Movable clamping plate structure

A mobile and clamping technology, which is applied in aircraft assembly, aircraft parts, ground installations, etc., can solve the problems of large workshop space occupied by storage, high cost of pallets, and potential safety hazards in lifting, so as to achieve economical manufacturing and universal applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

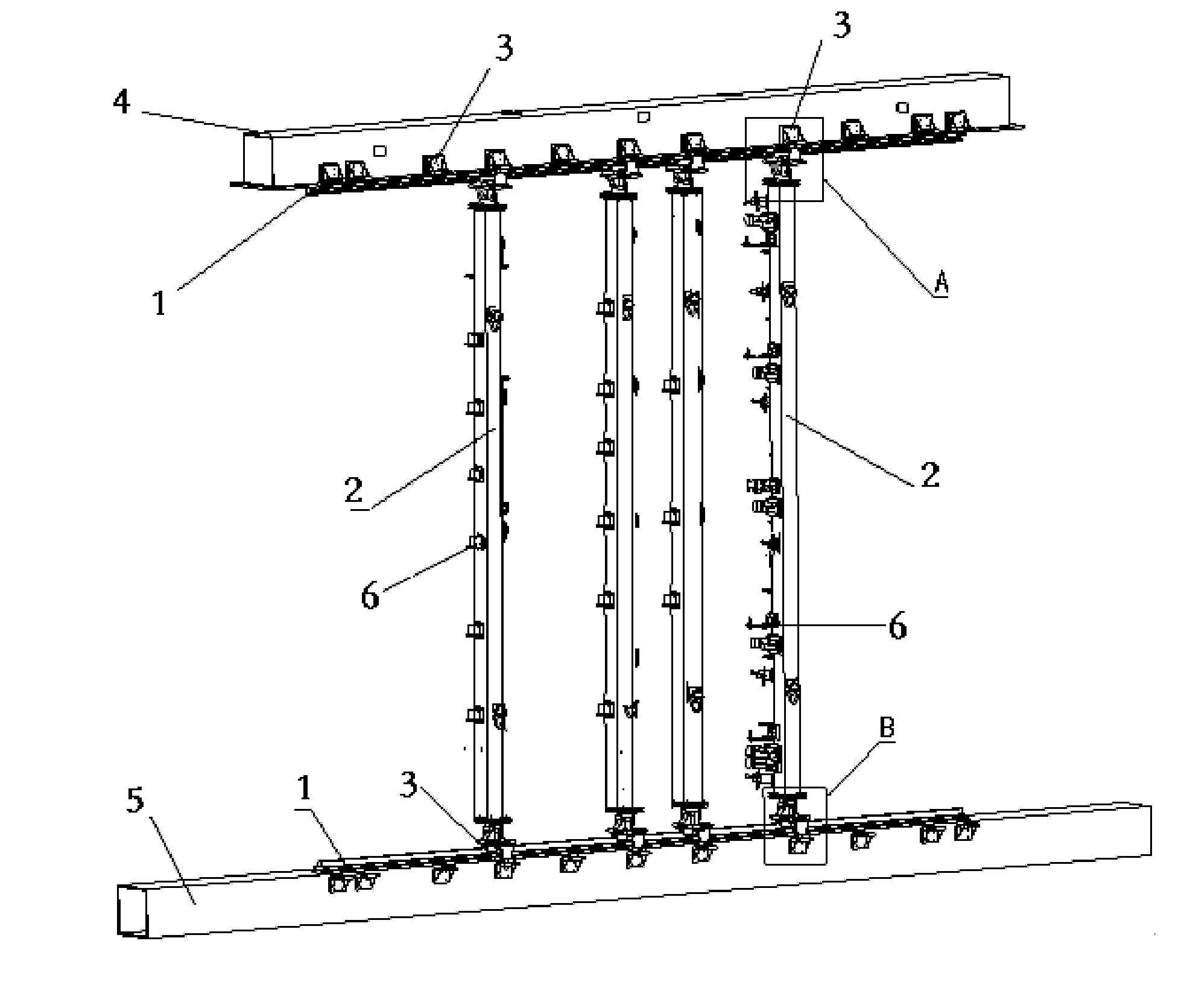

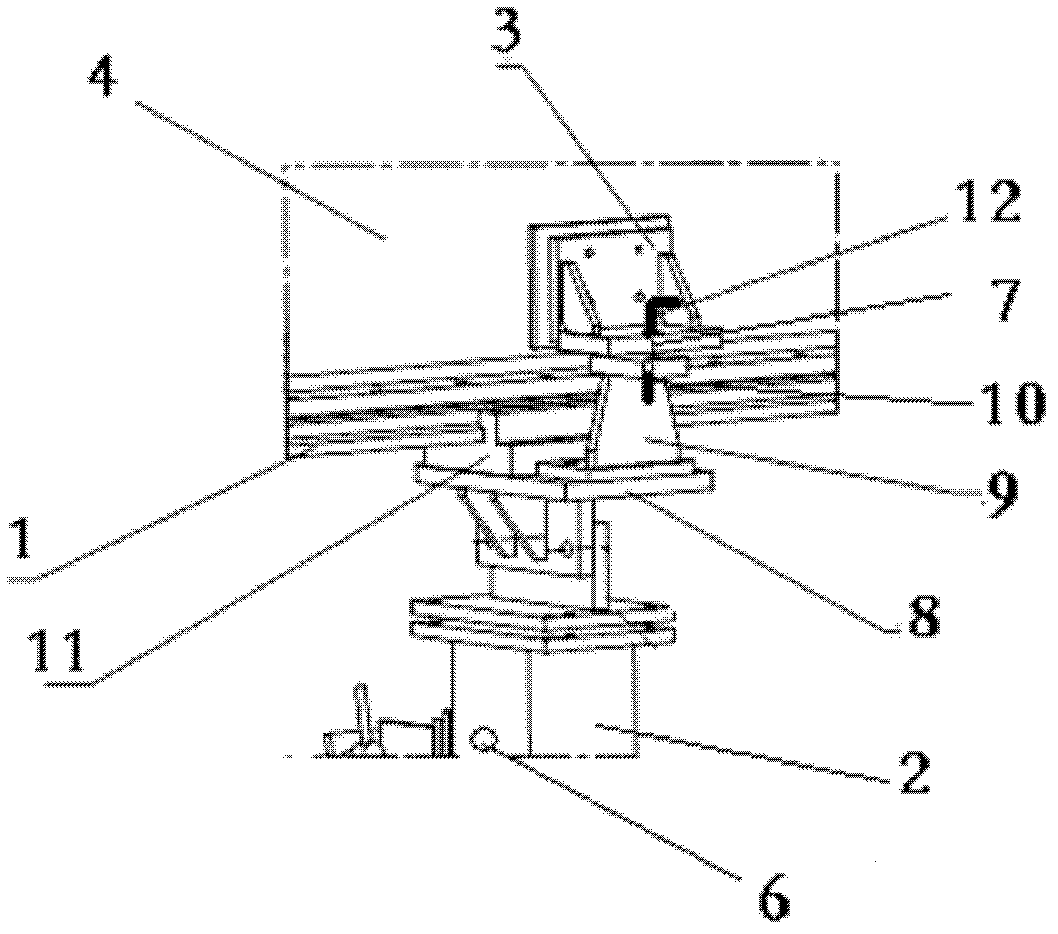

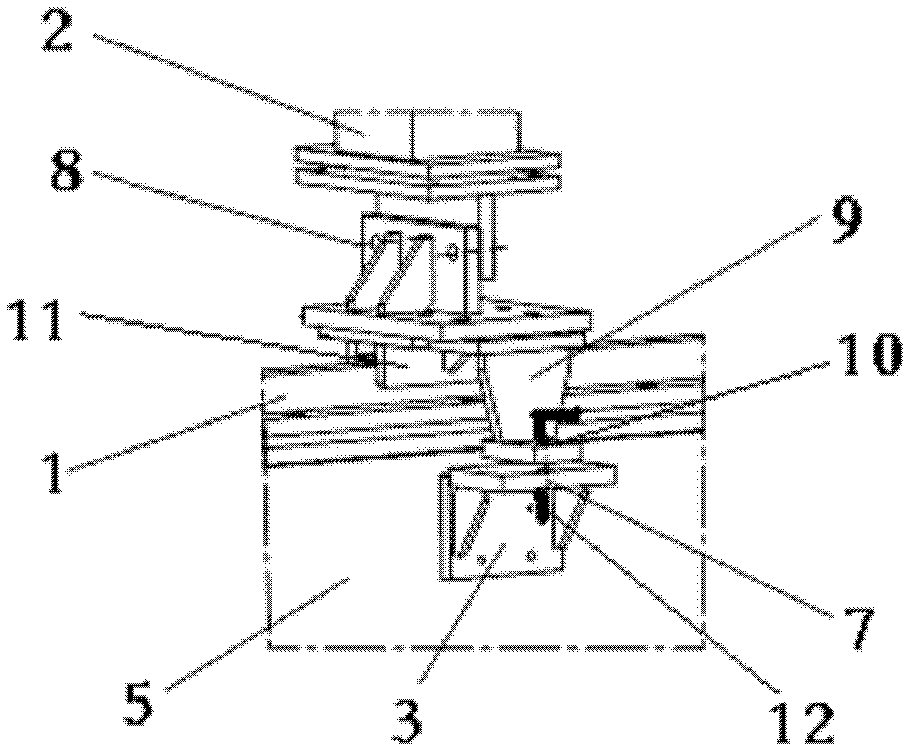

[0013] Referring to the accompanying drawings, a pallet structure that moves along the track, the mounting base of the pallet structure includes a set of corresponding upper beams 4 and lower beams 5 on a longitudinal three-dimensional surface, and the upper beam 4 and the lower beam 5 The relative inner side is respectively provided with rails 1, and the clamp body 2 is a steel or wooden columnar body. , used to install various tooling positioning fixtures; both ends of the clamp body 2 are fixed with the slider 11 through the connector 8, and the slider 11 is embedded on the slide rail 1, so that the clamp body 2 can be easily realized on the slide through the slider. Sliding on the rail 1; in order to facilitate the work at different stations, a positioning structure is provided between the clamp body and the slide rail, and the positioning structure is composed of the station feet 3, the positioning plate 9 and the positioning pin 12, The positioning structure between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com