Patents

Literature

57results about How to "To achieve the purpose of measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coaxiality detecting and adjusting method for cartridge receiver of aero-engine

ActiveCN108036758AReduce stepsSimplify manual watch assemblyMeasurement devicesComputer programmingLeast squares

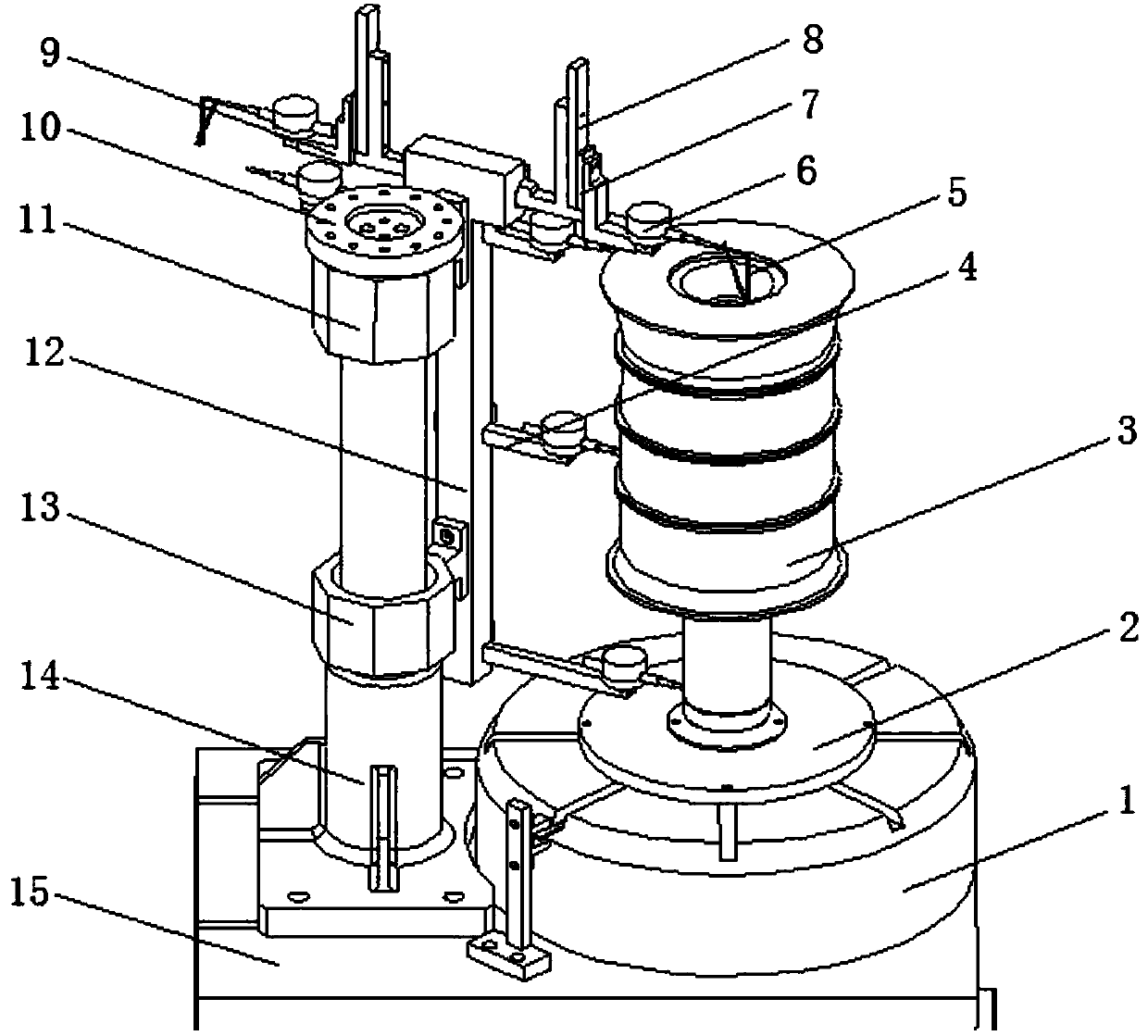

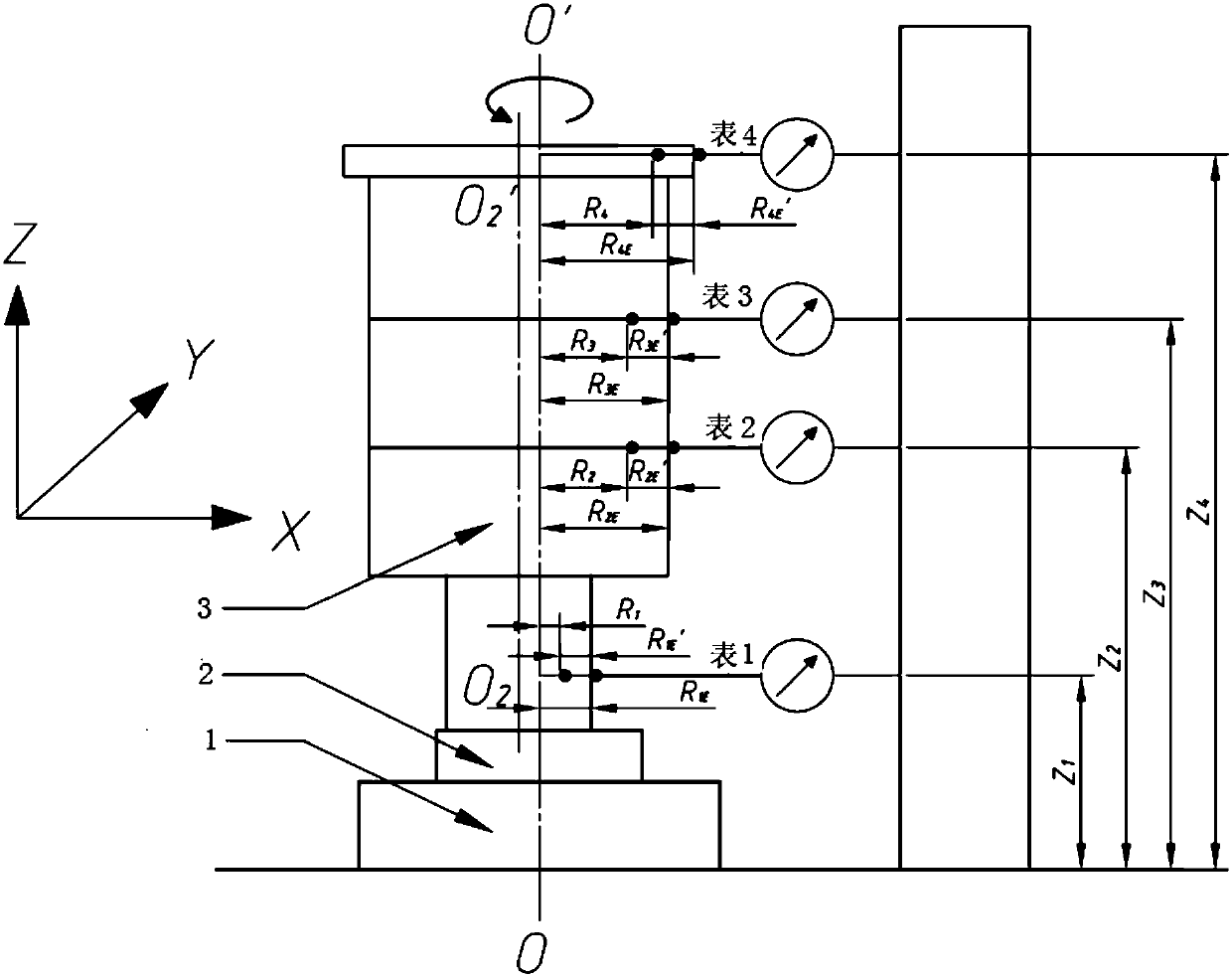

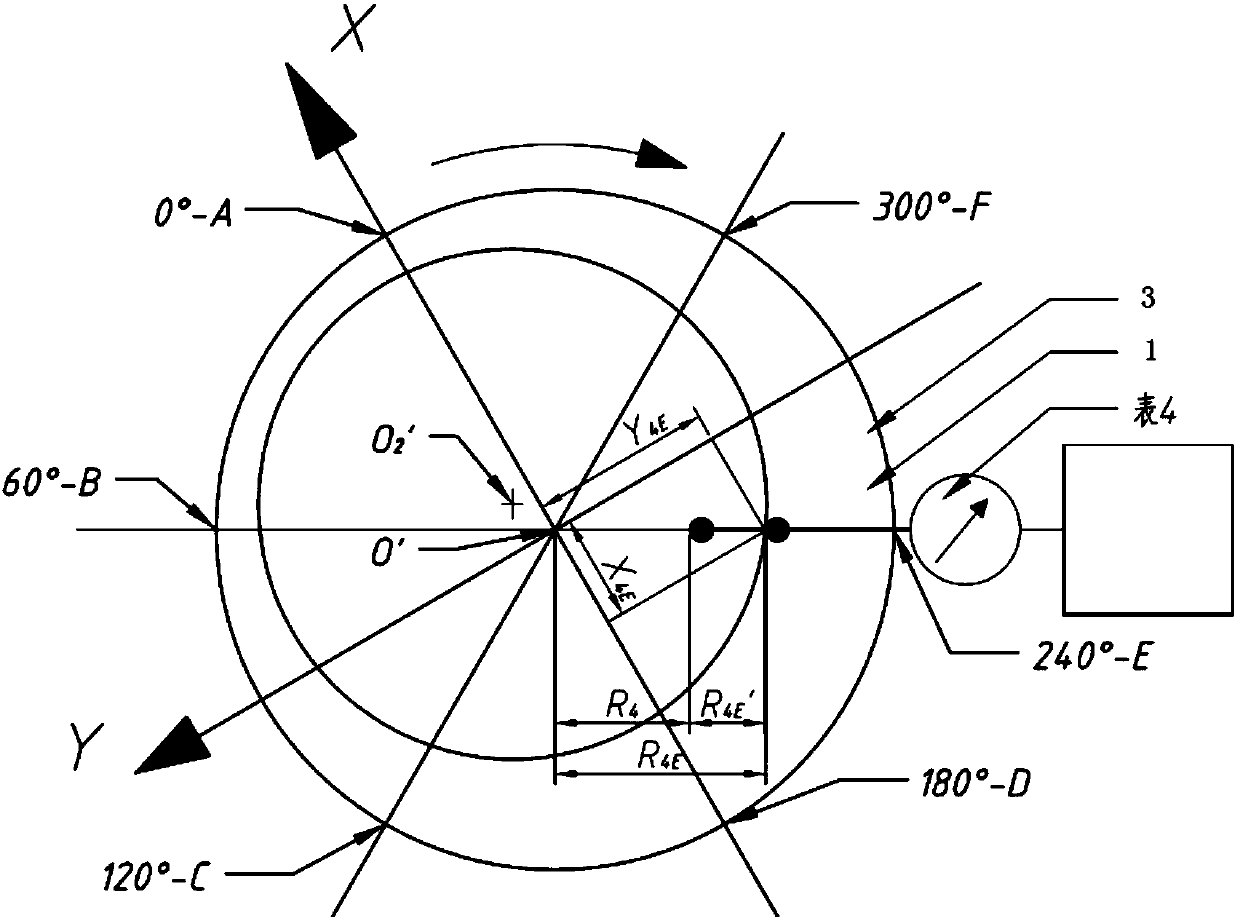

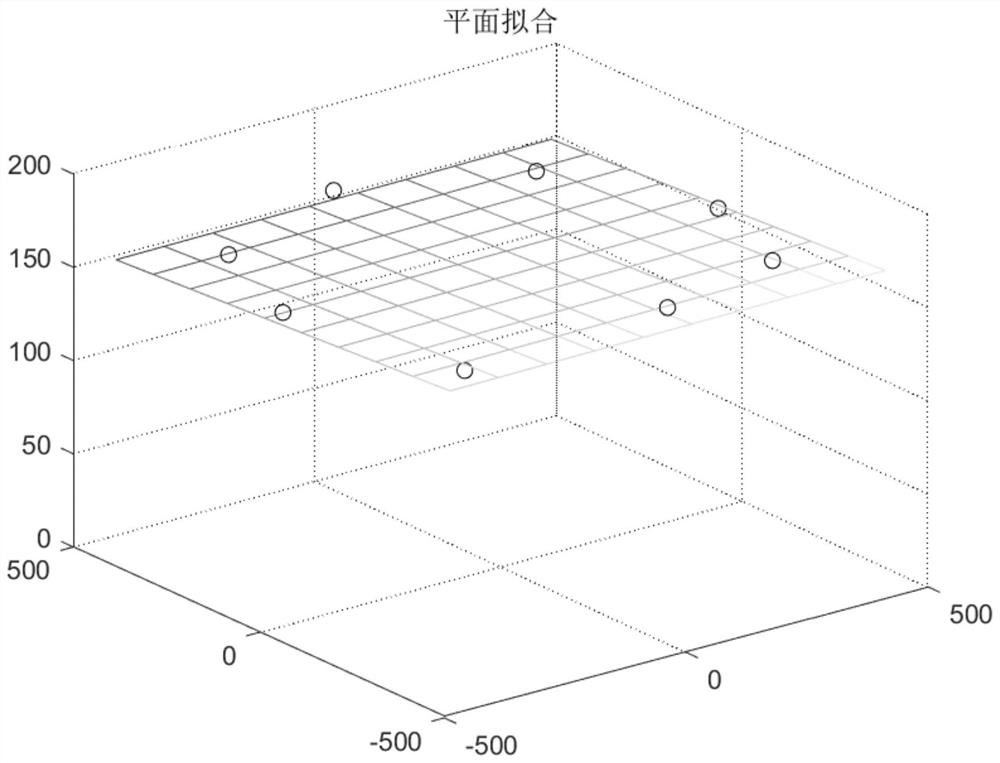

The invention discloses a coaxiality detecting and adjusting method for the cartridge receiver of an aero-engine and belongs to the field of manufacturing quality prediction and control. According tothe method, the position coordinates of all points of the cartridge receiver relative to the rotary center of a rotary table are measured. After that, the pose information of the cartridge receiver isobtained through least square method fitting and calculation. As a result, the coaxiality of all components on the cartridge receiver of the aero-engine can be measured and adjusted. Different from acommon rotary axis measuring method, the deviation and the inclination of the cartridge receiver are allowed, while only the detection limit cannot be exceeded. In this way, manually accurate clamping and adjusting steps are reduced, and the technical requirements on workers are reduced. The efficiency is improved. Meanwhile, based on the method, the manual meter installation is simplified, and ameter can be arranged for multiple times. The method is assisted by computer programming in the implementation process, wherein the manual reading, recording, calculation and other operations are reduced. The workload of workers is reduced, and the automation degree is improved. The measurement efficiency is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Snakelike motion detection and analysis system of high-speed-train bogie and method thereof

ActiveCN103712806AGuaranteed uptimeSuppress interferenceRailway vehicle testingBogieMotion generation

The invention discloses a snakelike motion detection and analysis system of a high-speed-train bogie and a method thereof. The system aims at analyzing the snakelike motion state of the high-speed-train bogie in different environments and different work conditions and reasons for generation of the snakelike motion and effects of the snakelike motion on operation security of the high-speed train. Bogie transverse and longitudinal acceleration signals are acquired through a transverse two-dimension acceleration sensor and a longitudinal two-dimension acceleration sensor, which are arranged on the bogie of the system and storage of characteristic data is performed through filtering of the signals by a real-time data acquisition controller and the analysis result and trend are transmitted to a train display terminal through a train transmission network. Therefore, long-term tracking and trend analysis of the bogie transverse and longitudinal data are realized and occurred faults of the bogie are monitored and alarmed in a real-time manner.

