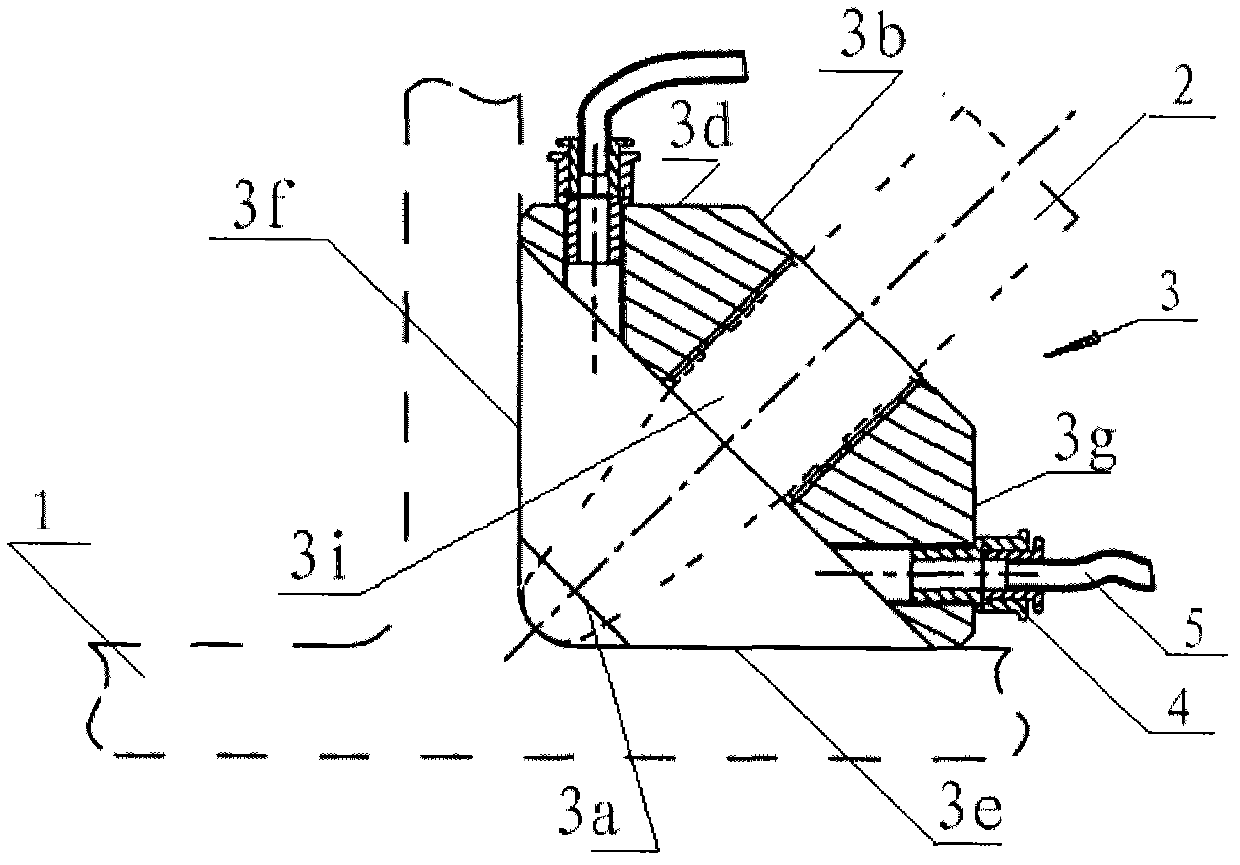

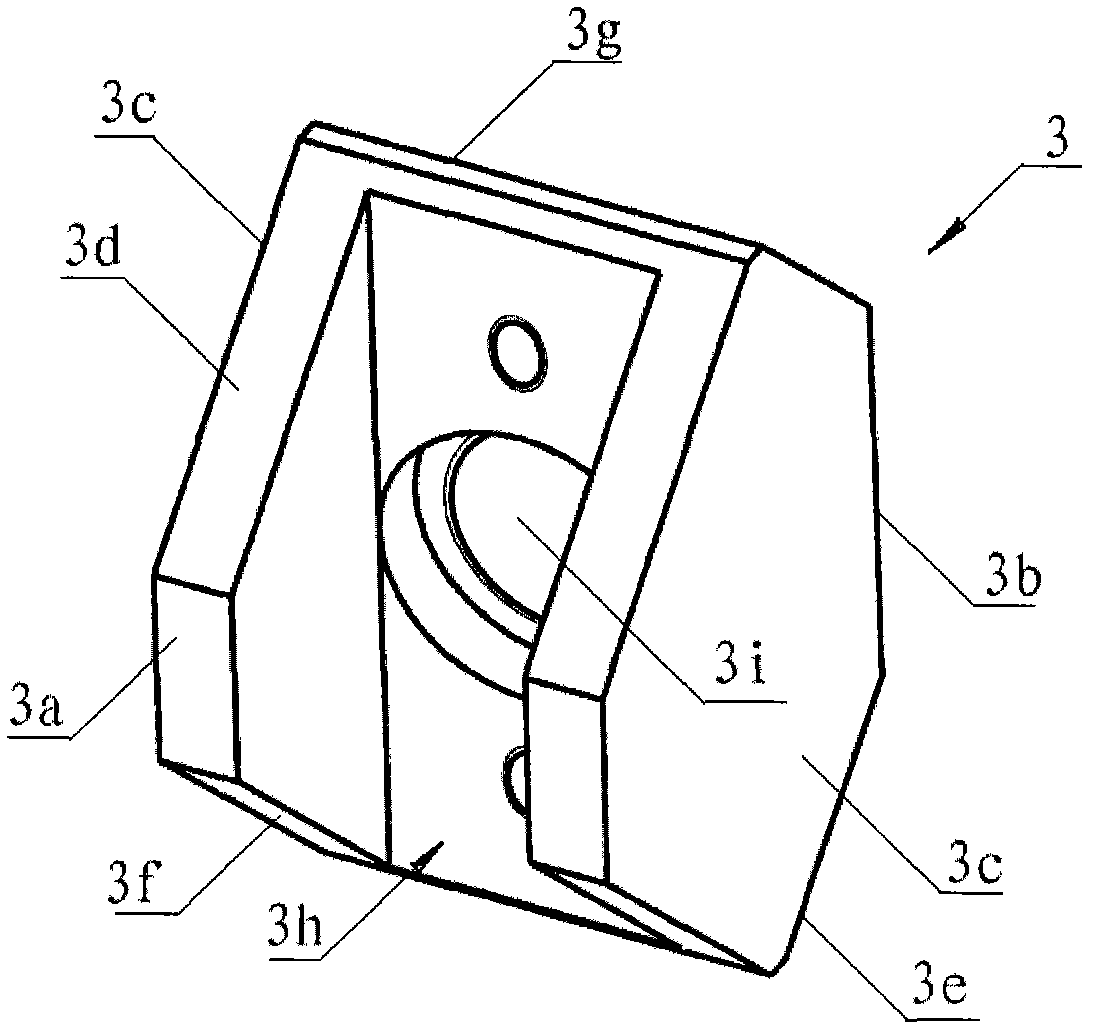

[0019] The included angle formed by the adjacent two sides of the concave R area of the tested composite material structure 1 is 90°, and the following ultrasonic transducer installation guide seat 3 is selected, the left surface 3f of the installation guide seat 3 and the bottom surface of the installation guide seat 3 The included angle of surface 3e is 90°. The ultrasonic instrument for composite materials is the FCC-B instrument produced by Beijing Aeronautical Manufacturing Engineering Research Institute. After a series of practical engineering applications on multiple batches and specifications of the actual composite material structure concave R area ranging from 3000mm to 5000mm in length and 1000mm to 3000mm in width, good actual detection results have been achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com