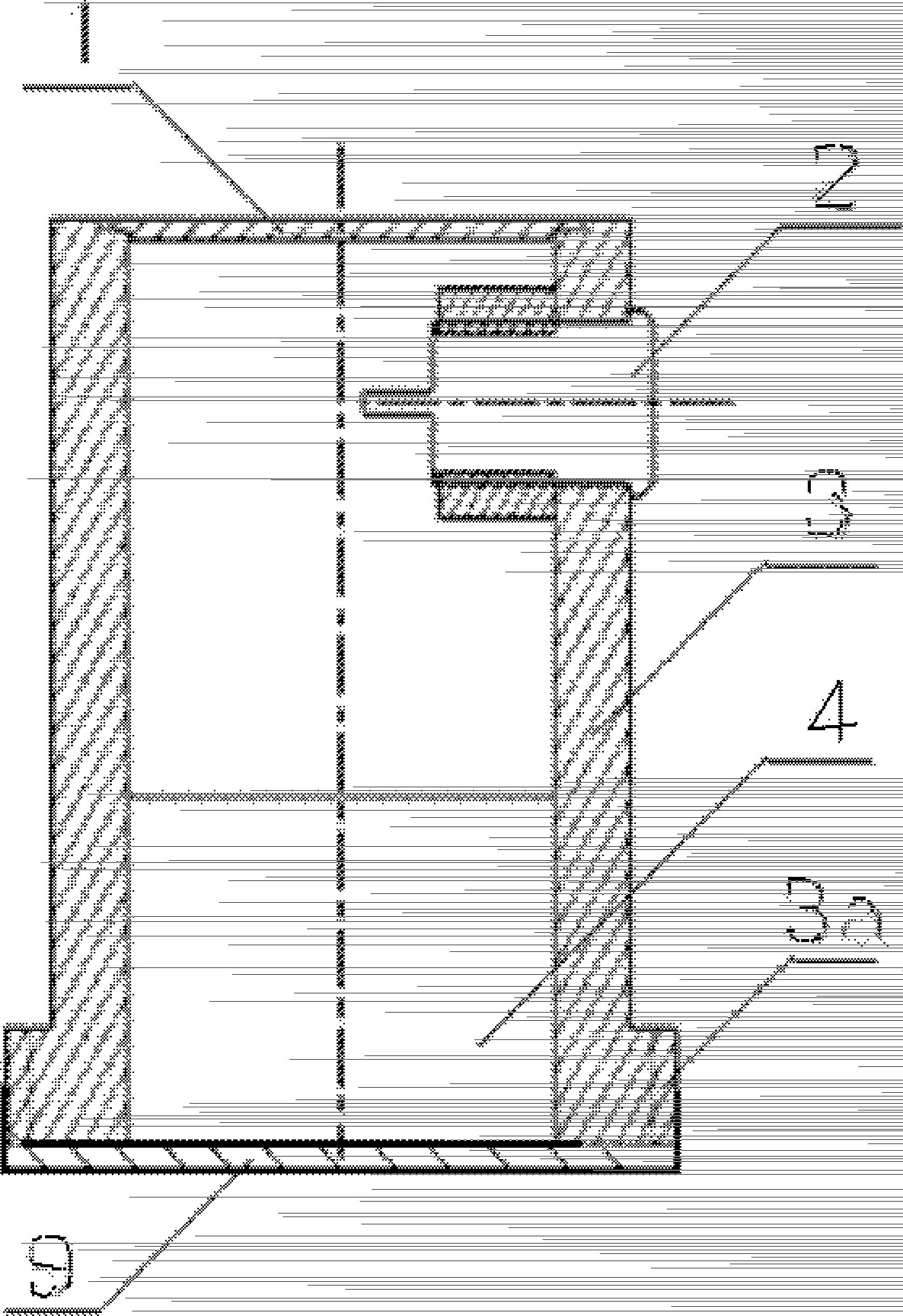

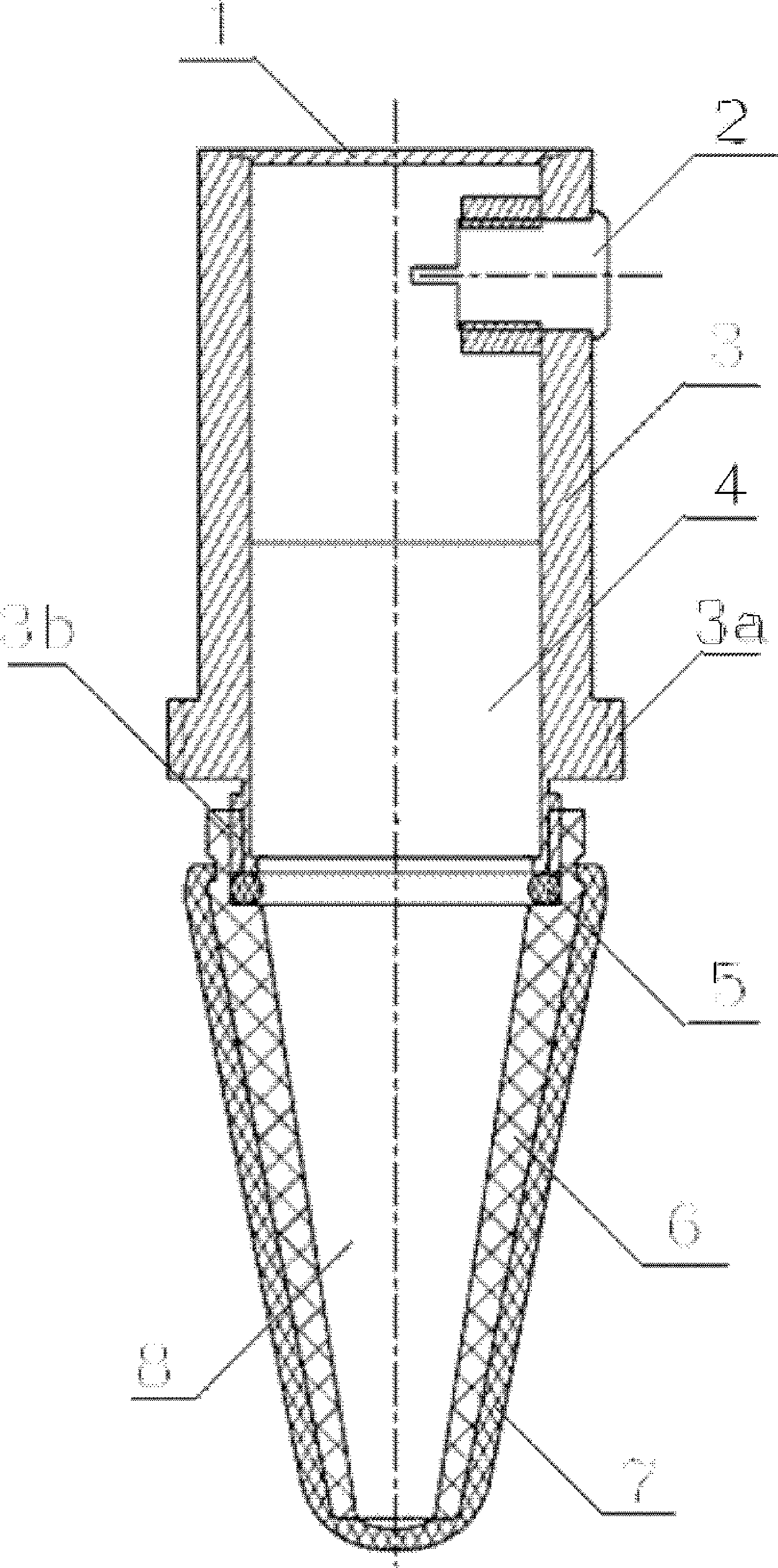

Ultrasonic probe for detecting R area of composite materials

A composite material, ultrasonic probe technology, applied in the direction of analyzing materials, using sonic/ultrasonic/infrasonic waves for material analysis, measuring devices, etc. Achieve the effect of avoiding missed detection and misjudgment and improving the detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1, the water bag 6 is made of plexiglass, the thickness of the water bag cover 7 is 0.2 mm, and the liquid in the inner cavity of the water bag 6 is water. Embodiment 2, the water bag 6 is made of aluminum alloy, the thickness of the water bag cover 7 is 0.3 mm, and the liquid in the inner cavity of the water bag 6 is water. Embodiment 3, the water bag 6 is made of polystyrene plastic, the thickness of the water bag cover 7 is 0.5 mm, and the liquid in the inner cavity of the water bag 6 is engine oil. The above-mentioned ultrasonic probe is used in conjunction with the ultrasonic probe fixture for testing the convex and concave R areas of the composite material structure through its external thread 3a. A series of practical engineering applications have been carried out in the R area of the material structure, and good actual detection results have been achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com