Owner:CRRC QINGDAO SIFANG CO LTD

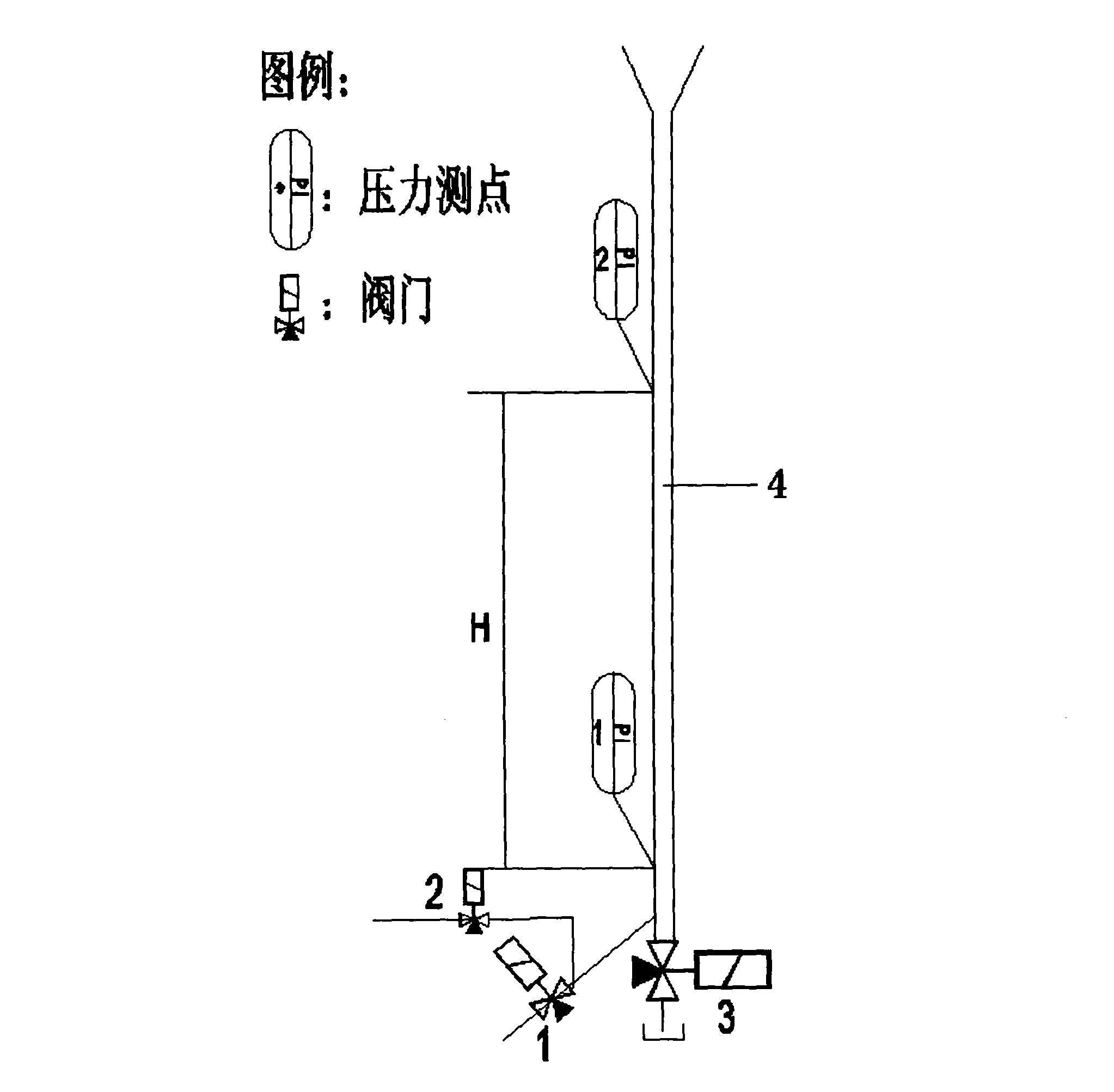

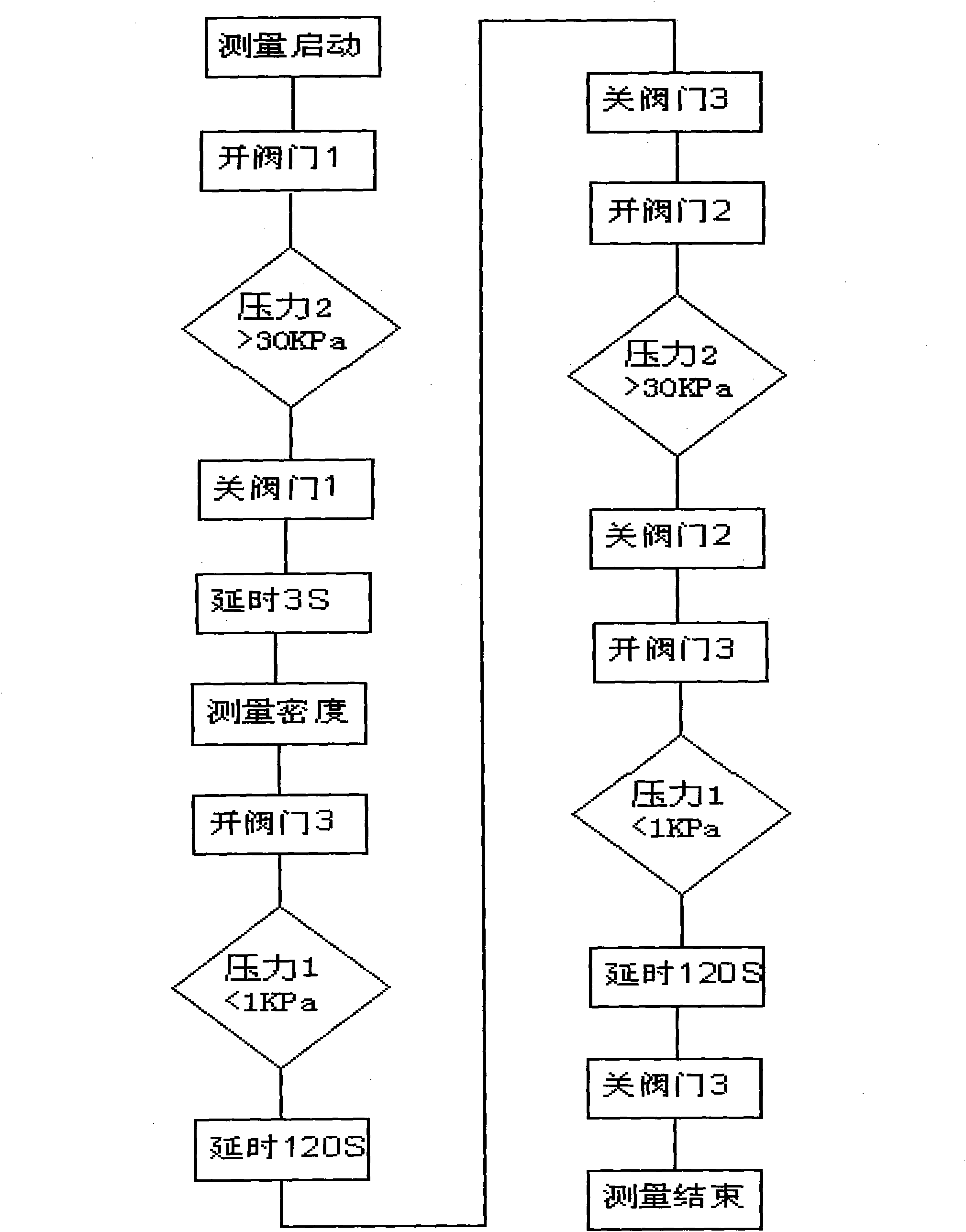

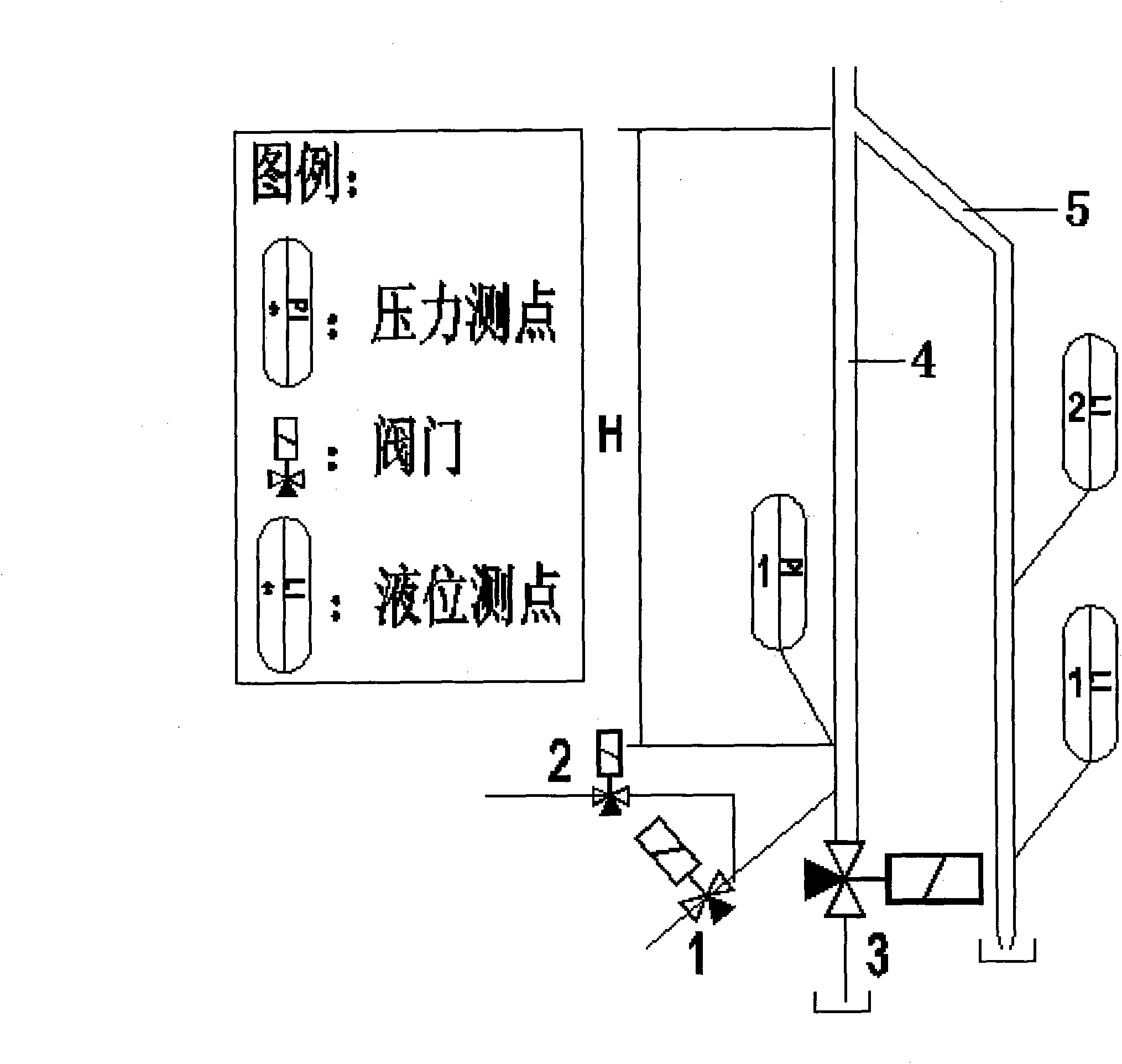

Sampling type size density measuring method

InactiveCN102384884ASolve problems that cannot be solved by online continuous measurementTo achieve the purpose of measurementSpecific gravity by measuring pressure differencesObservational errorSlurry

A sampling type density measuring method comprises the steps of preparing a size sample tube or a size sample container, sampling size to be tested into the size sample tube or the size sample container, measuring by adopting a pressure method or a weighing method and computing to obtain the density of the size after the size sample is static and stable, and evacuating the size sample in the size sample tube or the size sample container to wait for the next time of measurement. With the method, a small part of the size is adopted as a sample automatically and periodically, the volume of the sample is automatically measured by automatically weighing the mass of the sample (or the volume of the sample is fixed), and the density of the size is obtained by dividing the volume of the sample by the mass of the sample. Or when the method is used for measuring the pressure intensity of the sample, the fixed height of the sample is adopted, or the pressure difference of samples among different liquid columns is measured, so that the density can be measured by the relationship between the pressure intensity and the density. By adopting the method, the error links in the measurement are less, the accuracy of the measurement is high, and the measurement is conducted automatically and periodically.

Owner:杨玉娟

Method for measuring location degree of small hole

ActiveCN104006775ATo achieve the purpose of measurementTo achieve the purpose of small hole position measurementMeasurement devicesMeasurement deviceClassical mechanics

The invention relates to a method for measuring the location degree of a small hole. A projection coordinate meter is adopted as a measurement device, a standard part is used as the reference, a mechanical measurement head and an optical measurement head are verified and linked, a coordinate system is set up through the mechanical measurement head, the optical measurement head is used for measuring the position of the small hole, and the purpose of measuring the location degree of the small hole is achieved. The mechanical measurement head and the optical measurement head are matched to measure the small hole, measurement precision is high, and the overall measurement scheme is simple and reasonable, and easy to operate.

Owner:HARBIN DONGAN ENGINE GRP

Portable goods limit measurement instrument

InactiveCN104655049AThe implementation process is simpleAvoid cumbersomeUsing optical meansBody compartmentReal time display

The invention discloses a portable goods limit measurement instrument, which comprises a video camera, a mechanical support for supporting the video camera, and a handheld controller for adjusting the mobile position of the video camera; the mechanical support comprises a vertical sliding table and a horizontal sliding table, wherein the vertical sliding table is vertically arranged on the upper end of a main support, the horizontal sliding table can slide along the vertical sliding table, and the video camera can move along the horizontal sliding table; image information acquired by the video camera is transmitted to the handheld controller for displaying. A method of observing the edge contour of a train compartment projection through the video camera is adopted for measuring the space position of the camera in real time so as to measure the heights and widths of goods loaded in a compartment, and the scheme realization process is simple; the complexity of wired connection can be avoided in a wireless communication manner; a image of the video camera can be displayed in real time through the handheld controller, a reference datum line and real-time height and width information of observed goods can be marked on the display interface so as to realize the measurement purpose. The mechanical structure adopts a withdrawable structure, thus being convenient to carry.

Owner:SUZHOU R&D CENT OF NO 214 RES INST OF CHINA NORTH IND GRP

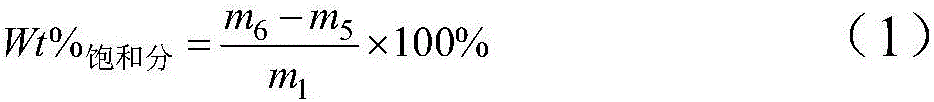

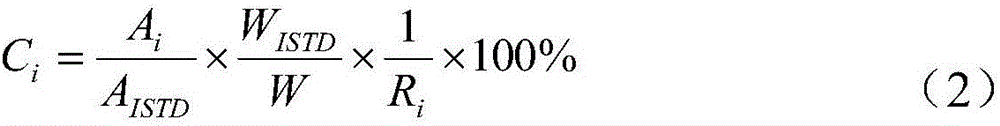

Method for determining content of saturates, wax and oil in rubber and rubber auxiliaries

The invention provides a method for determining content of saturates, wax and oil in rubber and rubber auxiliaries. The method comprises the steps as follows: a solution containing rubber or rubber auxiliary samples or a solution containing rubber or rubber auxiliary sample extracts is added to a chromatographic column, the solution sequentially passes through a clay adsorbent layer and a silica gel layer in the chromatographic column, the solution passing through the chromatographic column is collected, saturates are obtained after a solvent in the collected solution is removed, an internal standard substance is added to the obtained saturates, the mass percentage of each alkene is calculated through gas chromatography test, the wax content is calculated, the difference between the wax content and the saturate content is the content of oil in the sample, the extracts are obtained after removal of the solvent from extract solution obtained through extraction of rubber and rubber auxiliary samples. The saturates in rubber products and rubber auxiliaries can be separated and quantified under the condition of normal temperature and extremely small loading quantity with the method.

Owner:SINO LEGEND CHINA CHEM +1

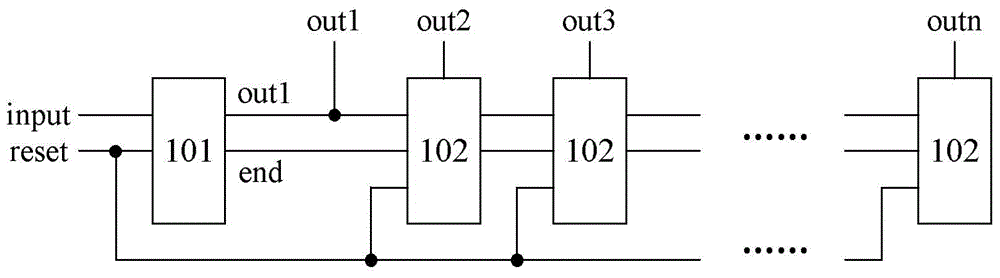

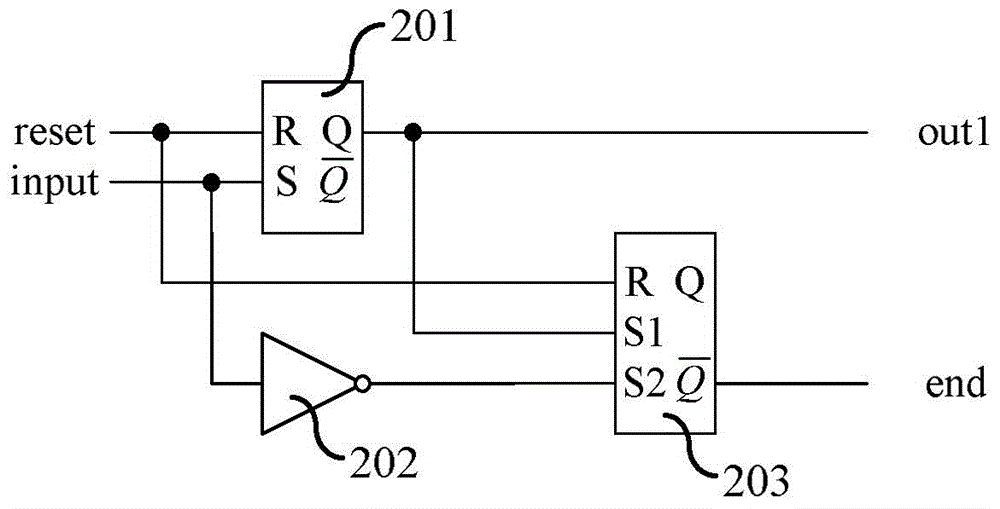

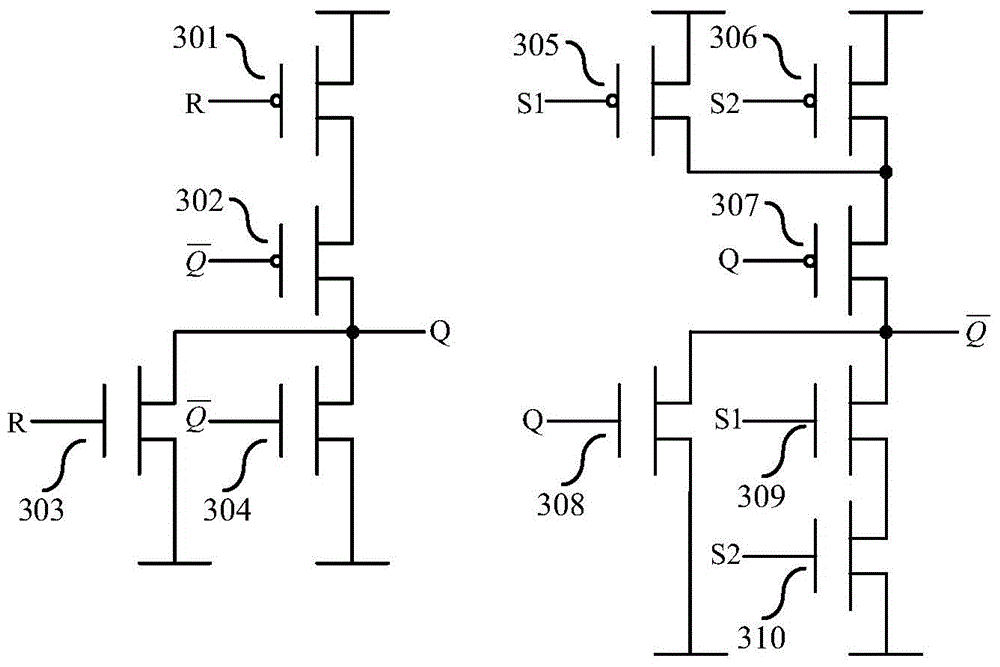

Circuit for measuring width of single-particle transient pulse

ActiveCN104808073AHigh measurement accuracyTo achieve the purpose of measurementPulse characteristics measurementsControl signalAccuracy and precision

The invention discloses a circuit for measuring width of a single-particle transient pulse. The circuit includes a control signal generation circuit and at least one grade of dual-delay comparison circuit, wherein the control signal generation circuit is provided with a reset input end, a single-particle pulse receiving end, a pulse start output end and a pulse end output end; each grade of dual-delay comparison circuit is provided with a reset input end, a first delay input end, a second delay input end, a first delay output end, a second delay output end and a comparison output end. The first delay input end in the first grade is connected with the pulse start output end while the second delay input end is connected with the pulse end output end, and from the second grade, the first delay input end in each grade is connected with the first delay output end of the previous grade while the second delay input end is connected with the second delay output end of the previous grade. The measuring circuit realized according to the invention can measure the high level pulse width of single-particle transient pulse, and is wide in measurement range and high in measurement accuracy.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Equipment and method for measuring material damping factor

