Automatic profiling detection system for ultrasonic water spraying penetration of curved generatrix revolving body composite material

A composite material and detection system technology, which is applied in the analysis of materials, the analysis of solids using sonic/ultrasonic/infrasonic waves, and the material analysis using sonic/ultrasonic/infrasonic waves, which can solve the problems of unintuitive results, low detection efficiency, and difficulty in guaranteeing , to achieve the effect of stable ultrasonic detection signal, high detection efficiency and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

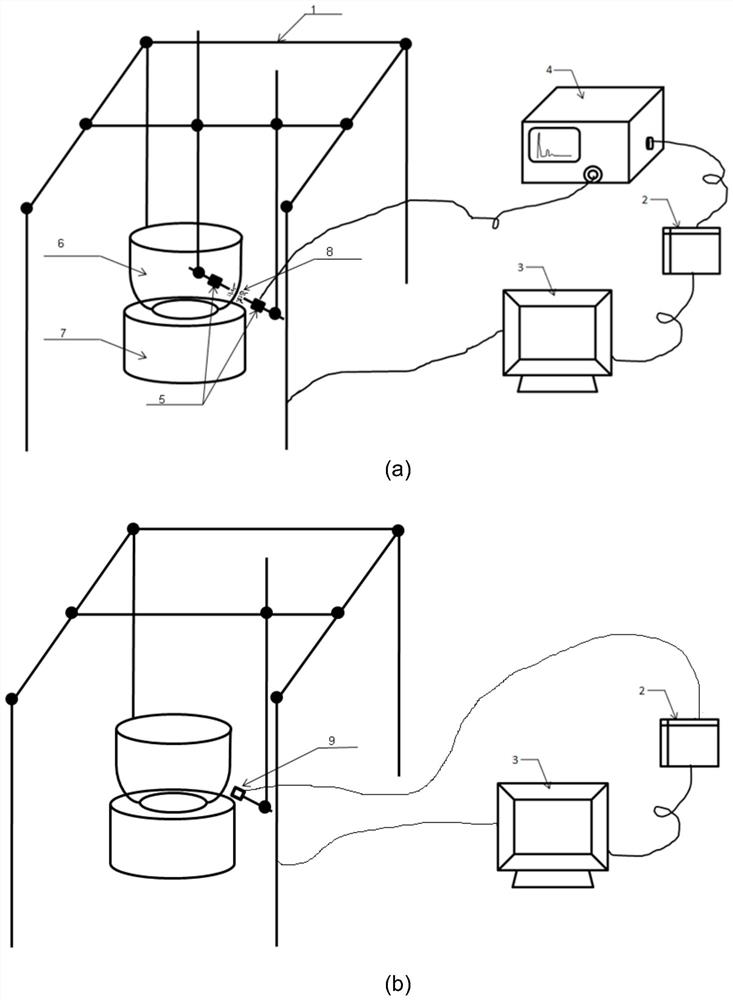

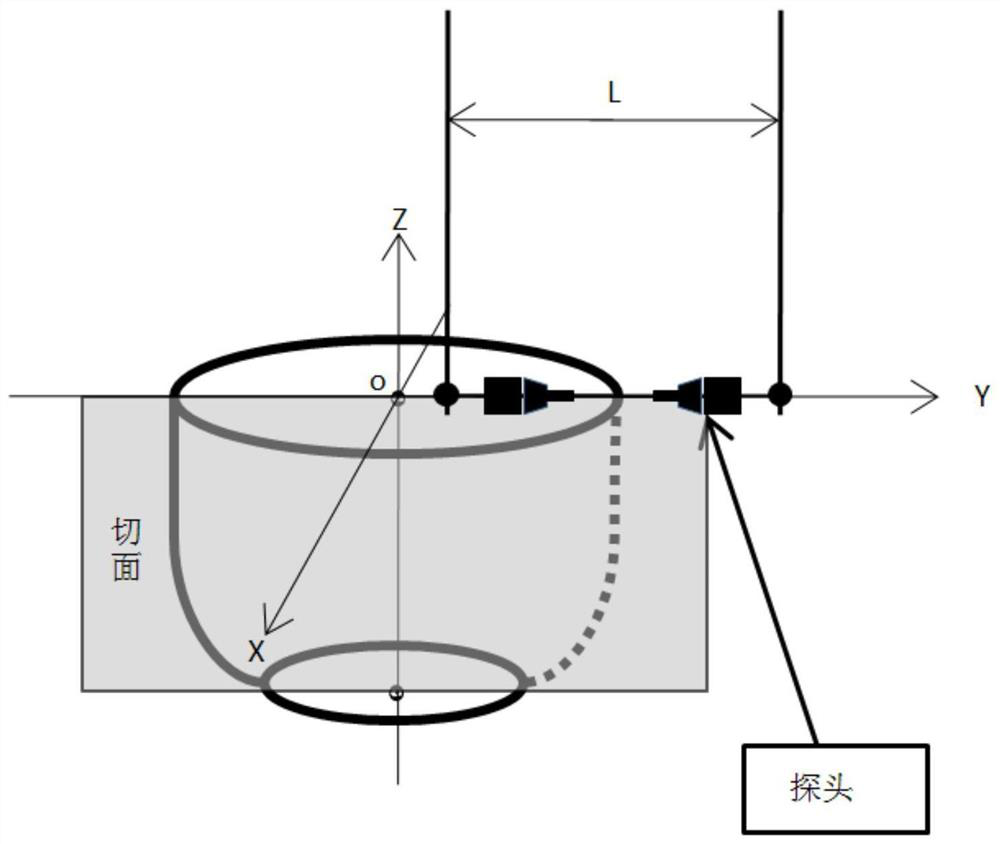

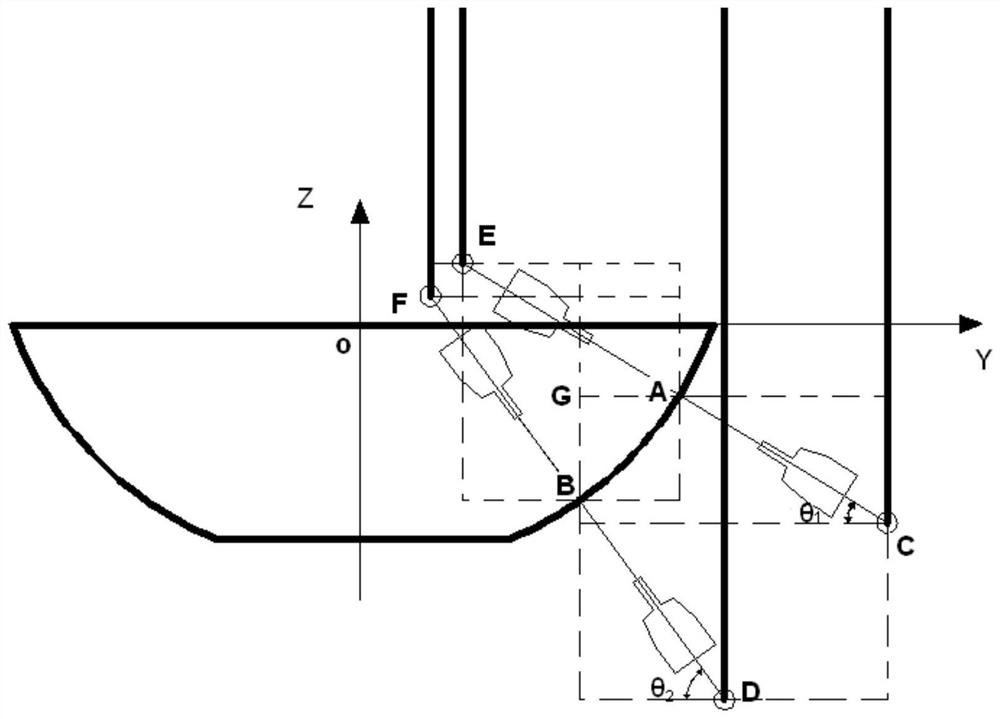

[0125] This embodiment proposes a method for ultrasonic water jet penetration automatic profiling detection of curved generatrix rotary structure composite materials, which includes the following devices, including: 8-axis motion control system 1, data acquisition card 2, industrial computer 3, ultrasonic Flaw detector 4, probe 5, curved generatrix rotary composite material 6, turntable 7, water circulation system 8 and laser range finder 9.

[0126] Specifically:

[0127] 8-axis motion control system 1: such as Figure 4 The gantry structure is shown, and the 8 axes include X axis, Y1 axis, Y2 axis, Z1 axis, Z2 axis, A axis, B axis, and C axis;

[0128] Data acquisition card 2: collect the amplitude of the ultrasonic signal received by the probe from the ultrasonic flaw detector;

[0129] Industrial computer 3: Receive the amplitude of the ultrasonic signal sent by the data acquisition card, control the motion of the system and quickly obtain the position of the probe, comb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com