Insulator end clamp

A technology of insulators and fixtures, applied to overhead lines/cable equipment, etc., can solve problems such as difficulty, trouble, and difficulty in finding a fixed point on the wire side, and achieve the effects of preventing the expansion of accidents, wide application range, and simple and convenient construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

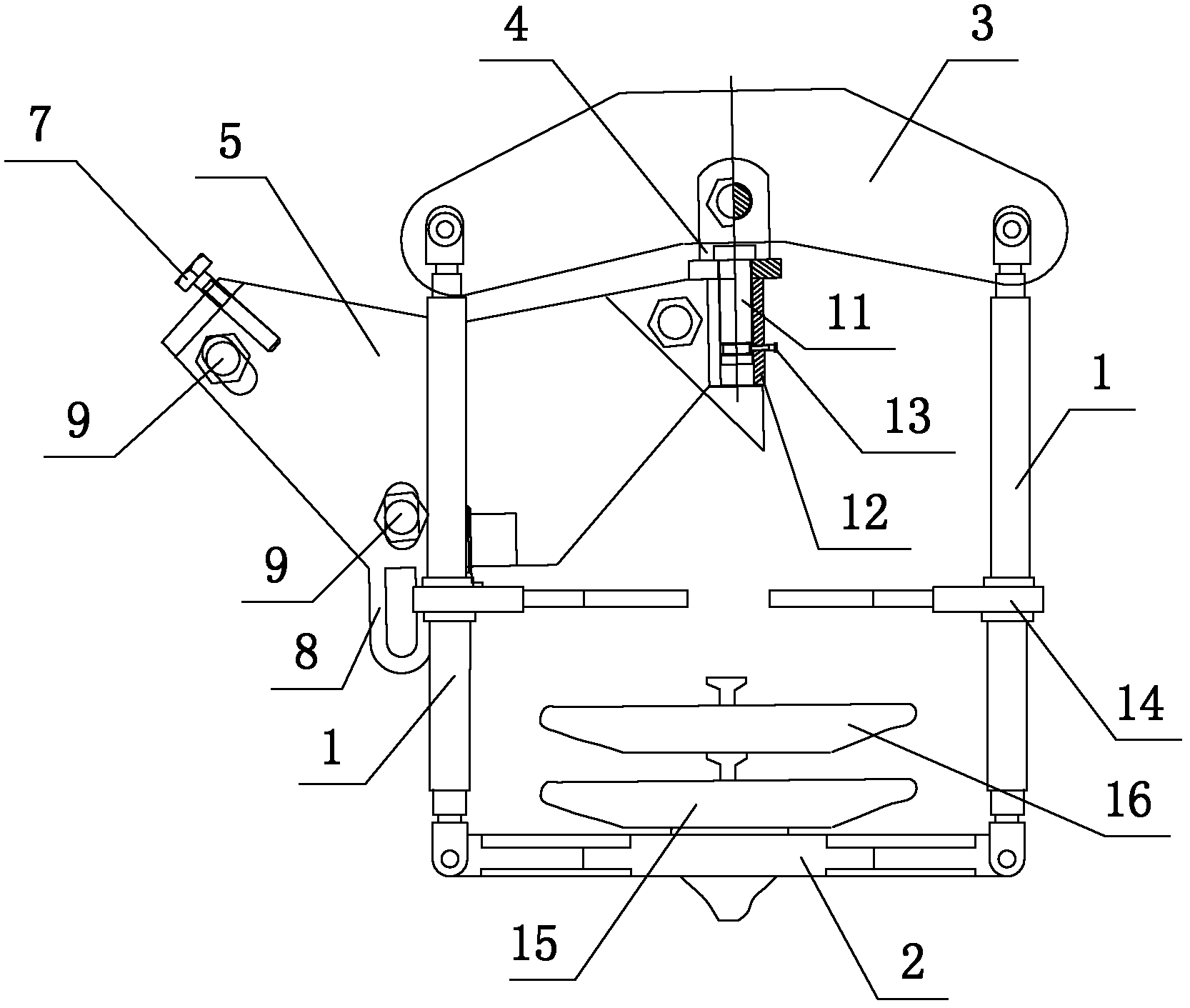

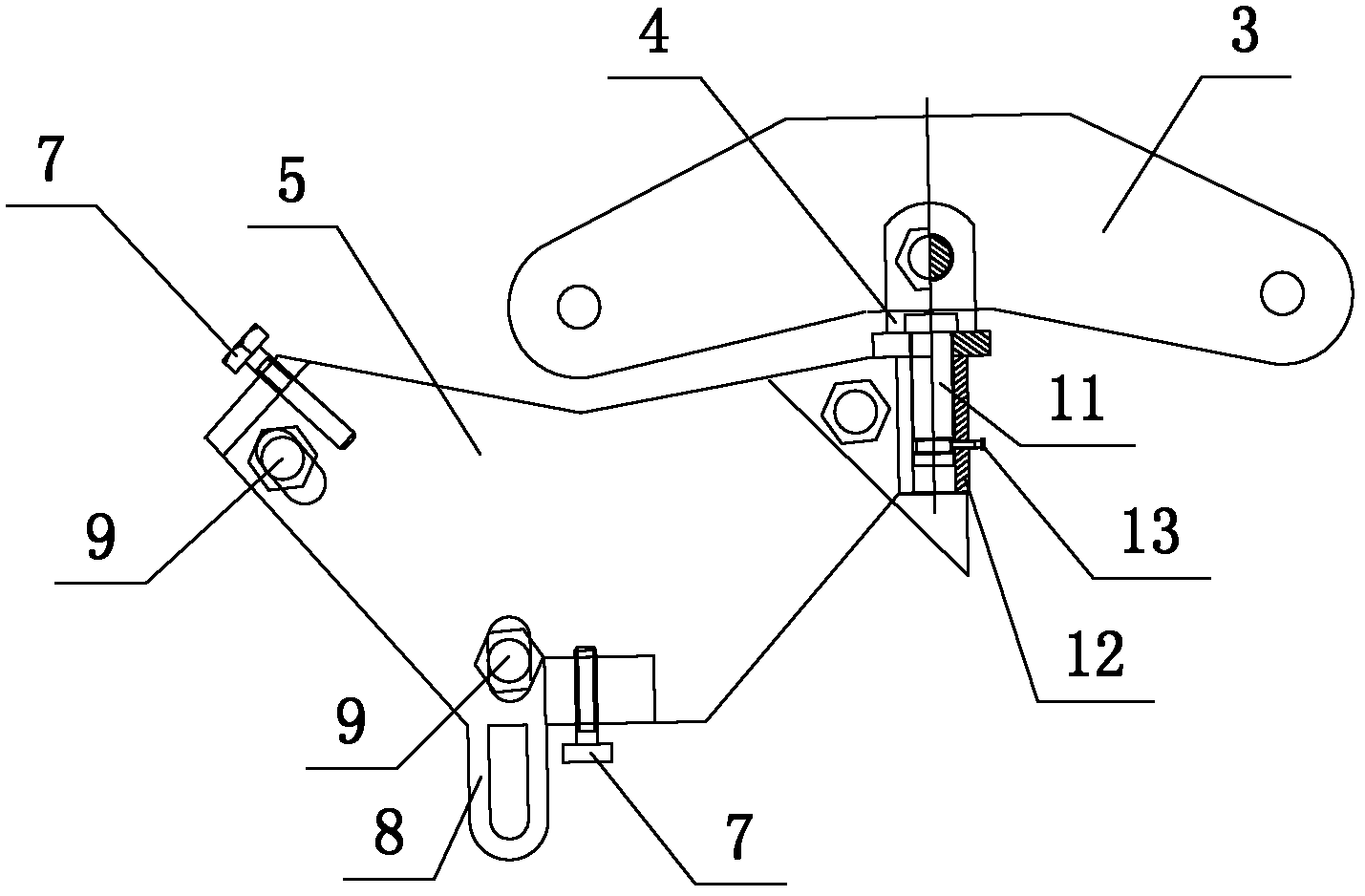

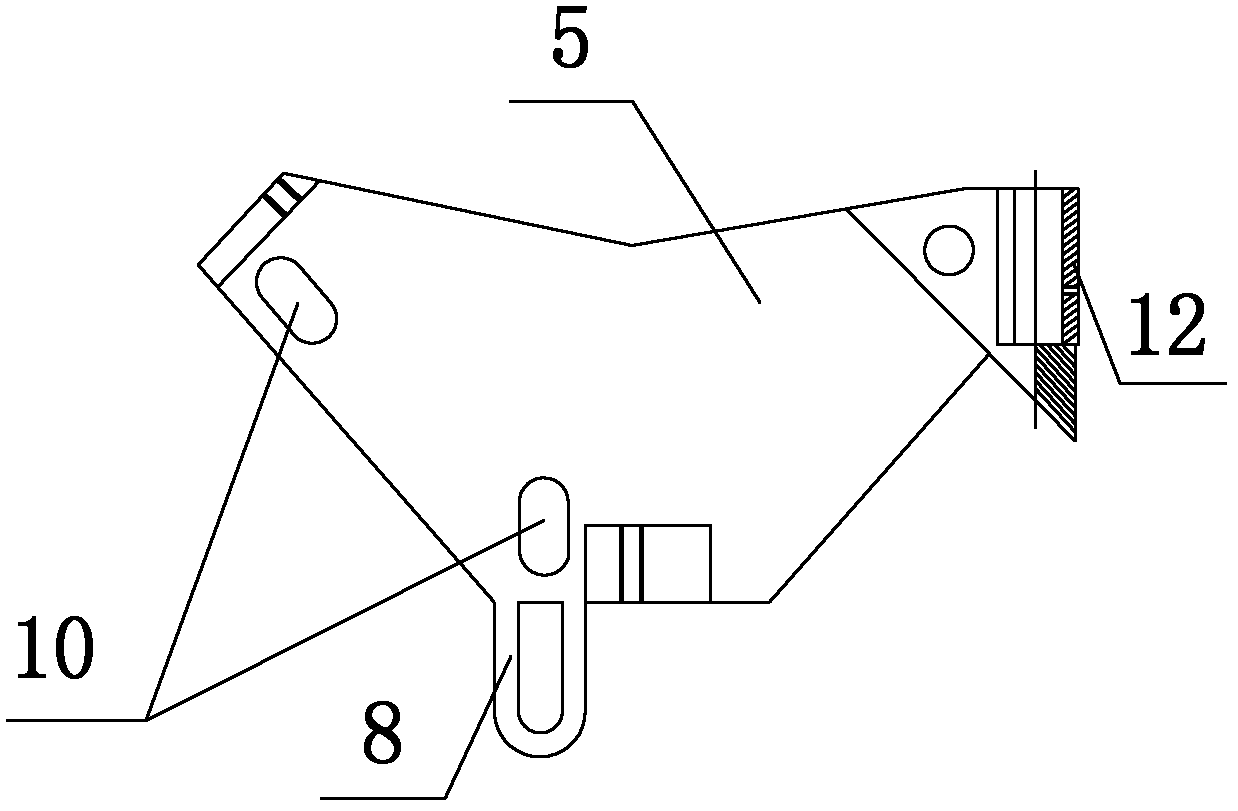

[0020] Such as Figure 1 to Figure 4 As shown, an insulator end clamp includes a clamp screw 1 with a clamp wire tightener 14, a clamp head 2 connected to one end of the clamp screw 1, and a hanger connected to the other end of the clamp screw 1. plate 3. A swivel head 4 is provided on the side of the hanging plate 3 facing the jig head 2, and a fixing device for fixing the triangular connecting plate on the wire is connected to the swivel head 4. The fixing device is composed of clamping plate 5 and cover plate 6 fastened to form a set of clamping bodies for clamping the triangular joint plate. The clamping plate 5 and the cover plate 6 are fixedly fastened together mainly by bolts 9, thereby clamping the triangular connecting plate on the wire. Therefore, both the clamping plate 5 and the cover plate 6 are provided with bolt holes 10 , and the bolt holes 10 are designed to be elongated, which is convenient for adjusting the relative position between the clamping plate 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com