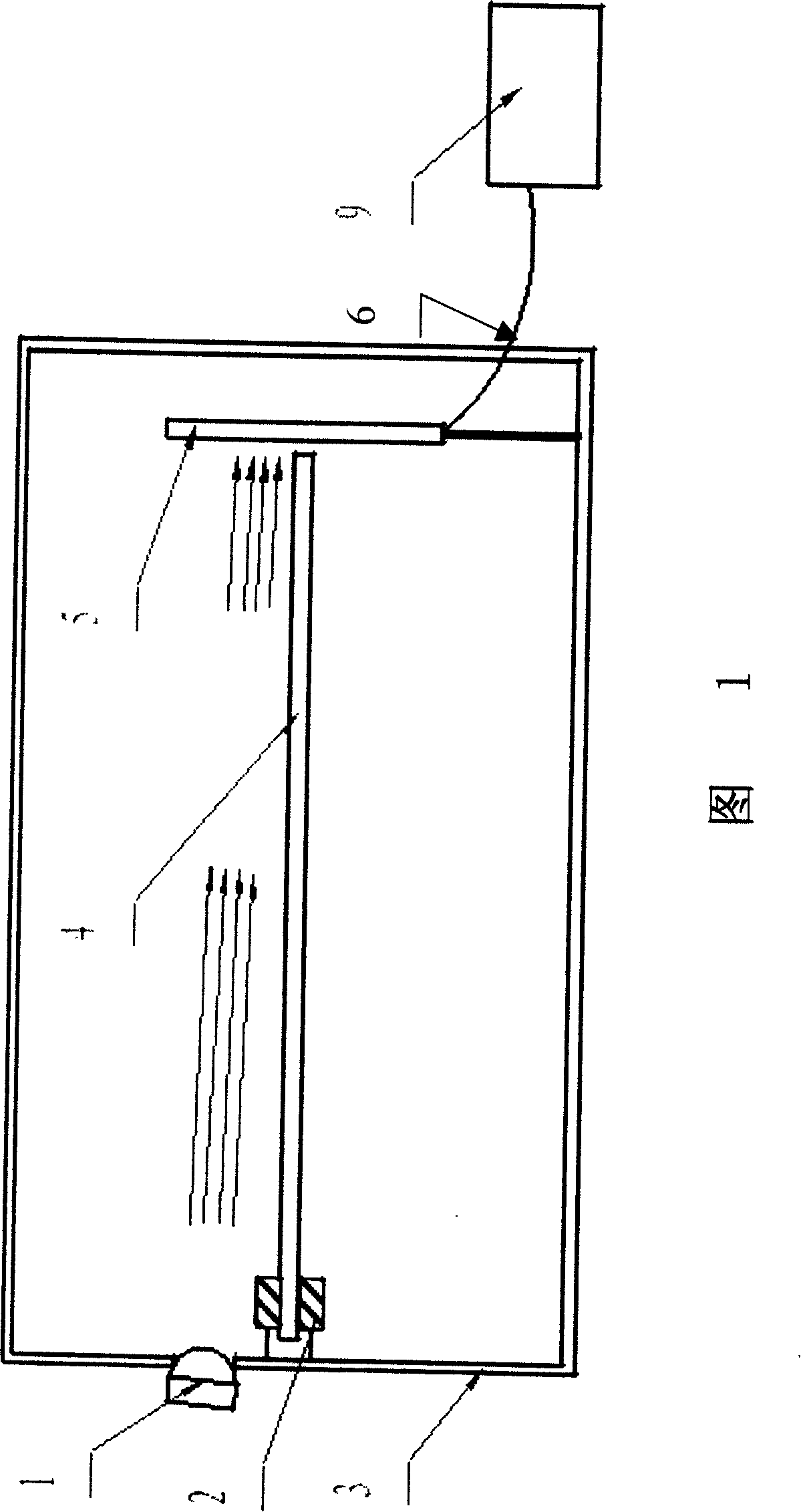

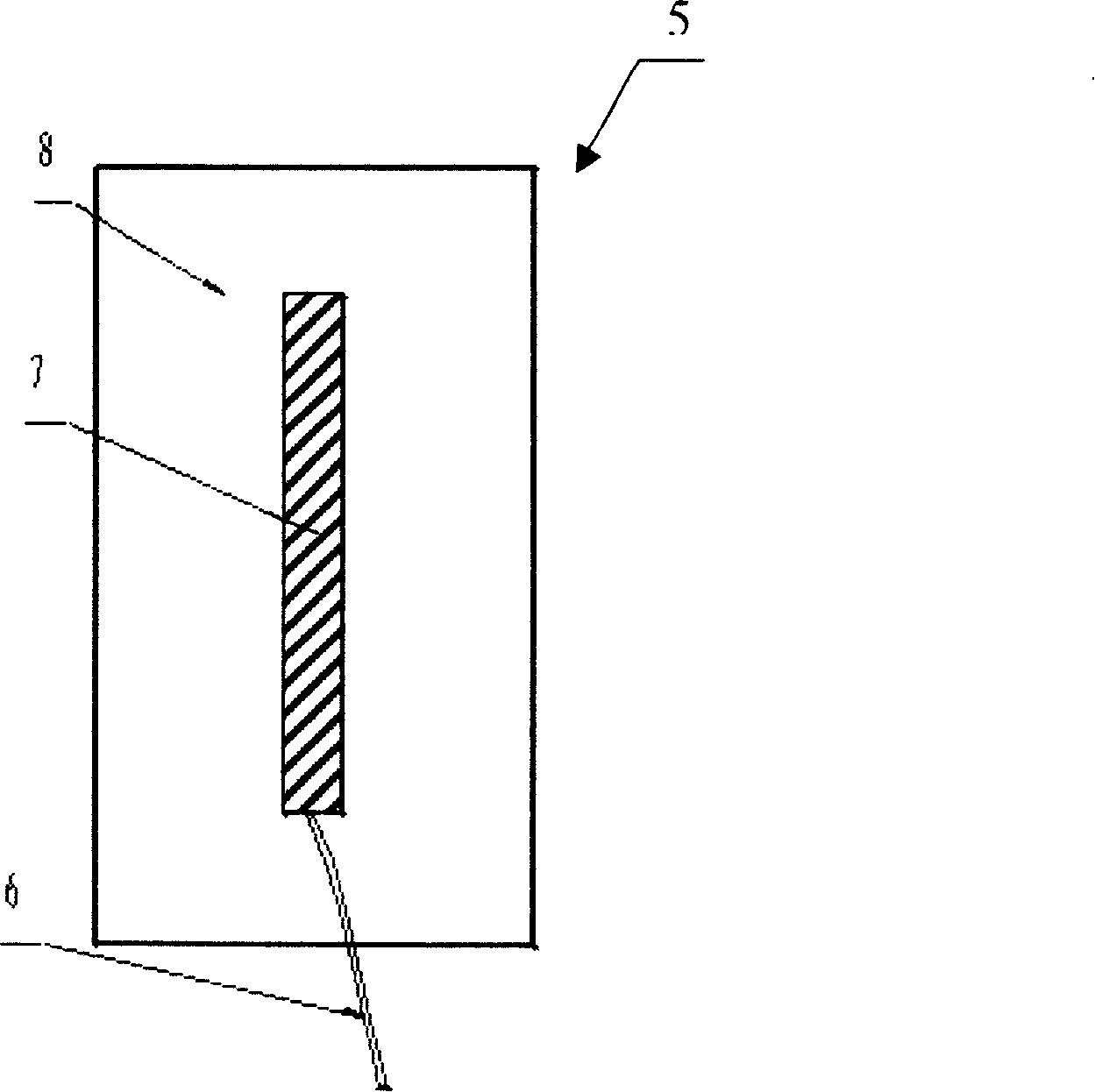

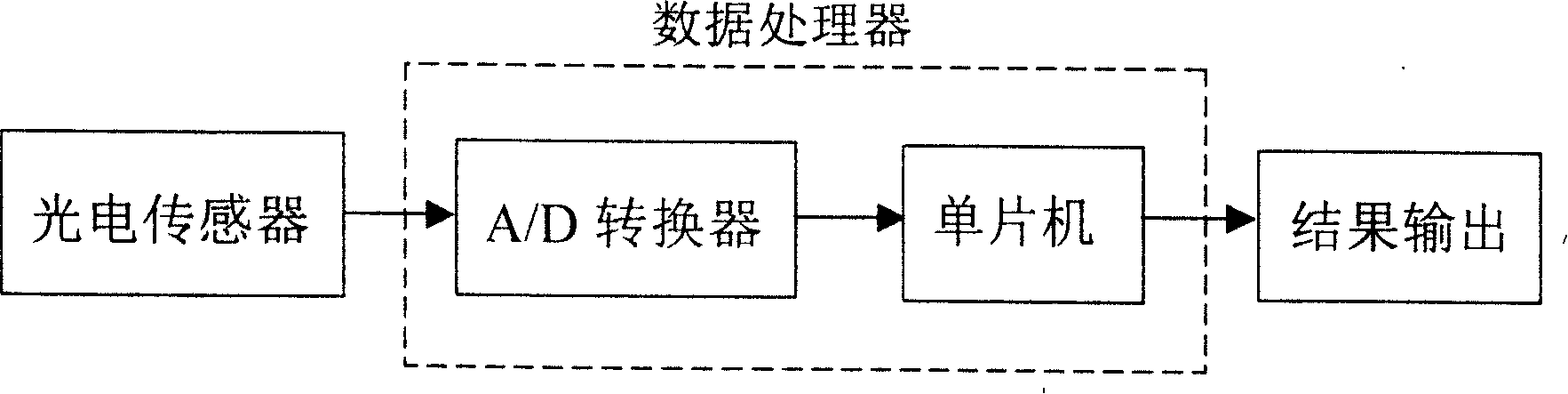

ActiveCN101178349ASimple structureReasonable structureUsing mechanical meansUsing optical meansDamping factorMicrocontroller

The invention relates to a device for measuring the damping factor of a material and a method for using the device to measure, belonging to the category of instrument measurement. The equipment is composed of a measuring device and a data processing device. The measuring device is mainly composed of a dark box, a light source, a fixture, and a photocell sensor. The fixture and the photocell sensor are located in the dark box. The light source is located on the side wall of the dark box and illuminates the photocell sensor in the dark box. Installed in the dark box opposite to the light source, the photocell sensor is connected with a signal lead-out line, the fixture and the light source are located on the same side, which corresponds to the middle position of the photocell sensor; the data processing device is mainly composed of A / D converter and single-chip microcomputer, A / D The converter is connected with the single-chip microcomputer, and the signal lead-out line of the photocell sensor is connected with the A / D converter. The above-mentioned device measures the material damping factor by means of photoelectric signal conversion. The invention has quick operation and convenient measurement, and can be widely used in the measurement field of solid materials.

Owner:GUOBIAO BEIJING TESTING & CERTIFICATION CO LTD

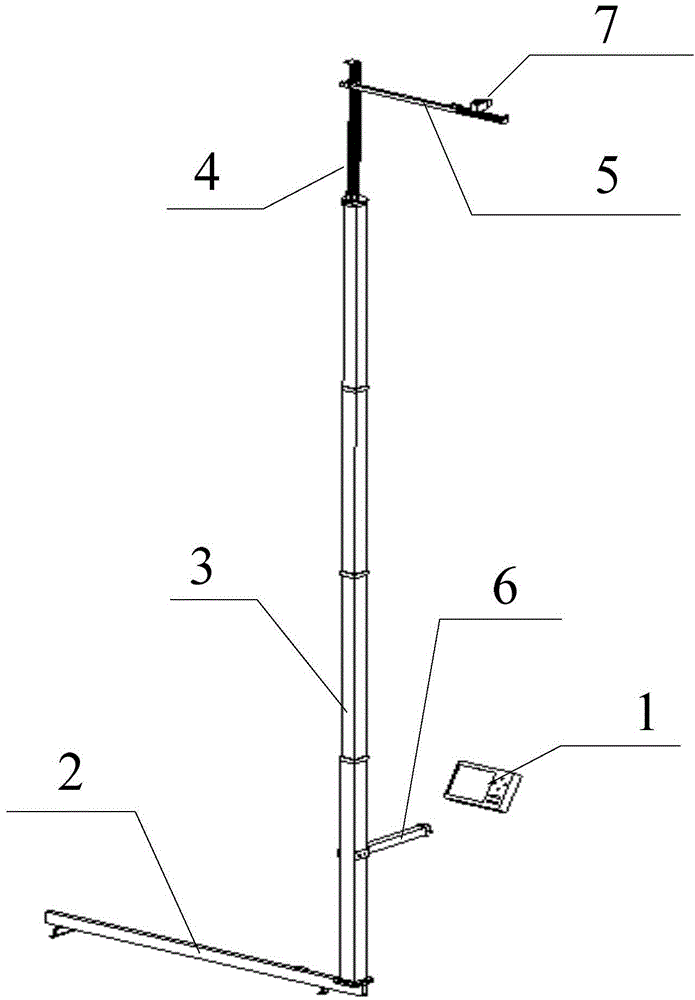

Movable type wave run-up precise measuring device

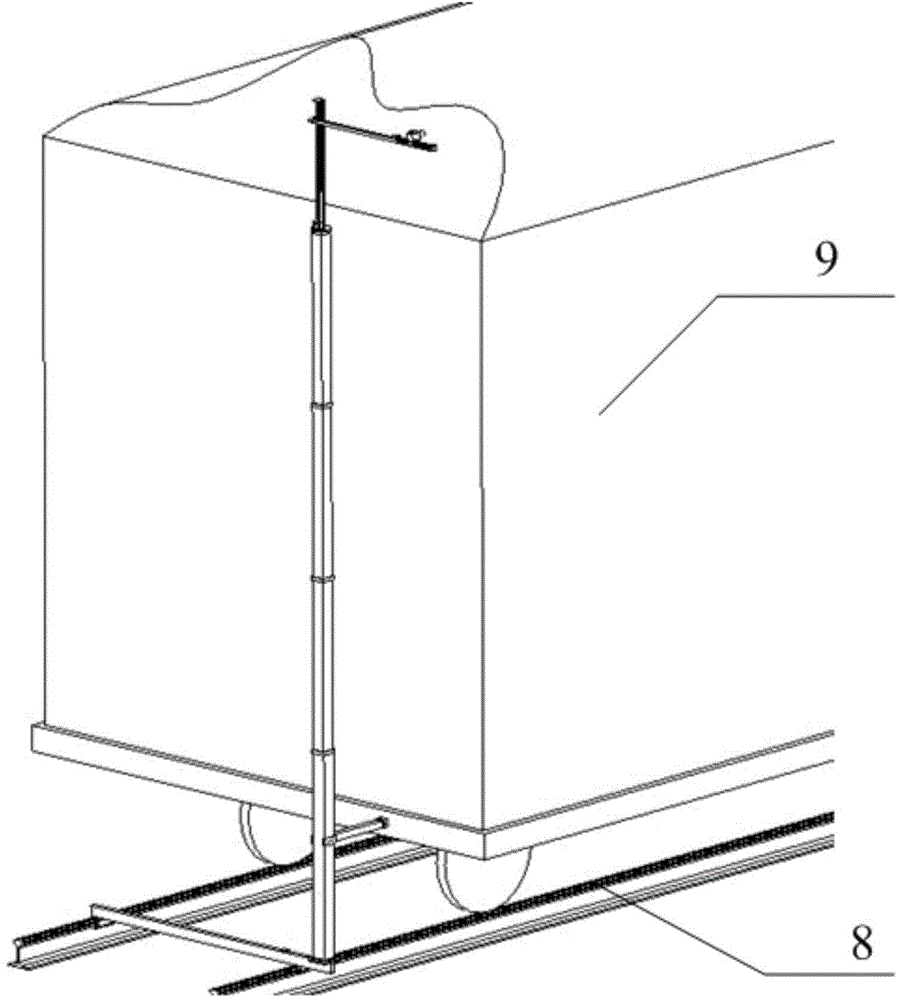

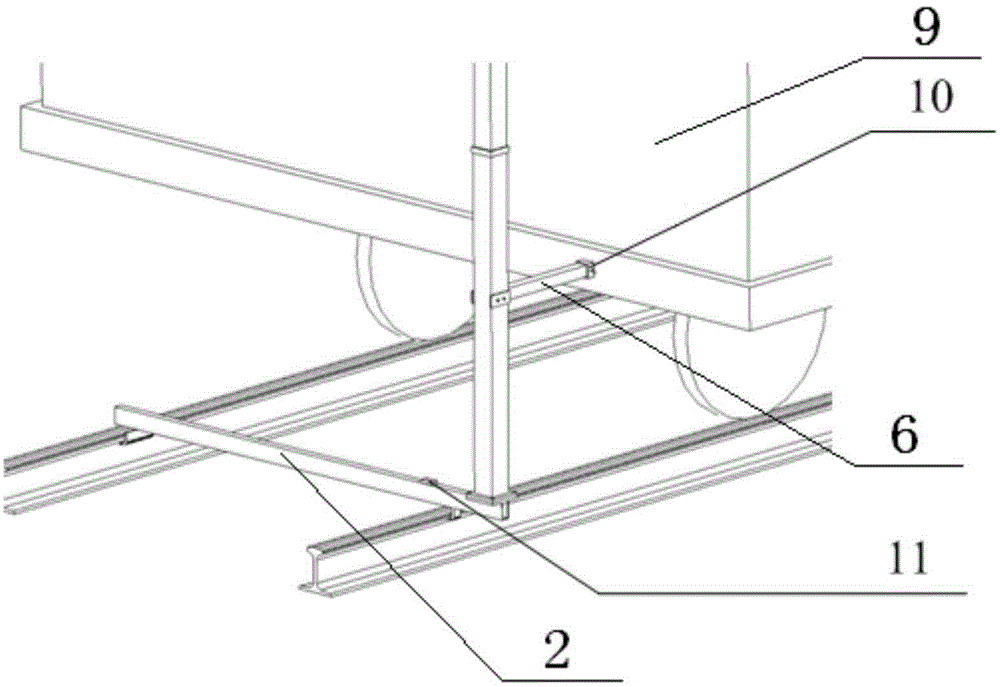

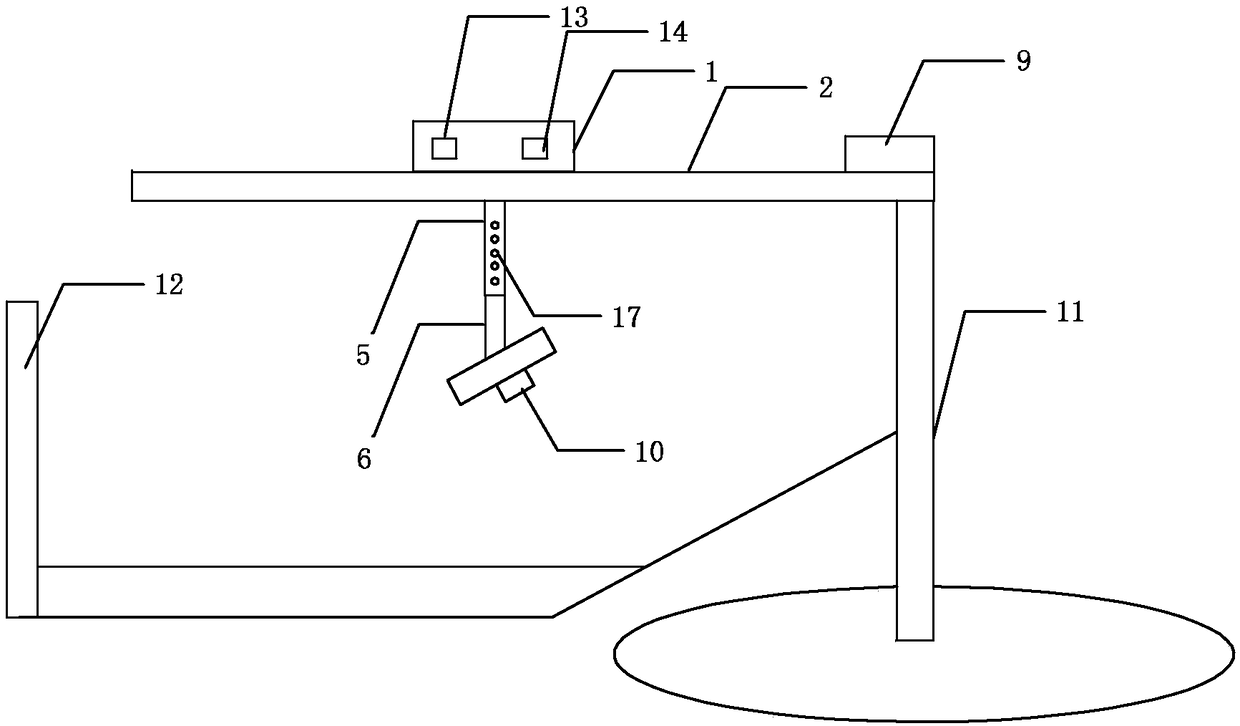

InactiveCN108180848AControllable and adjustable positionControllable and adjustable distanceUsing optical meansLaser rangingMeasurement device

The invention relates to a movable type measuring device for precisely measuring wave run-up by employing a camera, and solves the problem of inaccurate measurement of wave run-up in the prior art. The movable type wave run-up precise measuring device comprises an electric trailer, a guide rail, a camera, a support and a laser range finder, the guide rail is arranged on the support, the electric trailer is arranged in the guide rail in a sliding manner, the bottom end of the electric trailer is provided with a connecting pipe, a telescoping pipe is arranged in the connecting pipe in a slidingmanner, the lower end of the telescoping pipe is provided with the camera, the laser range finder is arranged at one end of the guide rail, the guide rail on a water tank is provided with the trailerwith a motor, the camera can move up and down and is parallel to a bank slope, a rod piece is adjusted to enable the traverse field of view of the camera to exactly exceed the width of the water tankso that the precision of results is improved, and the front of the trailer is provided with the laser range finder used for accurately measuring the position of the trailer so that the accuracy of run-up measuring results is improved, the measurement is accurate, and the efficiency is high.

