Shutter type air regulating fire grate

A louver-type, air-regulating technology, which is applied in the direction of grates, lighting and heating equipment, etc., can solve the problems of complex overall structure, small adjustment range, and poor air adjustment effect, and achieve simple overall structure, large air volume adjustment range, Action flexible and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

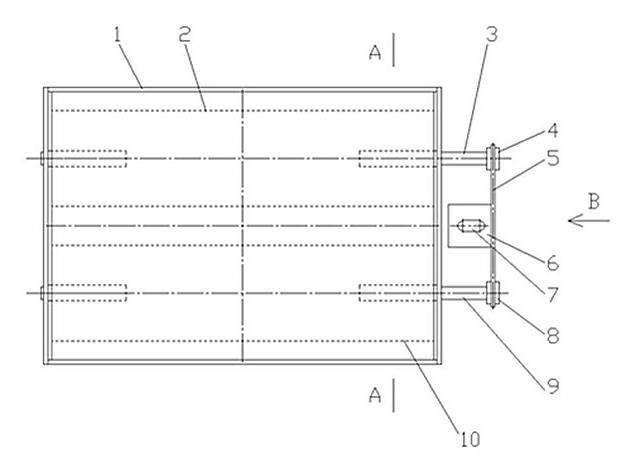

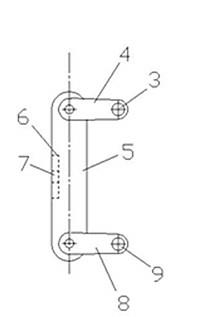

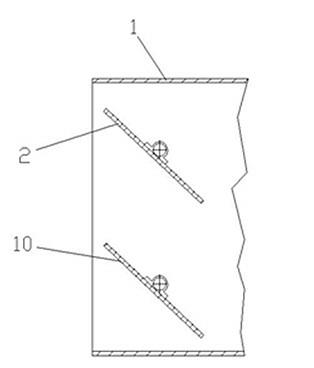

[0013] Such as figure 1 , 2 , Shown in 3, 4, and 5: 1 is an air supply duct, and its inner chamber section is square. The inner side of the air supply channel is connected with an air regulating plate through a rotating shaft, the air regulating plate includes an upper air regulating plate 2 and a lower air regulating plate 10, and an upper rotating shaft 3 is connected with the upper air regulating plate 2, and the upper air regulating plate 2 is supported by the upper rotating shaft 3 In the air supply channel 1, the outer end of the upper rotating shaft 3 is connected to the upper rotating plate 4, and the lower rotating shaft 9 is connected to the lower air adjusting plate 10, and the lower adjusting air plate 10 is supported in the air supply channel 1 through the lower rotating shaft 9. The lower rotating shaft 9 The outer end is connected with the lower rotating plate 8, and the upper air regulating plate 2 and the lower air regulating plate 10 are arranged parallel to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com