Owner:ZHEJIANG OCEAN UNIV

Electromechanical detection method of non-metallic material thickness

InactiveCN1991294AAchieve thicknessTo achieve the purpose of measurementElectrical/magnetic thickness measurementsMetallic materialsComputational physics

The invention discloses an electromagnetic detecting method for the thickness of non-metallic material, a metal plate with finite thickness is lain on the back of the detected surface of the non-metallic material with known thickness, the electromagnetic inductive probe with driving winding coil and testing winding coil is closed to the detected surface, the pumping signal is generated by the driving winding coil, the electromagnetic signal obtained by the testing winding coil is processed to get the data corresponding to the known thickness of the non-metallic material, the thickness model of non-metallic material (includes air) is established, in the actual measurement, the thickness of non-metallic material can be detected with the same method by aid of the model. Using the method, the thickness of non-metallic material with any structure can be detected, and it can reach the measuring goal for the thickness of non-metallic material conveniently, speedily and effectively.

Owner:林俊明

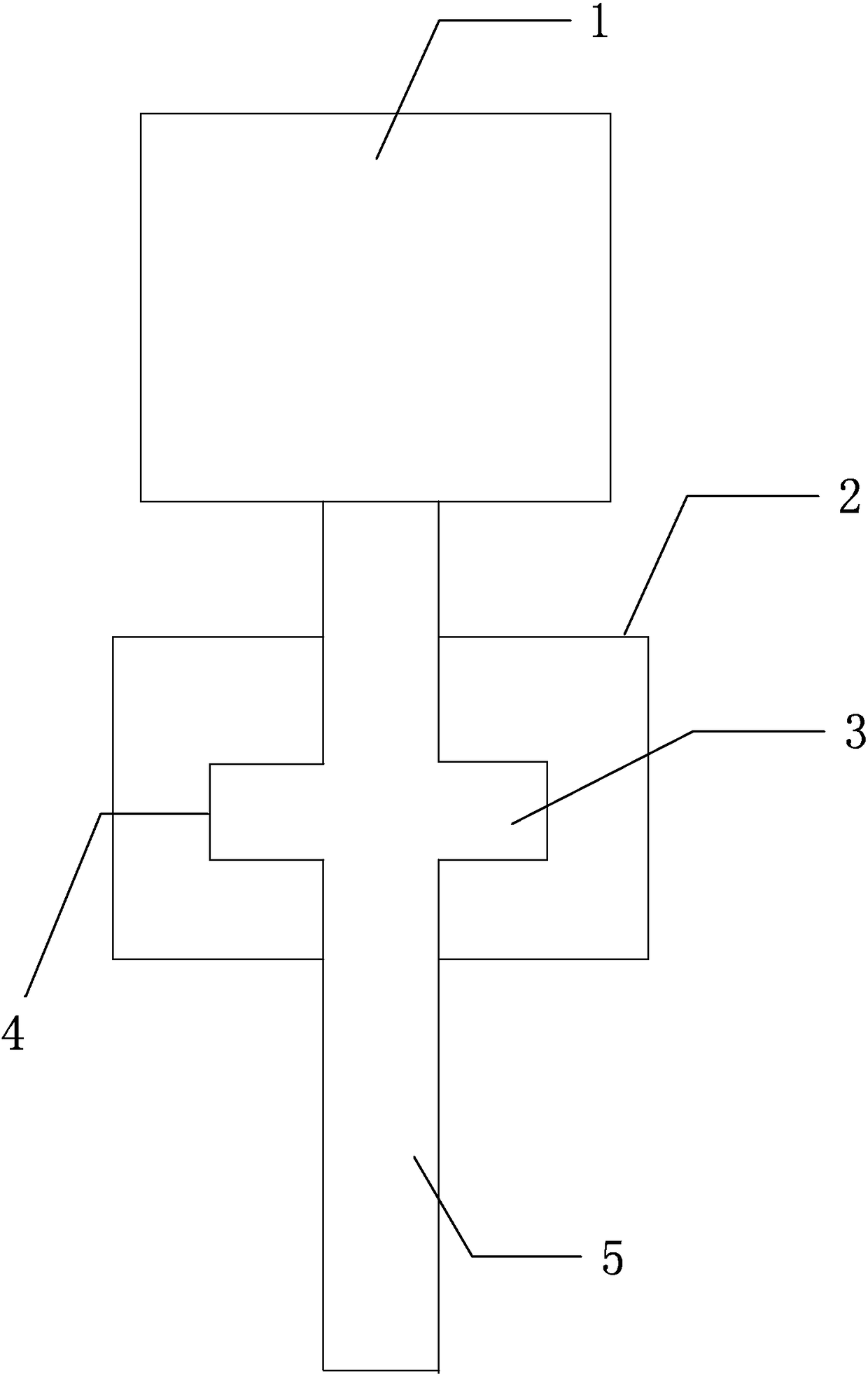

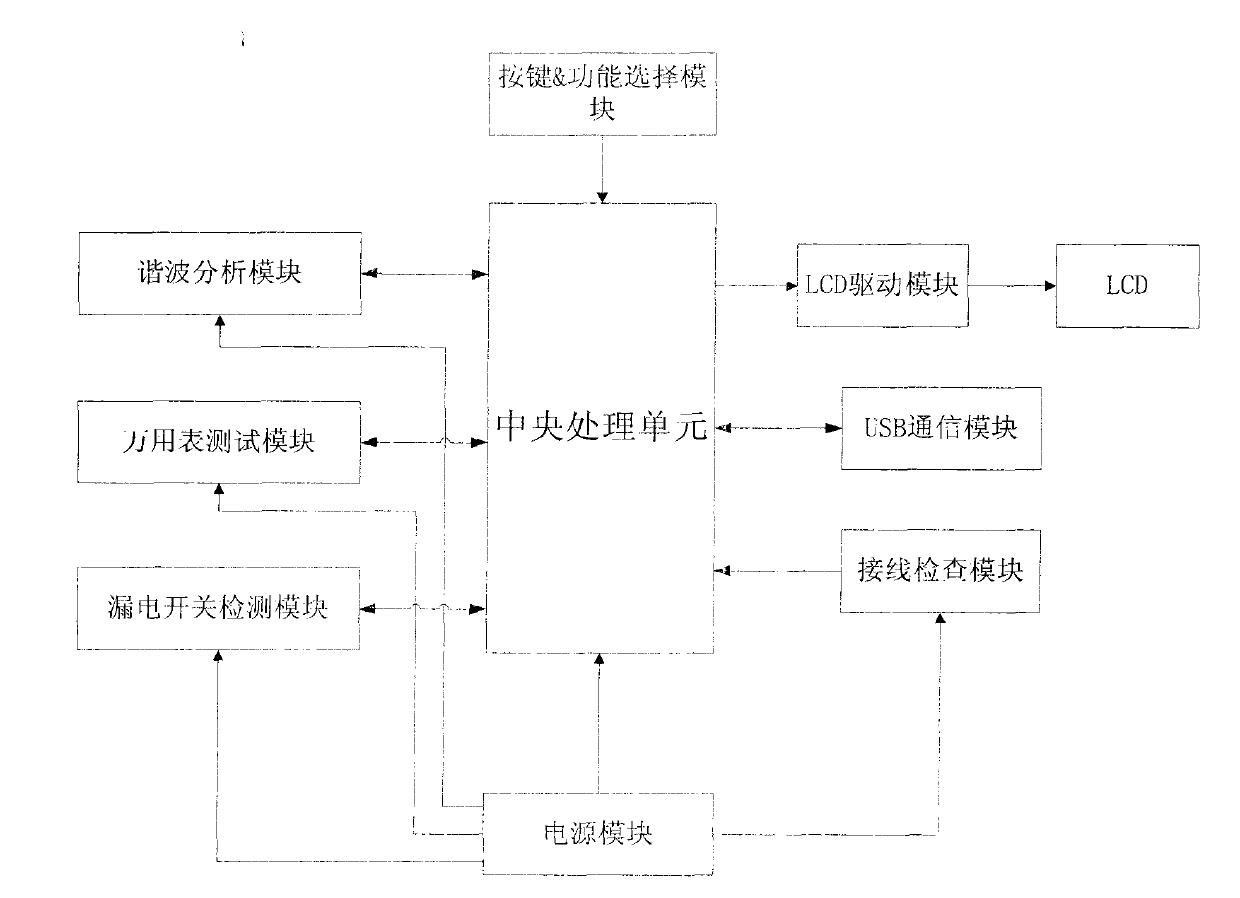

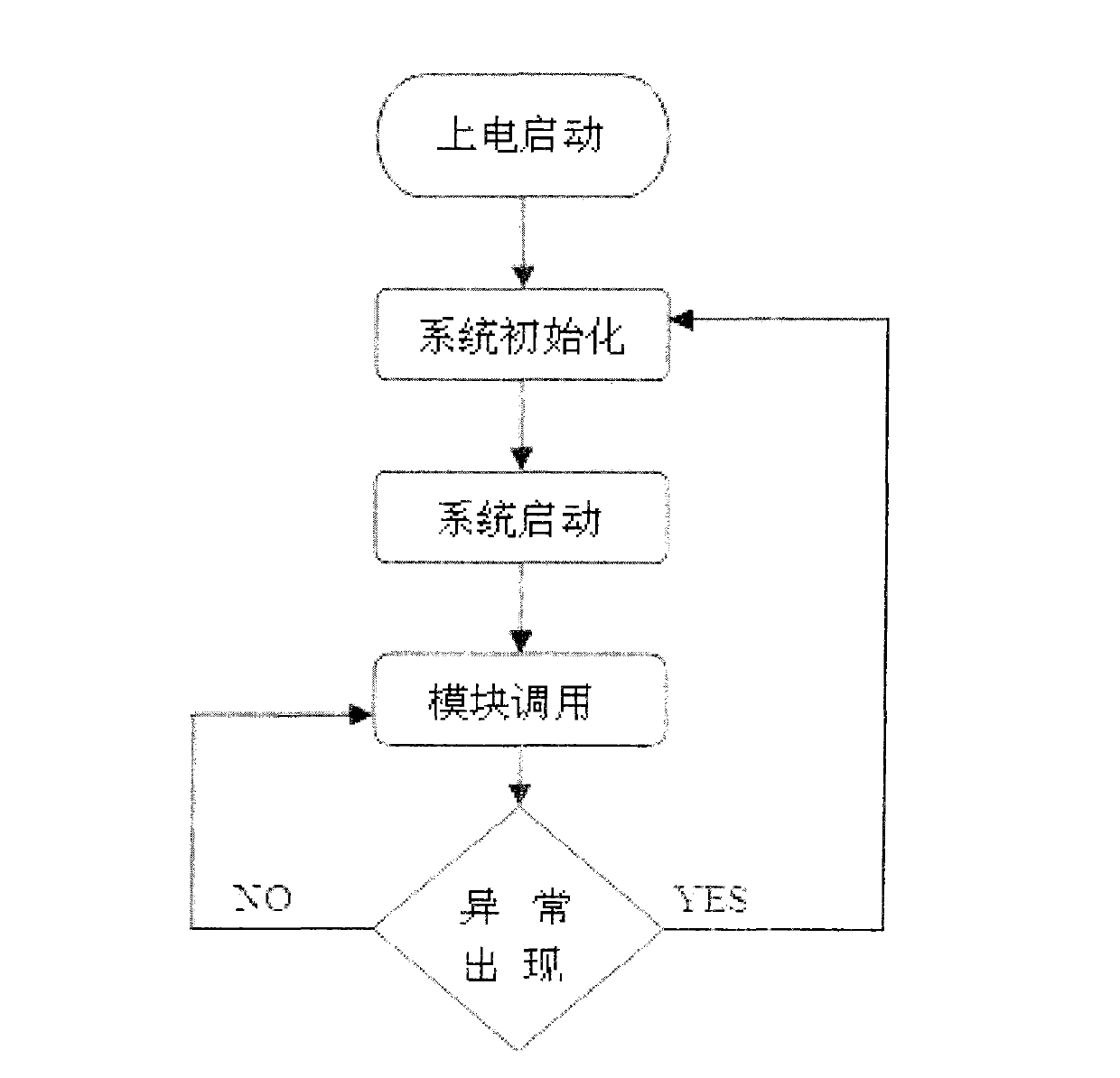

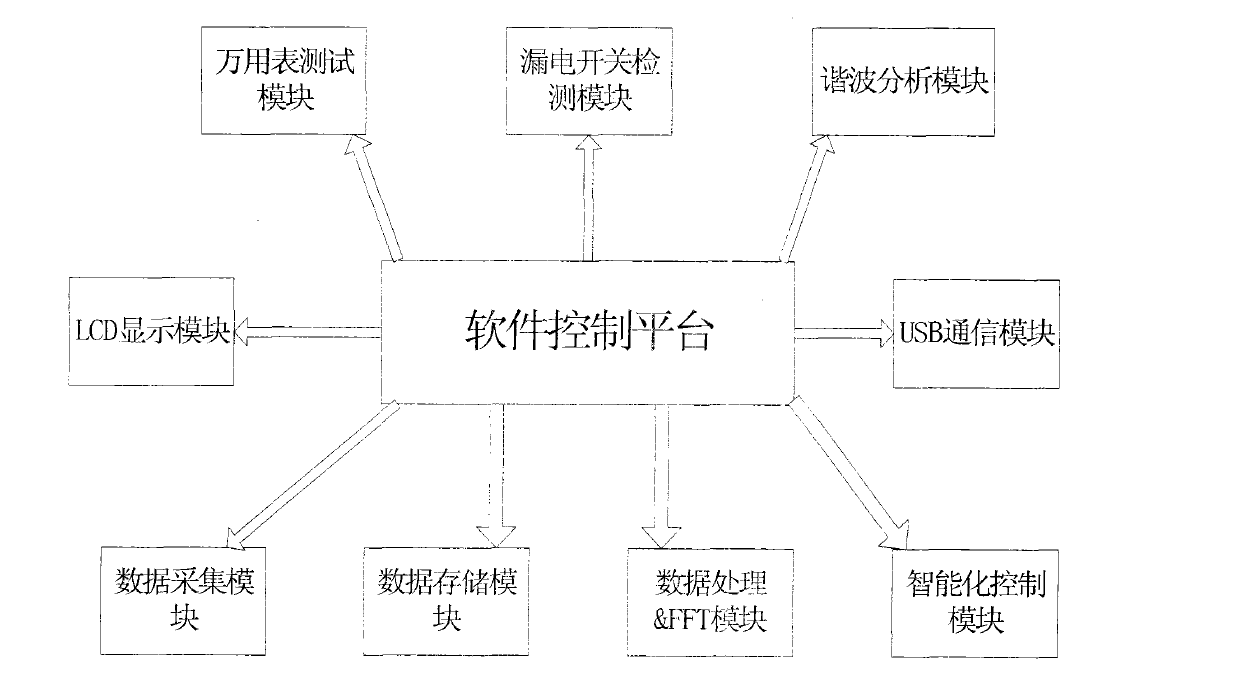

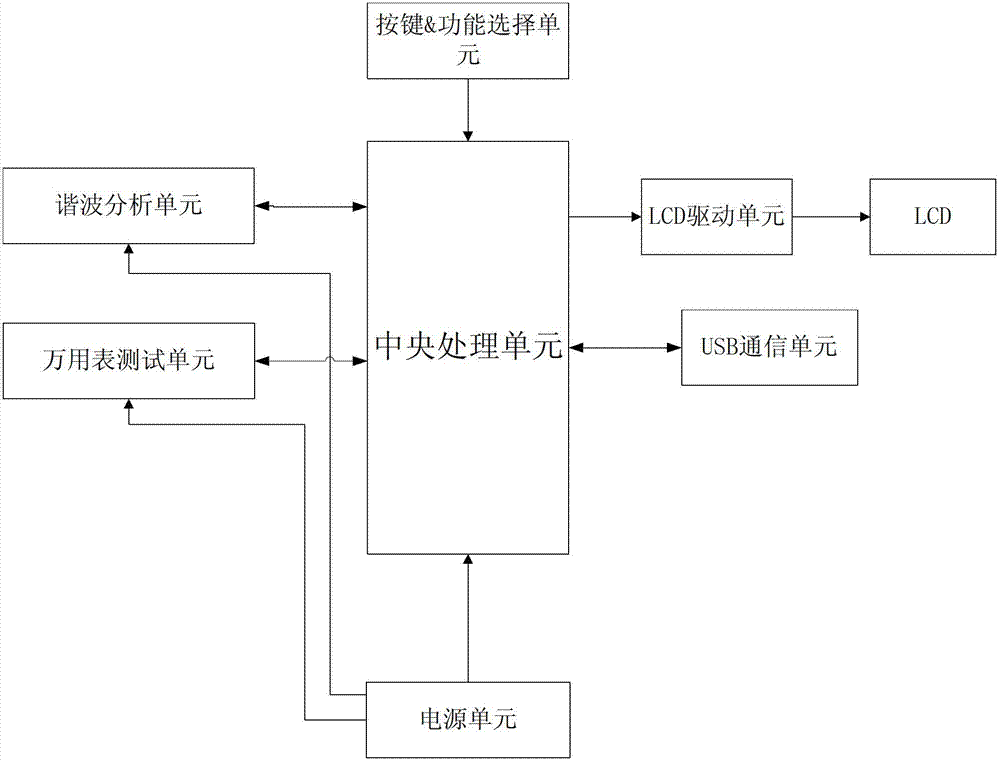

Electronic measurement method and device with compound functions

ActiveCN102680756AAccurate measurementTo achieve the purpose of measurementSpectral/fourier analysisMulti-tester circuitsMeasurement deviceElectricity

The invention discloses an electronic measurement method with compound functions. The method includes setting an electronic gauge, and setting a functional test unit and a central processing unit which are connected mutually inside the electronic gauge; setting a multimeter test module, a leakage switch detecting module and a harmonic analysis module in the functional test unit; setting a software control platform; and powering up and starting working, wherein the functional test unit starts to collect information sent by an information source and transmits the information to the central processing unit after collection; and the central processing unit processes and outputs the information. The invention further discloses an electronic measurement device with the compound functions. The electronic measurement method and device with the compound functions combine functions of multimeters, leakage switch detectors and harmonic analyzers together, the measurement is fast and convenient, the device is convenient to carry, the utilization is intelligent, and measuring accuracy is greatly improved combined with the additional functions.

Owner:UNI TREND TECH (CHINA) CO LTD

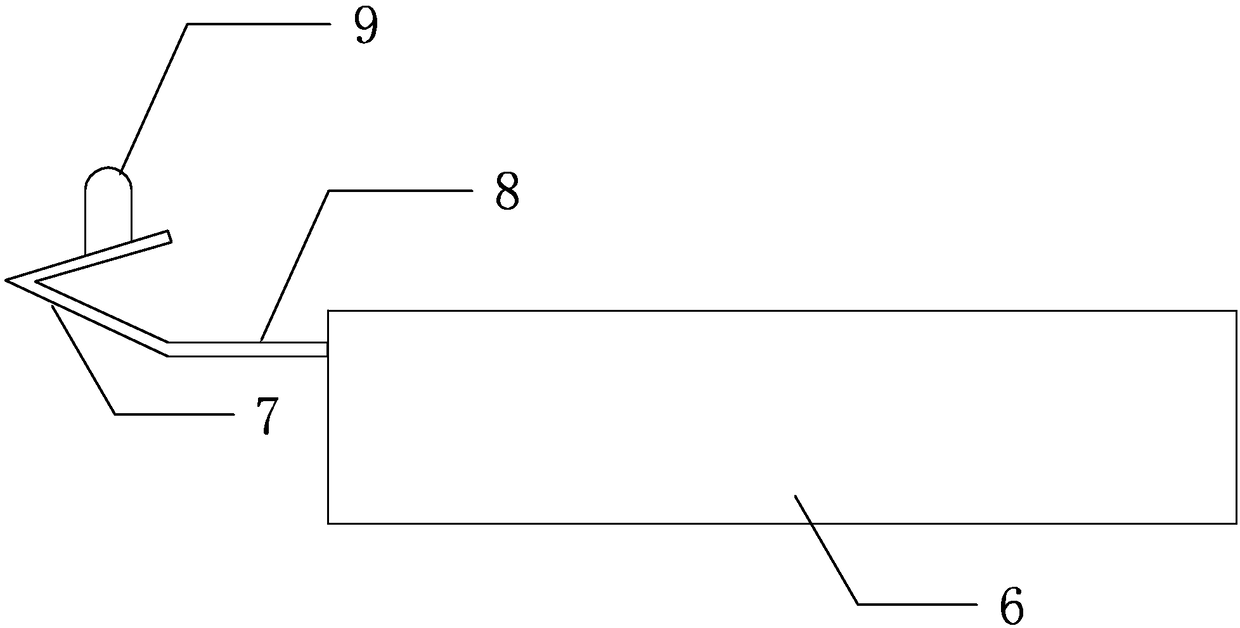

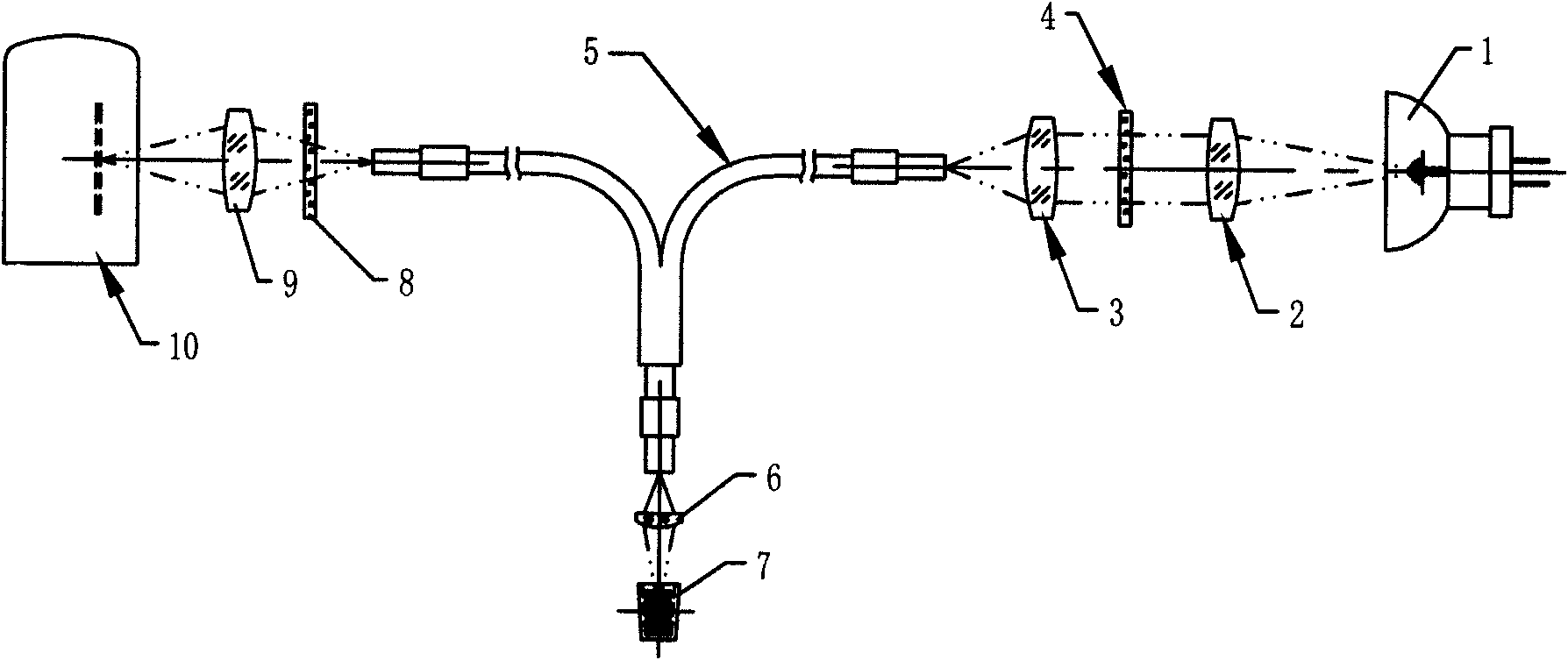

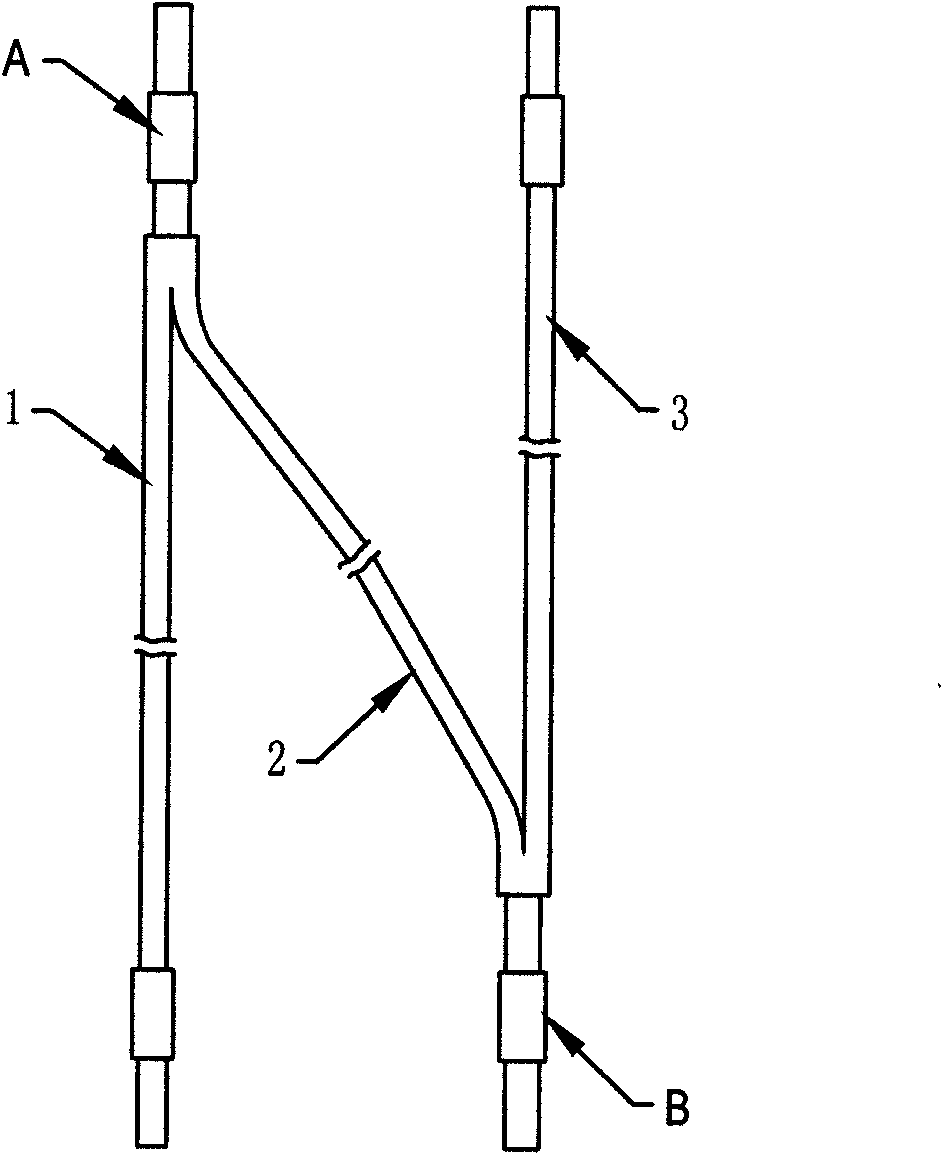

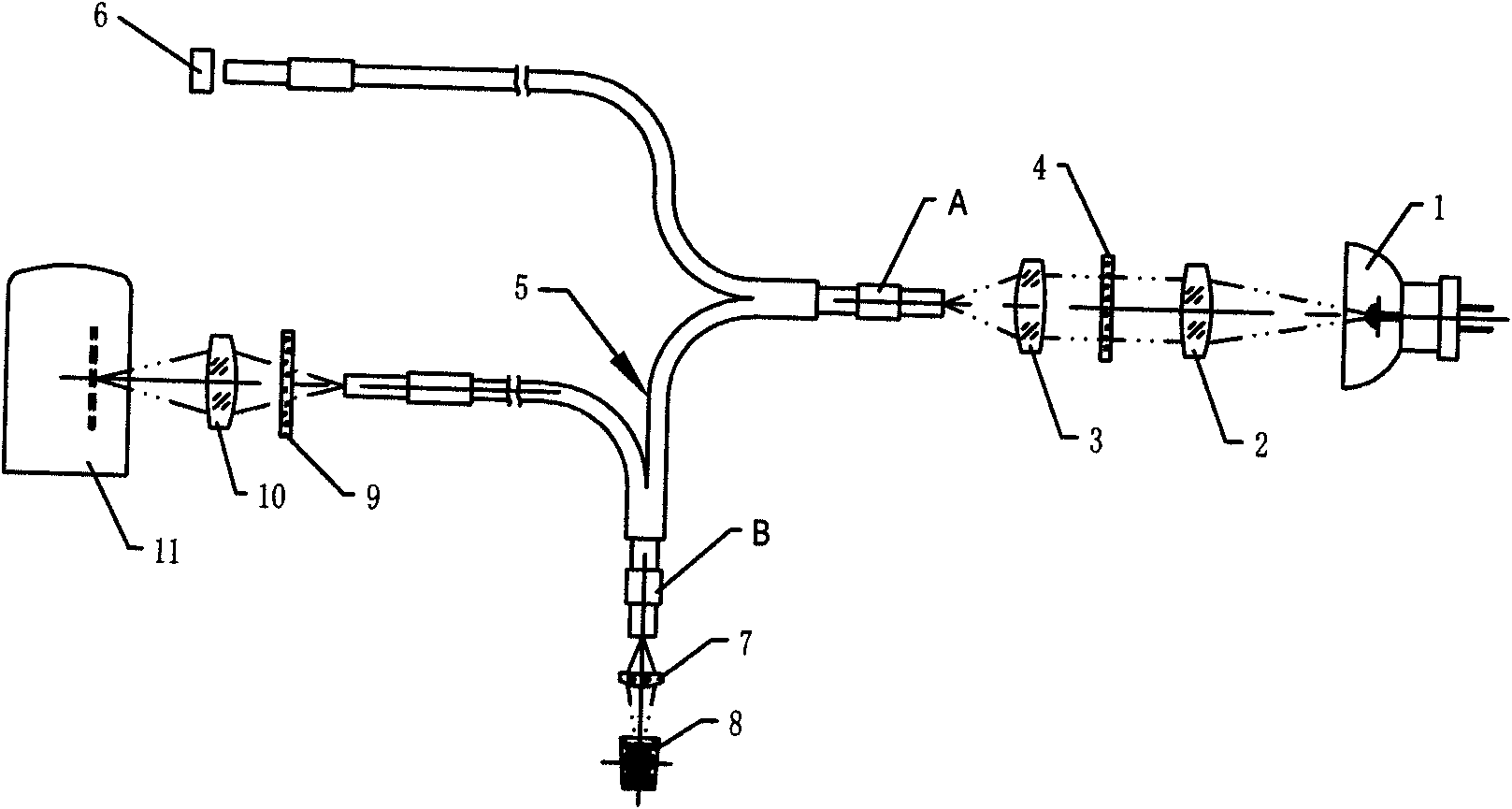

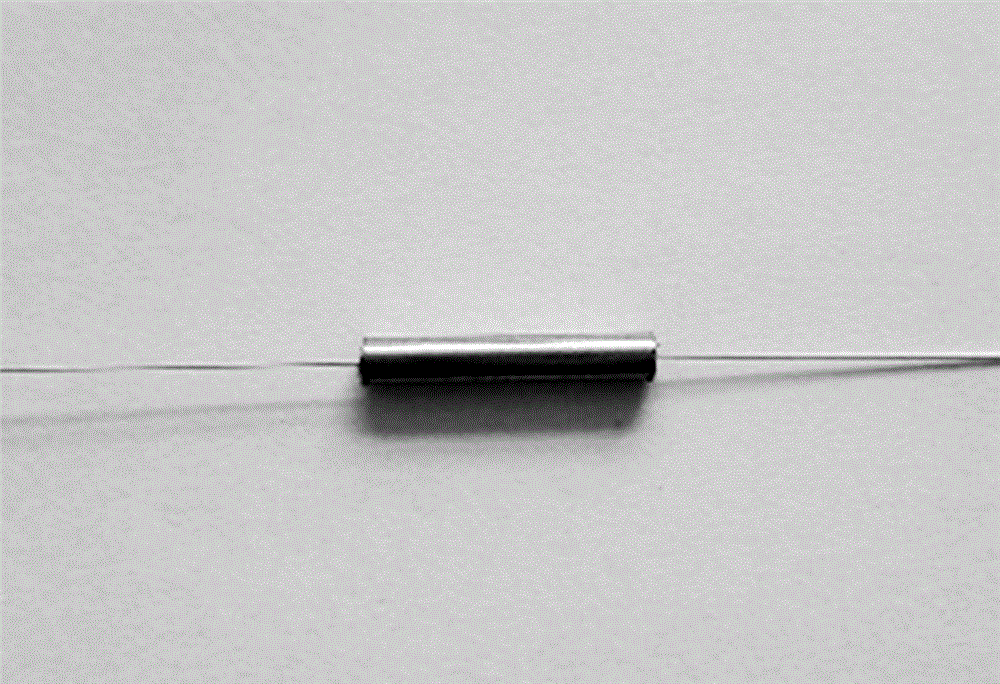

N type fiber coupler

ActiveCN101644795ATo achieve the purpose of measurementImprove stabilityCoupling light guidesFiber couplerFiber

The invention discloses an N type fiber coupler suitable for a fluorescence measuring system and a fiber sensing system. The structure of the N type fiber coupler is shown in picture 1 and the N typefiber coupler can be made of single-mould or multi-mould single-wire fibers or multi-wire optical fibers. The N type fiber coupler has the characteristics of two coupling ends: when the fiber coupleris made of the single-wire fibers, the fiber coupler is made of three single-wire fibers 1, 2 and 3; one side of the single-wire fiber 1 and one side of the single-wire fiber 2 are coupled into a coupling end A; the other end of the single-wire fiber 2 and one side of the single-wire fiber 3 are coupled into a coupling end B; the making technology of a universal Y type fiber coupler and an X typefiber coupler can be used for finishing the coupling step and when the fiber coupler is made of the multi-wire optical fibers, the fiber coupler is made of three optical fiber wires 1, 2 and 3 according to required bundle diameter. The N type fiber coupler is especially suitable for the fluorescence measuring system of top excitation and top reception and the fluorescence measuring system of the Ntype fiber coupler has the advantage of synchronously transmitting exciting light signals, fluorescence signals and three-way optical signals for monitoring light source intensity.

Owner:广州市丰华生物股份有限公司

Preparation method of fiber bragg grating temperature sensor with star sensitive lens structure

InactiveCN109612603AAccurate measurementMeet the environmental requirements of the workThermometers using physical/chemical changesThermometer testing/calibrationFiberGrating

The invention discloses a preparation method of a fiber bragg grating temperature sensor with a star sensitive lens structure. The preparation method of the fiber bragg grating temperature sensor withthe star sensitive lens structure is characterized in that the preparation method of the fiber bragg grating temperature sensor with the star sensitive lens structure comprises the following steps that (1) before the fiber bragg grating temperature sensor is packaged, mechanical simulation analysis is carried out on the fiber bragg grating temperature sensor; (2) strain measurement is carried outon the fiber bragg grating temperature sensor; (3) the fiber bragg grating temperature sensor is packaged; and (4) the fiber bragg grating temperature sensor is calibrated. The environmental requirements of spacecraft operation can be met, and the purpose of measurement is achieved. The temperature measurement is realized by adopting a novel packaging form. The multi-point temperature measurementfunction of a single sensor is realized, and a grid area is arc-shaped and hung on a substrate, so that the strain influence caused by deformation of the substrate is greatly reduced, and the temperature measurement is more accurate.

Owner:BEIJING INFORMATION SCI & TECH UNIV

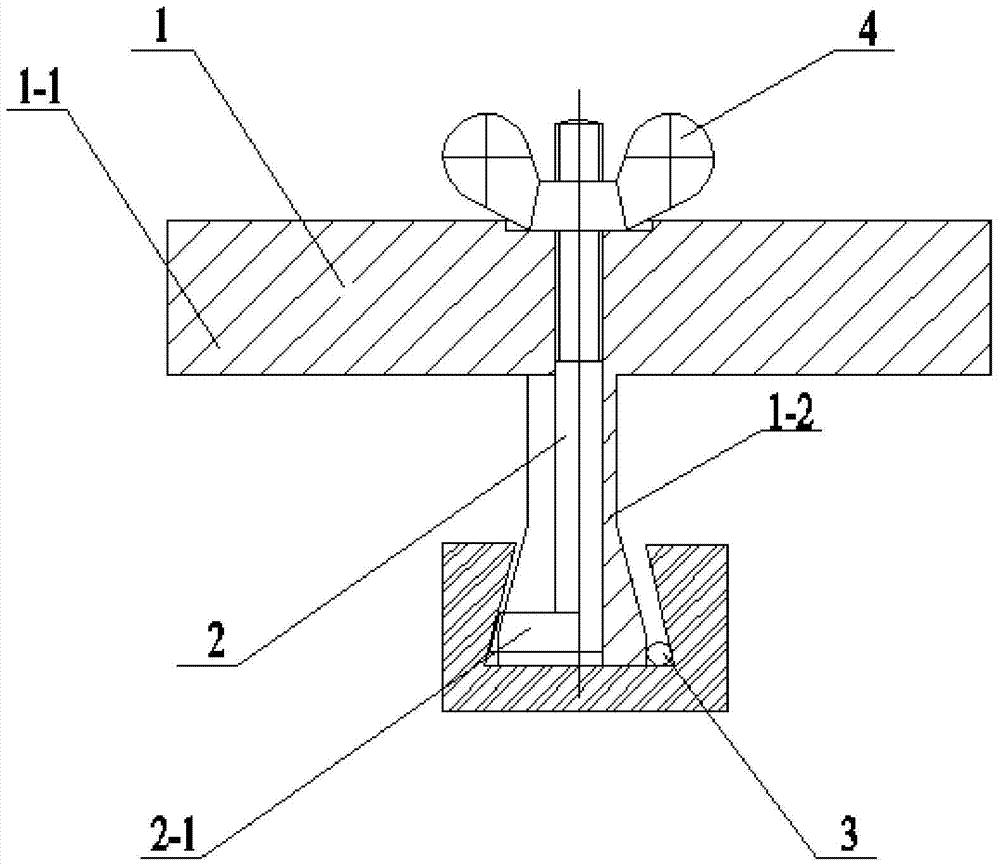

Measuring tool for dovetail groove of gas turbine disk and measuring method using same

InactiveCN104501754AEasy detectionTo achieve the purpose of measurementMechanical depth measurementsMechanical diameter measurementsGas turbinesEngineering

The invention provides a measuring tool for a dovetail groove of a gas turbine disk and a measuring method using the same. The invention relates to a measuring tool and a measuring method using the tool. The measuring tool and the measuring method solve problems that the horizontal plane range from the bottom surface of a dovetail groove of an existing gas turbine disk to the central line of the disk belongs to space structure and cannot be measured directly. The measuring tool for a dovetail groove of a gas turbine disk comprises a measuring body, a pull rod, a pulley, a nut, a baffle plate, and screws. The measuring method using the measuring tool for a dovetail groove of a gas turbine disk comprises the following: installing a dovetail groove shaped measuring bottom into the dovetail groove of the disk, the baffle plate tightly abutting against the side surface of the disk, and screwing the nut, so that the measuring body compresses the bottom surface of the disk dovetail groove along the pulley, until the edge center point of the bottom end of the dovetail groove shaped measuring bottom is overlapped with the bottom end edge center point of the disk dovetail groove, and measuring and calculating to obtain the horizontal plane range from the bottom end edge center point of the disk dovetail groove to the central line of the disk. The invention relates to a measuring tool for a dovetail groove of a gas turbine disk and a measuring method using the same.

Owner:HARBIN TURBINE

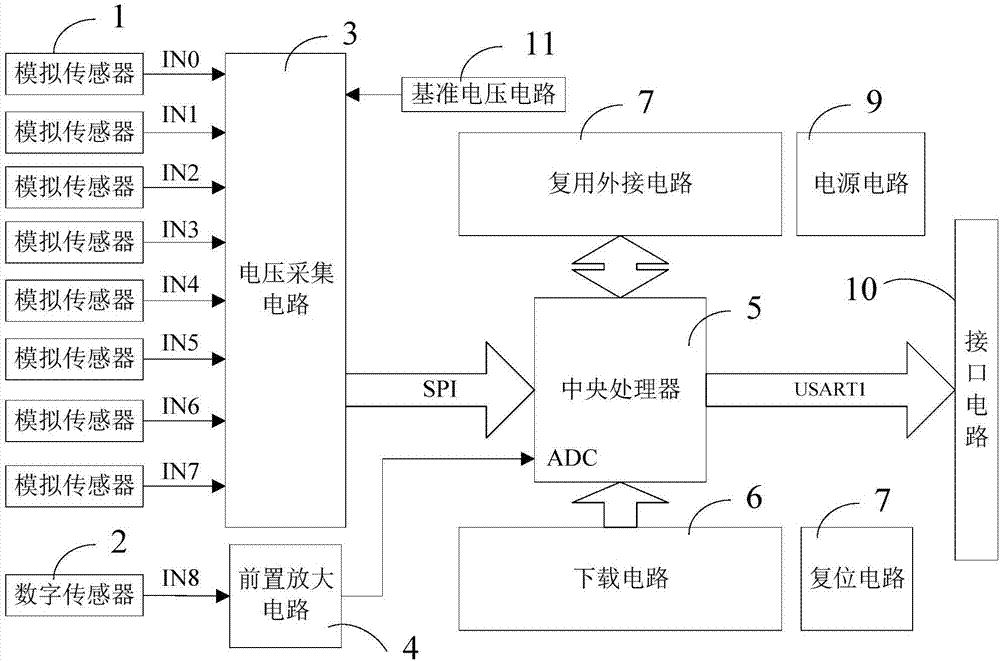

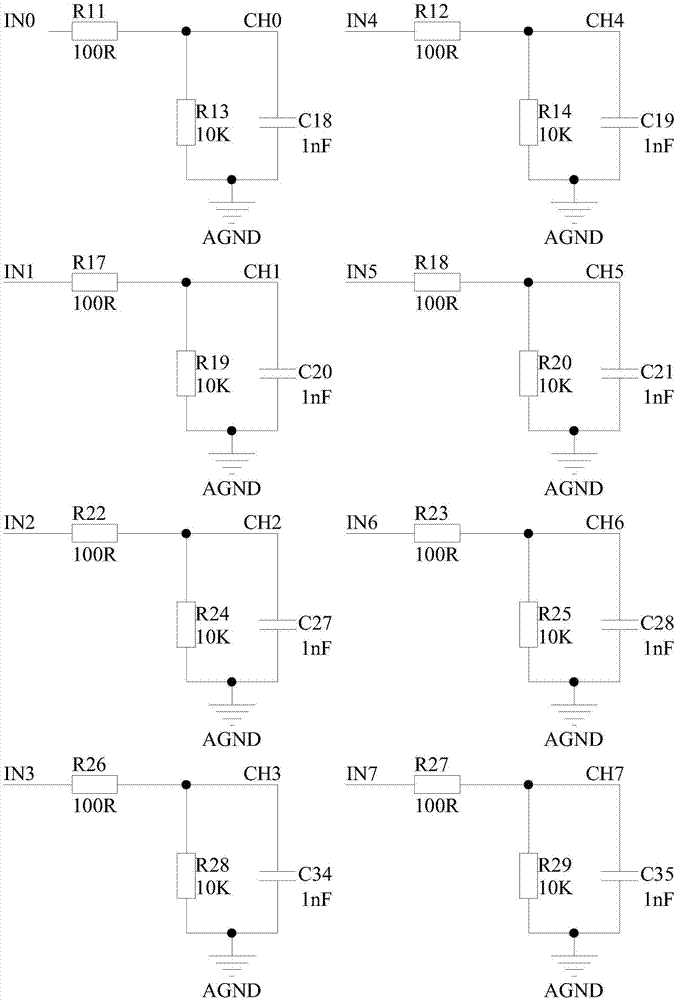

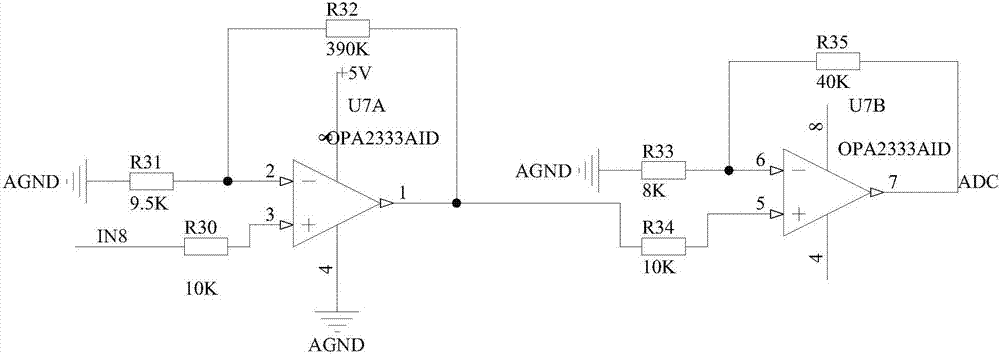

Multi-channel mixed signal acquisition system for medical rehabilitation equipment

ActiveCN107121958AEnable hybrid measurementsConvenient real-time displayProgramme controlComputer controlEngineeringMedical treatment

The invention discloses a multi-channel mixed signal acquisition system for medical rehabilitation equipment. The system comprises eight analog sensors, a digital sensor, a voltage acquisition circuit, a pre-amplification circuit and a central processing unit, wherein the analog sensors are used for detecting pressure of wrist joints of two hands, elbow joints, shoulder joints and hands respectively and outputting eight corresponding voltage signals in real time; the digital sensor is used for detecting the rate of the heart and outputting corresponding electrocardio pressure signals in real time; the voltage acquisition circuit collects eight voltage signals and converts the voltage signals into one input signal ADC; the central processing unit receives an input signal DOUT and the input signal ADC and form one serial data for transmission. The system is mainly applied to accurate signal acquisition of the medical rehabilitation equipment in the medical rehabilitation field, realizes simultaneous and real-time acquisition of multiple signals, achieves the purpose of measurement of complicated signals and mixed measurement of multiple signals and also facilitates real-time display on an upper computer.

Owner:合肥哈工力训智能科技有限公司

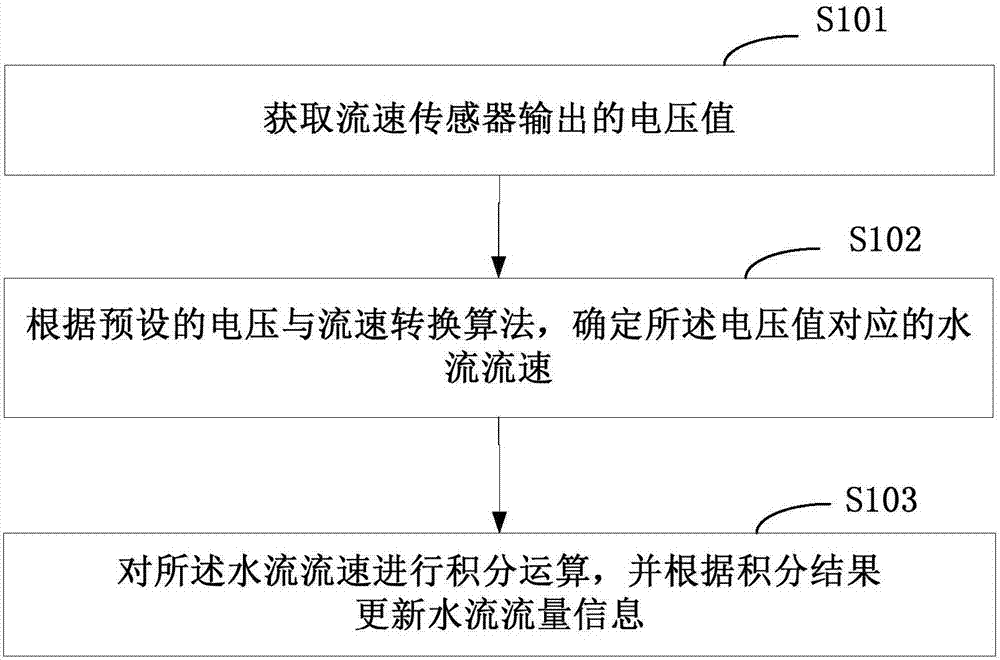

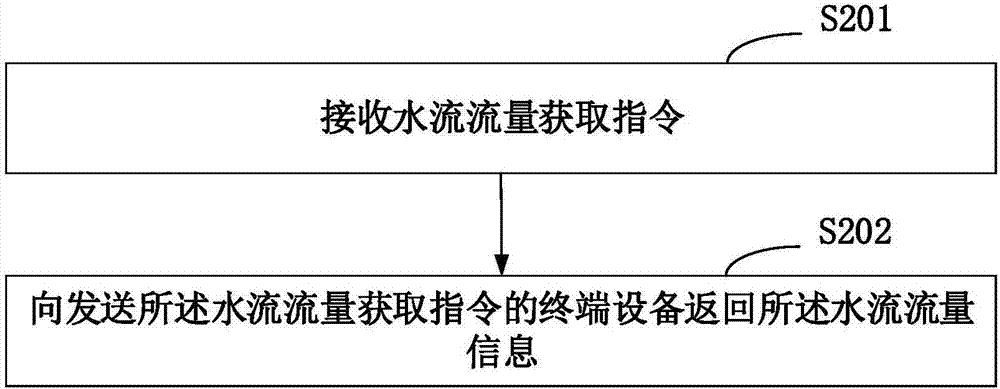

Water flow metering method and device

InactiveCN107228692ATo achieve the purpose of measurementEnvironmental factors have little influenceVolume/mass flow measurementWater flowEngineering

The invention is suitable for the technical field of flow metering and provides a water flow metering method and device. The method includes: acquiring a voltage value output by a flow speed sensor; determining water flow speed corresponding to the voltage value according to a preset voltage-flow speed conversion algorithm; integrating the water flow speed, and updating water flow information according to an integration result. By placing the flow speed sensor in a to-be-measured water flow area, when water flow passes the flow speed sensor at a certain flow speed, a voltage value having a certain corresponding relationship with the flow speed is generated, the water flow metering device acquires the voltage value, the water flow speed corresponding to the voltage value is acquired by calculating according to the preset voltage-flow speed conversion algorithm, and the water flow information is updated according to integration of the water flow speed, so that the objective of water flow metering is achieved, and the problem that existing water flow metering technology is low in accuracy and highly subject to influence of manufacturing process.

Owner:深圳龙电华鑫控股集团股份有限公司

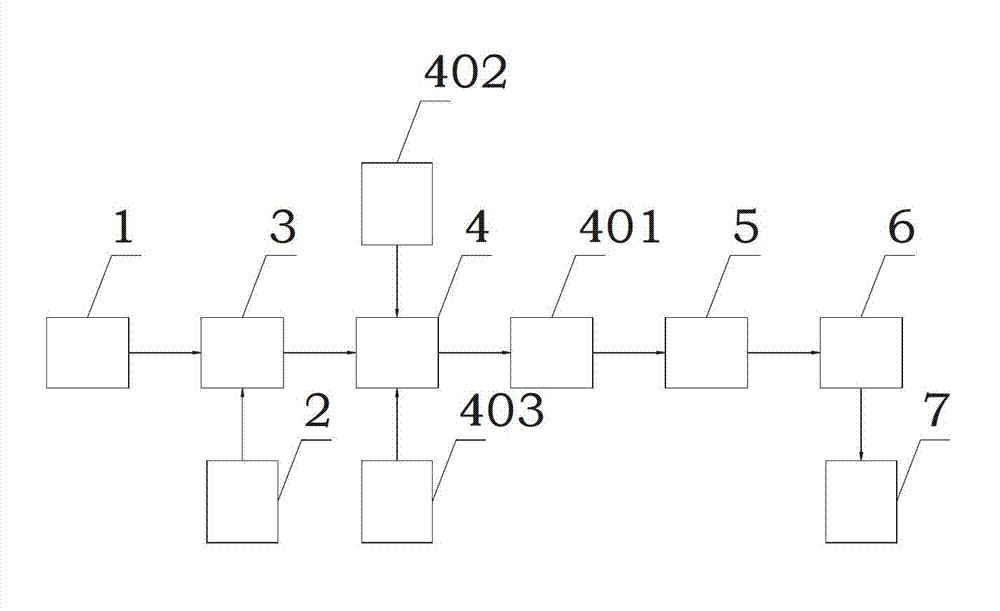

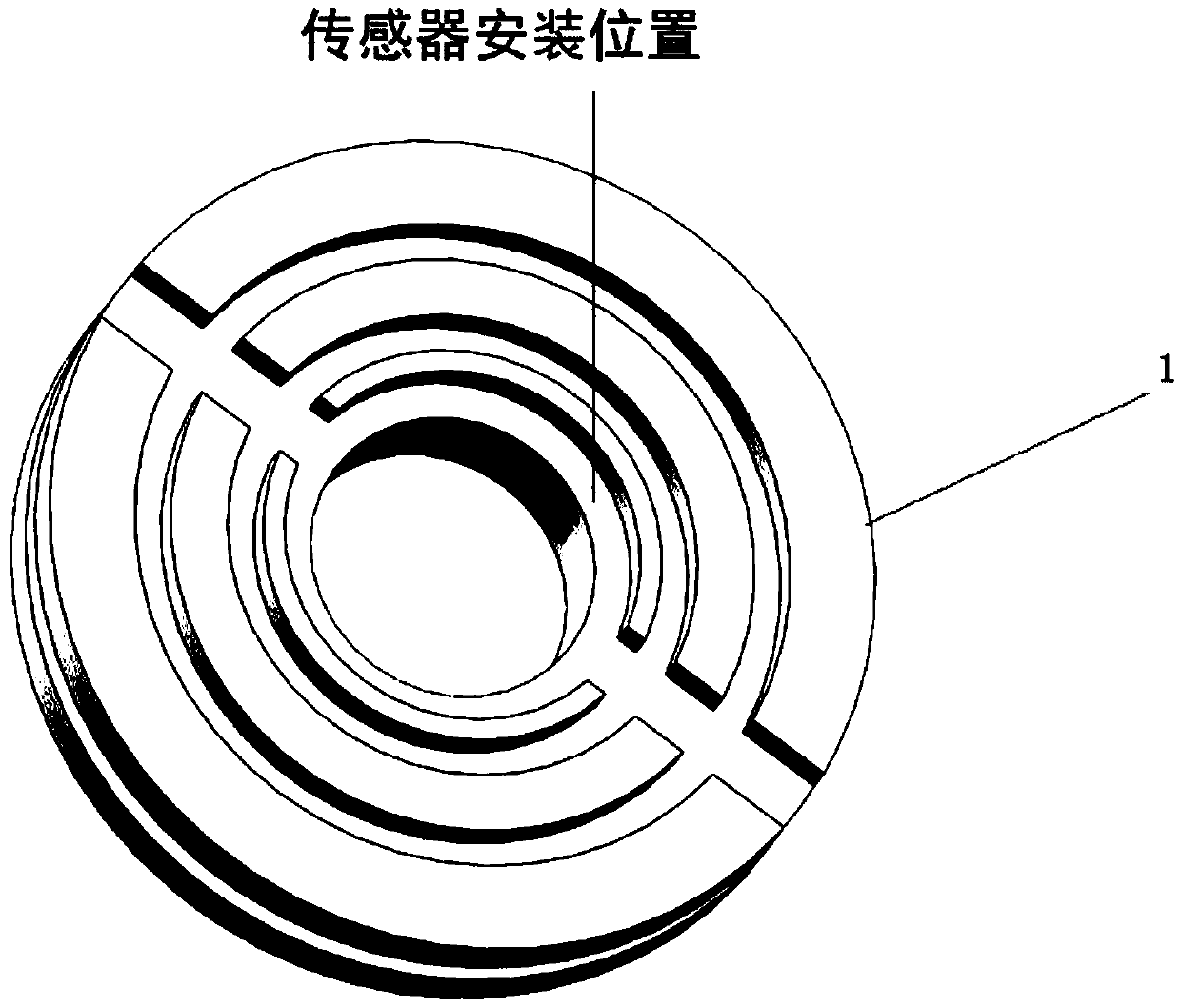

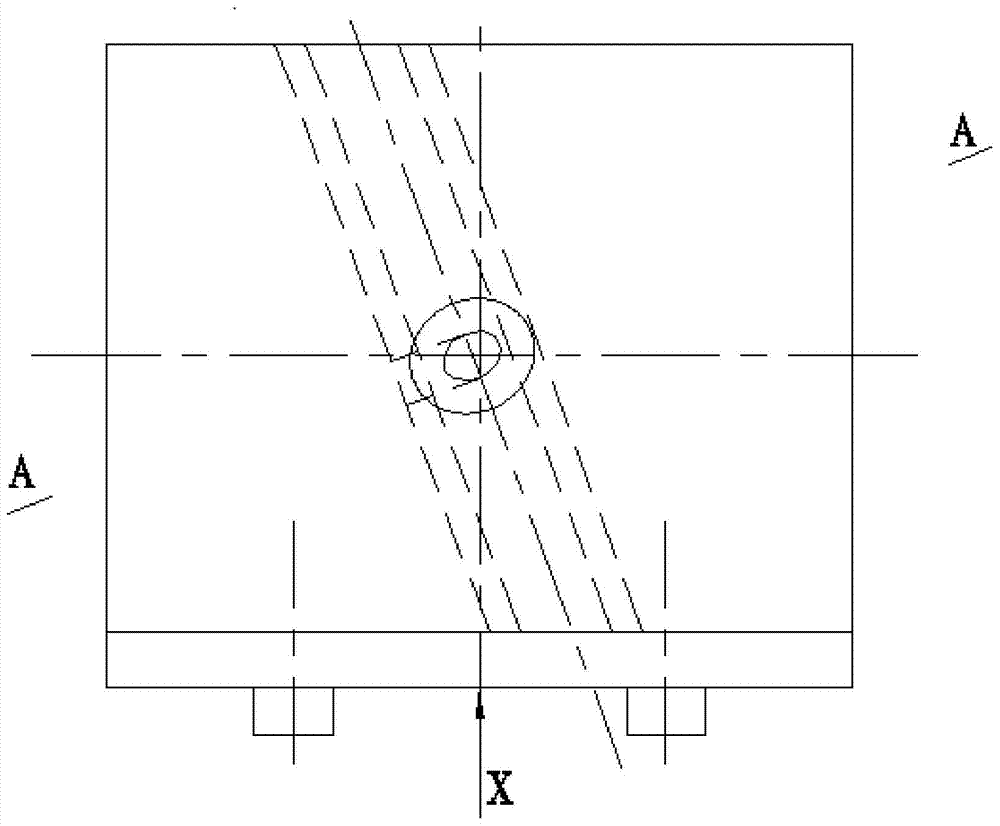

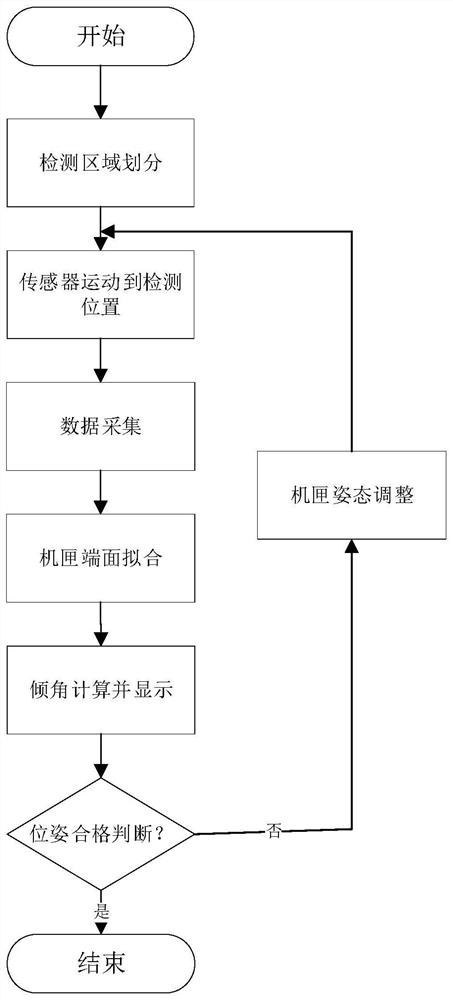

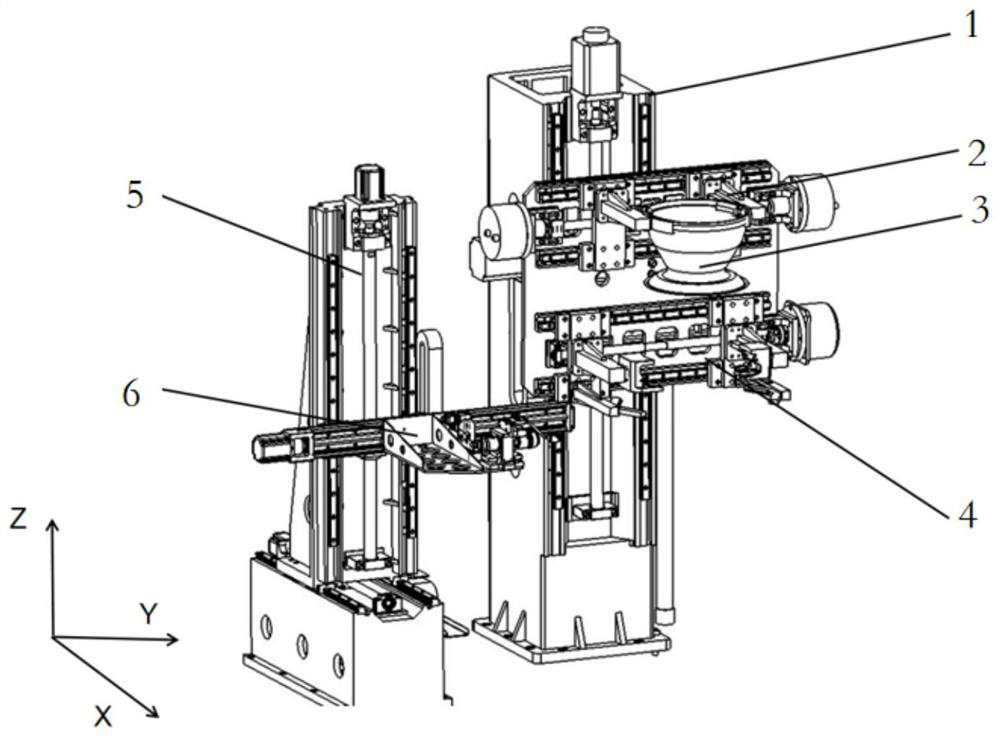

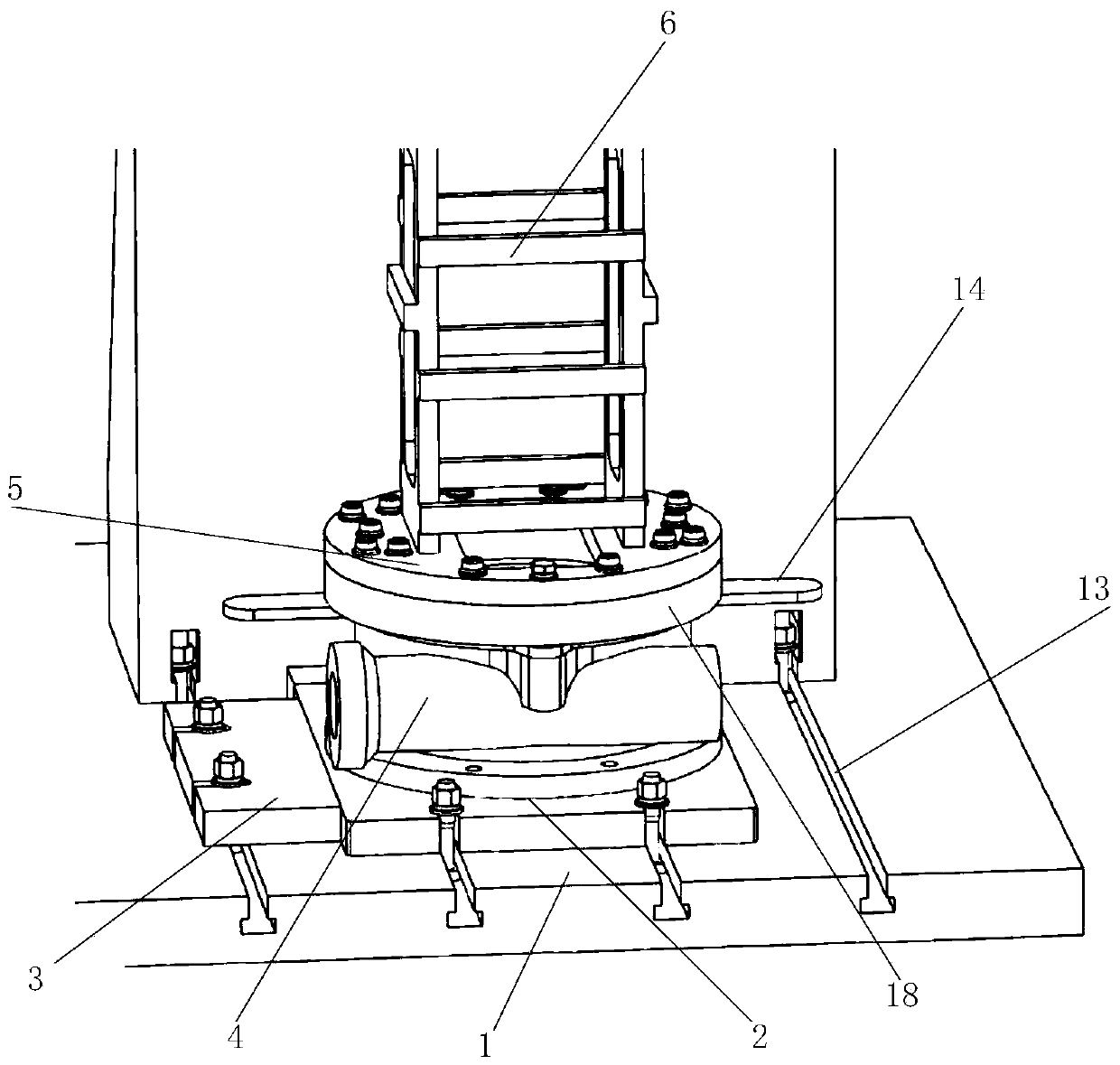

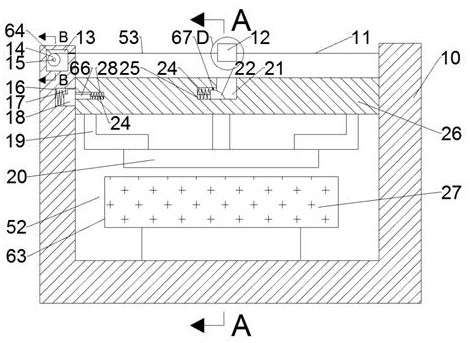

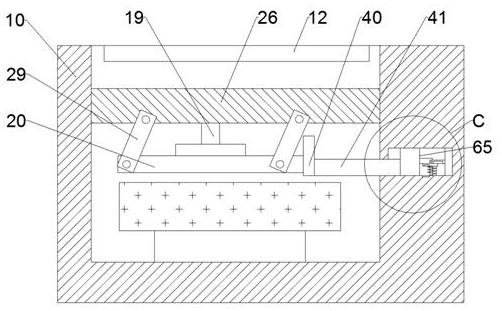

Spatial pose detection and adjustment method for engine case assembly

PendingCN112747672AReduce worker operationsImprove detection accuracy and assembly automationUsing optical meansComputer visionManufacturing quality

The invention discloses a spatial pose detection and adjustment method for engine case assembly, and belongs to the technical field of manufacturing quality prediction and control. The method comprises the following steps of: 1, carrying out regional division on an assembly surface of an engine case, and then driving a laser sensor to carry out data acquisition by utilizing a detection adjusting device; 2, fitting pose information of the end face of the engine case according to the collected data; and 3, judging whether the pose of the case meets the assembly requirement or not, if so, ending the process, and if not, giving offset information, adjusting the pose of the engine case by the detection and adjustment device, and returning to the step 1 for re-detection and re-adjustment. An indirect measurement mode is adopted, the parallelism of the end face and the datum plane is judged by measuring the distance between the flange end face of the engine case and the datum plane, and the automation degree and the measurement efficiency of the detection link can be improved.

Owner:BEIJING POWER MACHINERY INST +1

Method for packaging metal coated fiber grating

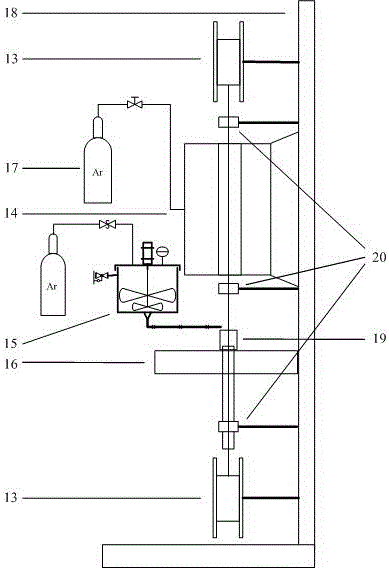

InactiveCN106568465AImprove radiation resistance and mechanical strengthGuaranteed bonding strengthMitigation of undesired influencesOperating temperature rangeIntegrated devices

The invention discloses a method for packaging metal coated fiber grating. A sleeving-binding-forming integrated device is employed, an internal diameter-variable stainless steel pipe (1) is used as a packaging sleeve, grating bared fiber is stored in the part with small diameter (3), and a bonding agent is filled in the part with large diameter (3). Volatile liquid stirring glass powder serves as the bonding agent, and the bonding agent is filled in the two ends of a sleeve through a high pressure extrusion means, and melted and cured under inert gas protection atmosphere, thereby preventing metal oxidation. A metal sleeve is used for packing fiber grating to improve the mechanical strength and radiation-prevention capability. Glass powder is used as a bonding agent to ensure reliability and stability of the packaging effect. The working temperature range is expanded, and the working service life is prolonged.

Owner:北京玻璃研究院有限公司

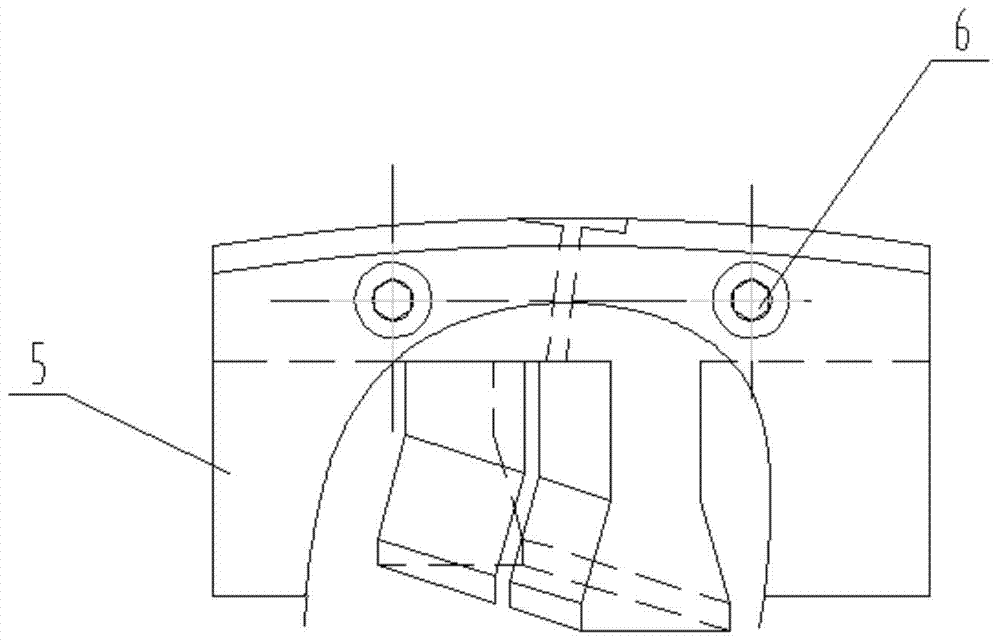

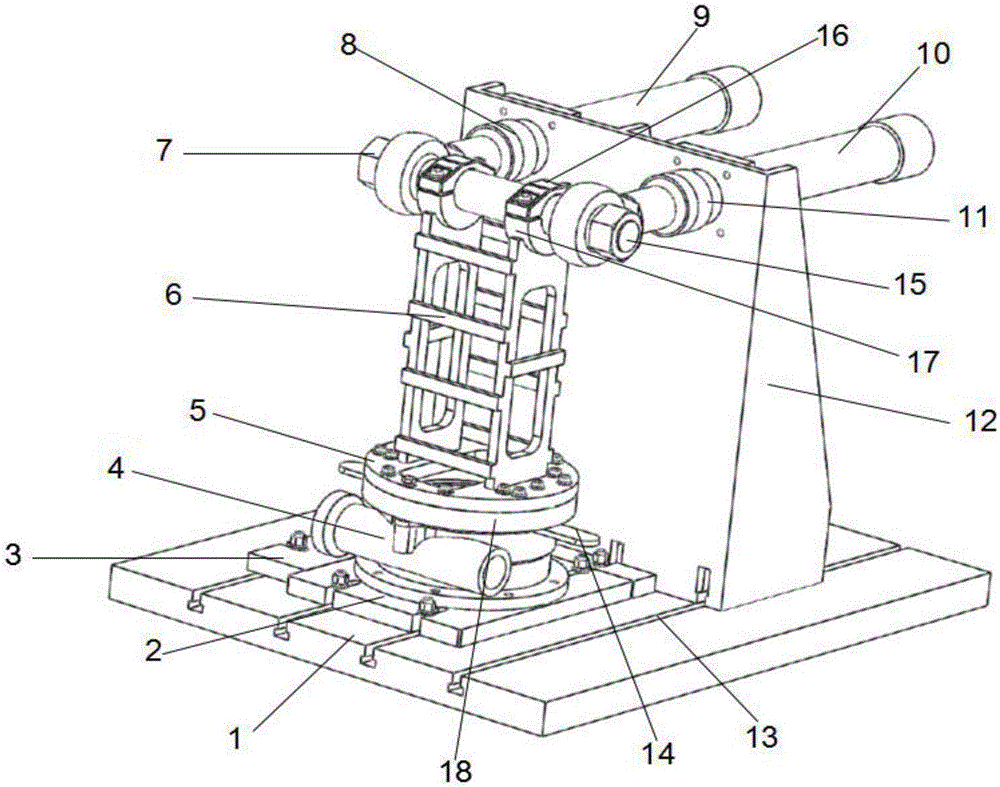

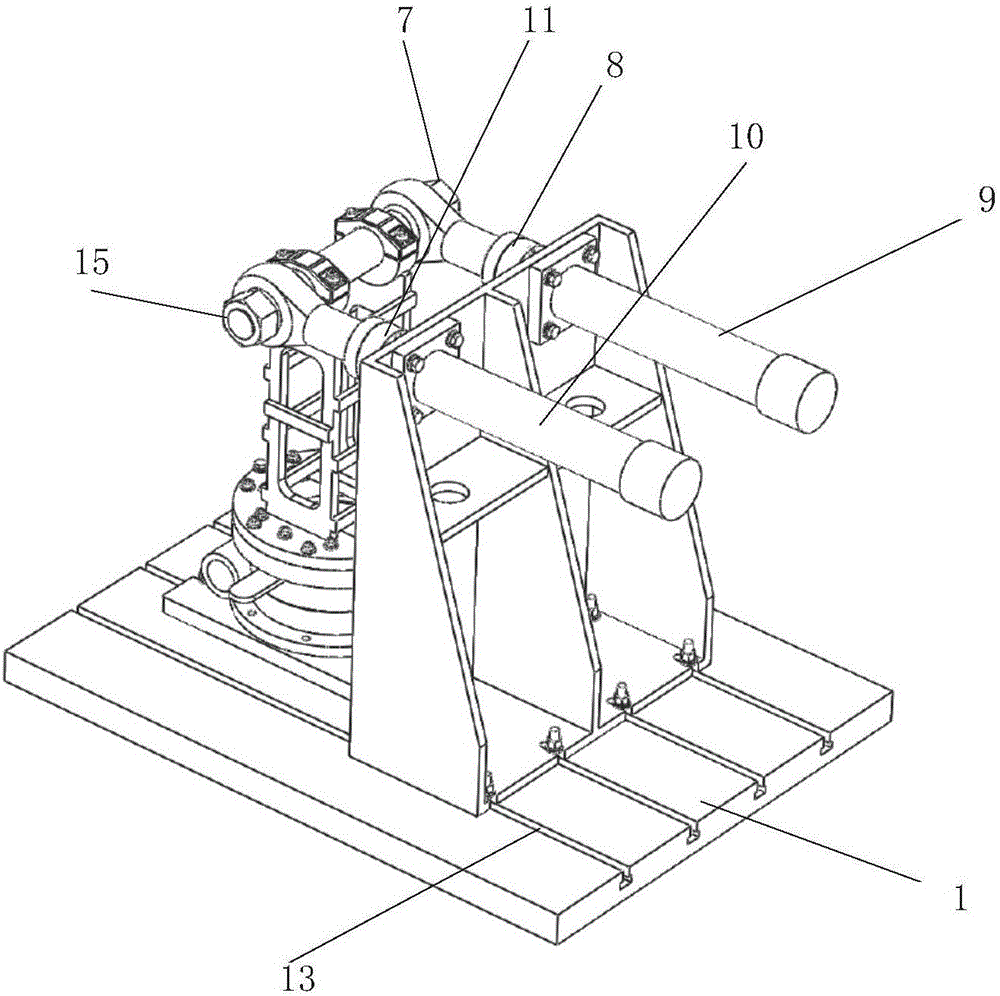

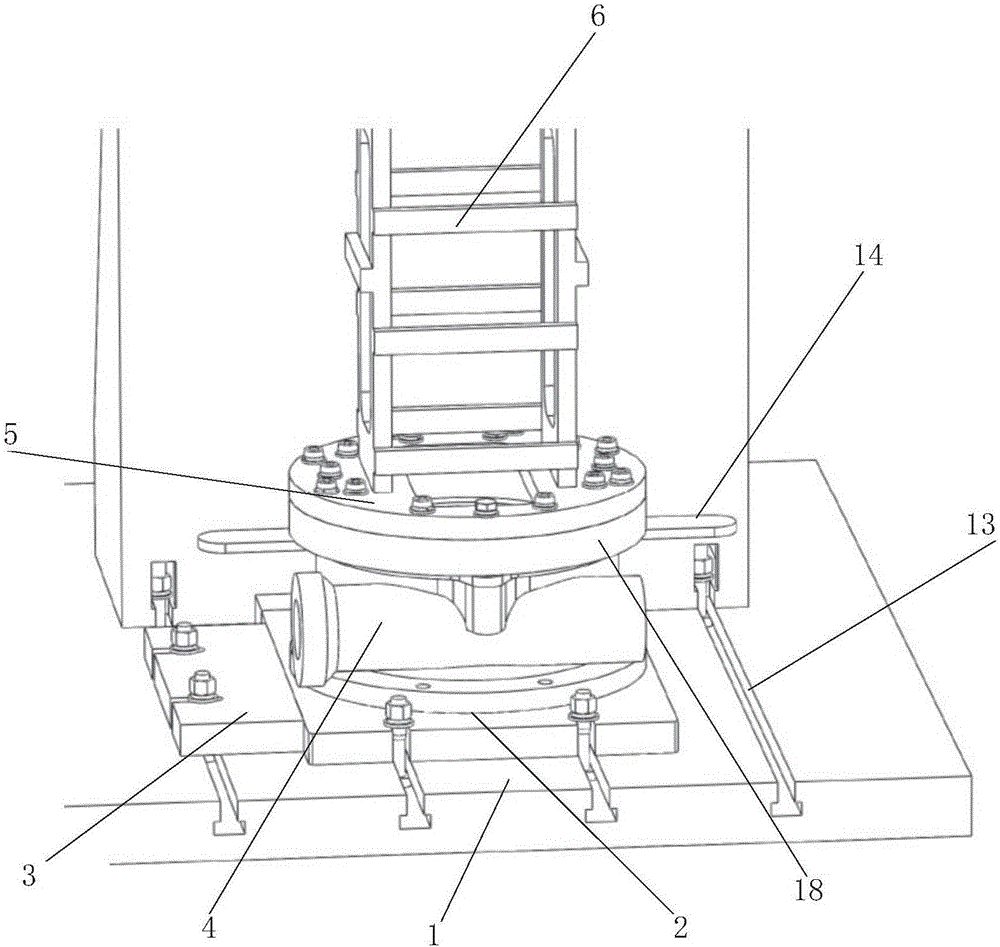

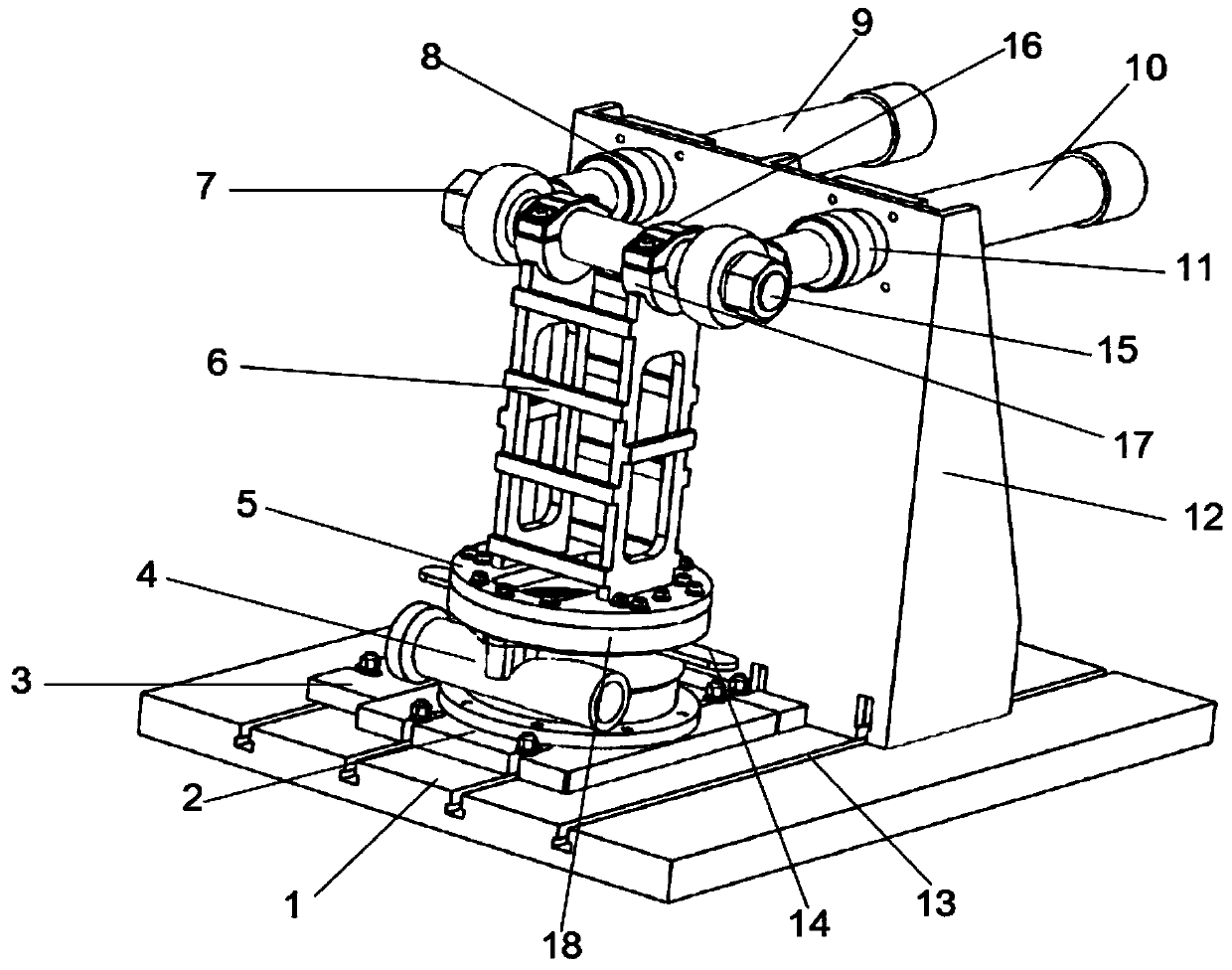

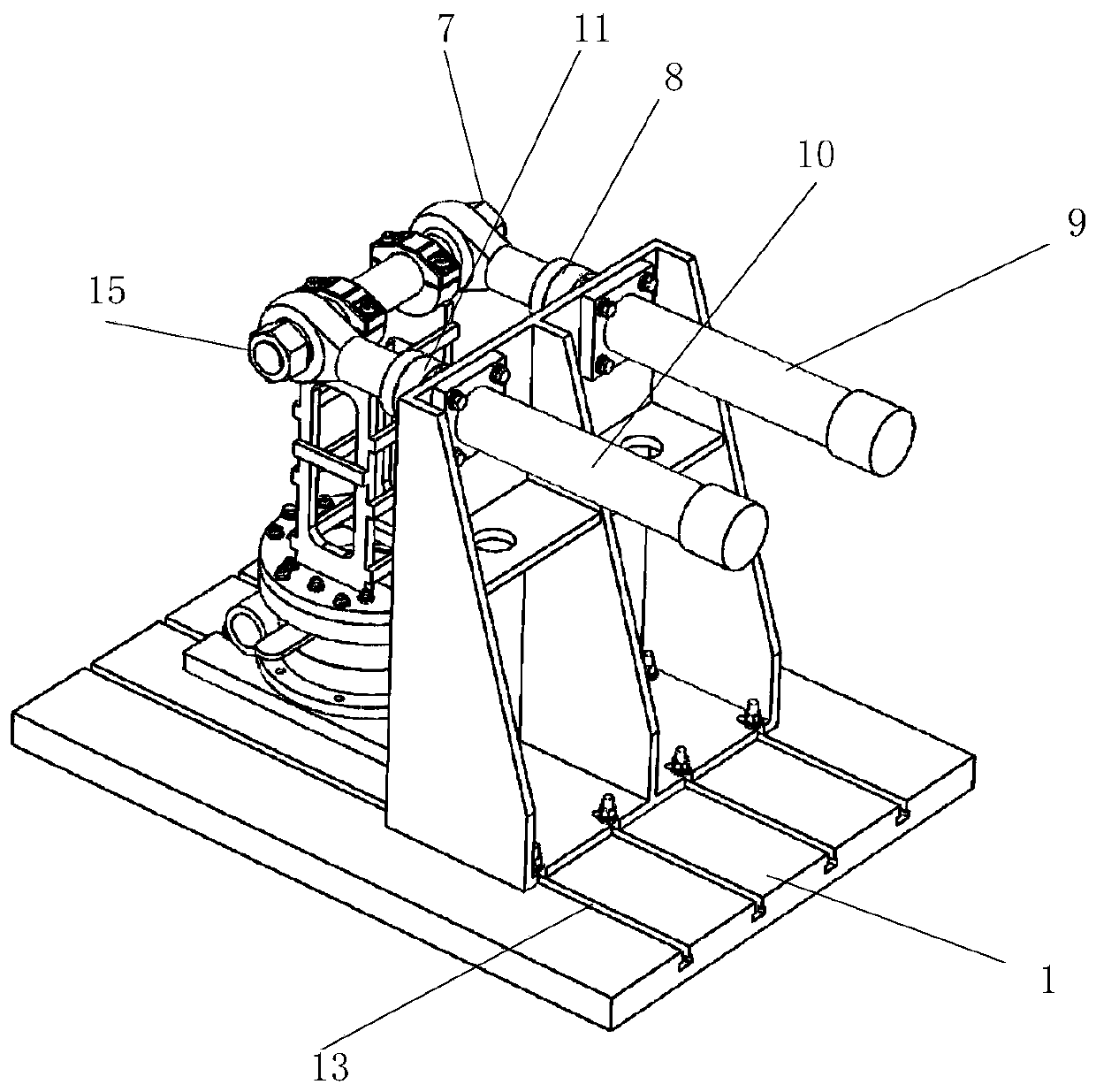

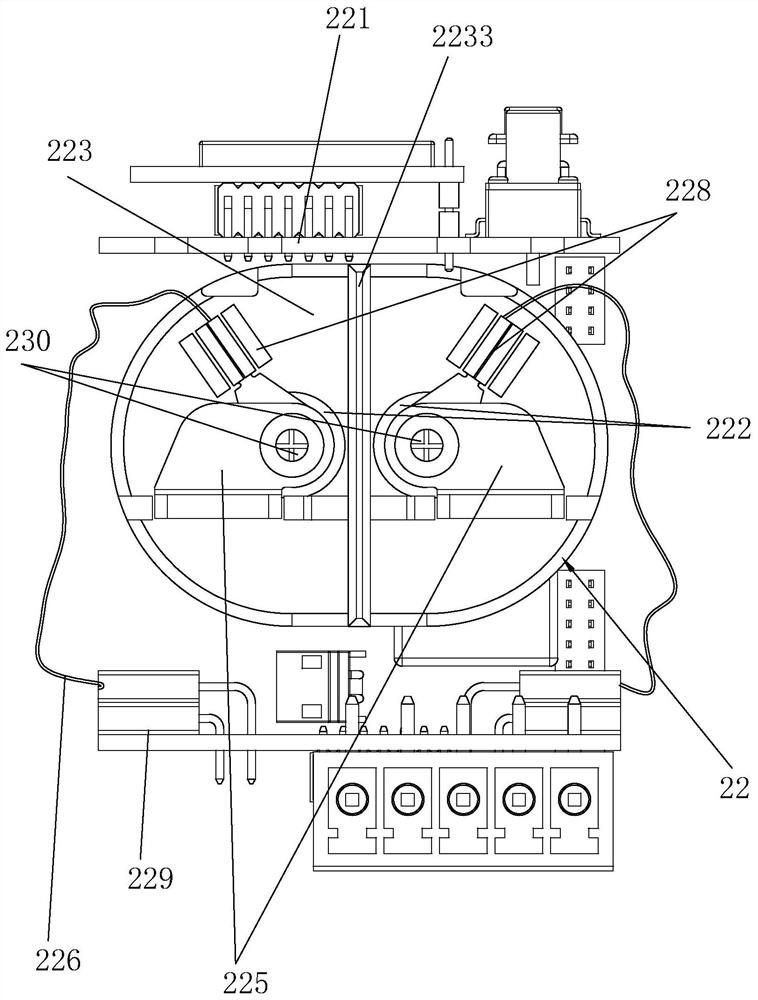

Device for detecting rigidity of gyration reduction gear

ActiveCN106840650AImprove rigidityHigh degree of automationMachine gearing/transmission testingGyrationEngineering

The invention discloses a device for detecting rigidity of a gyration reduction gear. The device includes a foundation base, a connection base, a first driving mechanism, a second driving mechanism, a displacement testing device and a control center; the connection base includes a connection-base bottom base, a connection-base support column, a first actuating arm and a second actuating arm, wherein the first actuating arm and the second actuating arm transversely stretch out from two opposite sides of the top of the connection-base support column; the first driving mechanism includes a first driving part and a first retractable part, and a first force sensor is arranged on the joint between a free end of the first retractable part and the first actuating arm; the second driving mechanism includes a second driving part and a second retractable part, and a second force sensor is arranged on the joint between a free end of the second retractable part and the second actuating arm; the displacement testing device is used for testing displacement values of the tested gyration reduction gear under the effect of a testing load; the control center is in communication connection with the first driving mechanism, the second driving mechanism, the first force sensor, the second force sensor and the displacement testing device. According to the device for detecting the rigidity of the gyration reduction gear, the torsional rigidity of the gyration reduction gear and the flexible rigidity of the gyration reduction gear can be tested mechanically.

Owner:ZHEJIANG SUPCON SOLAR TECHNOLOGY CO LTD

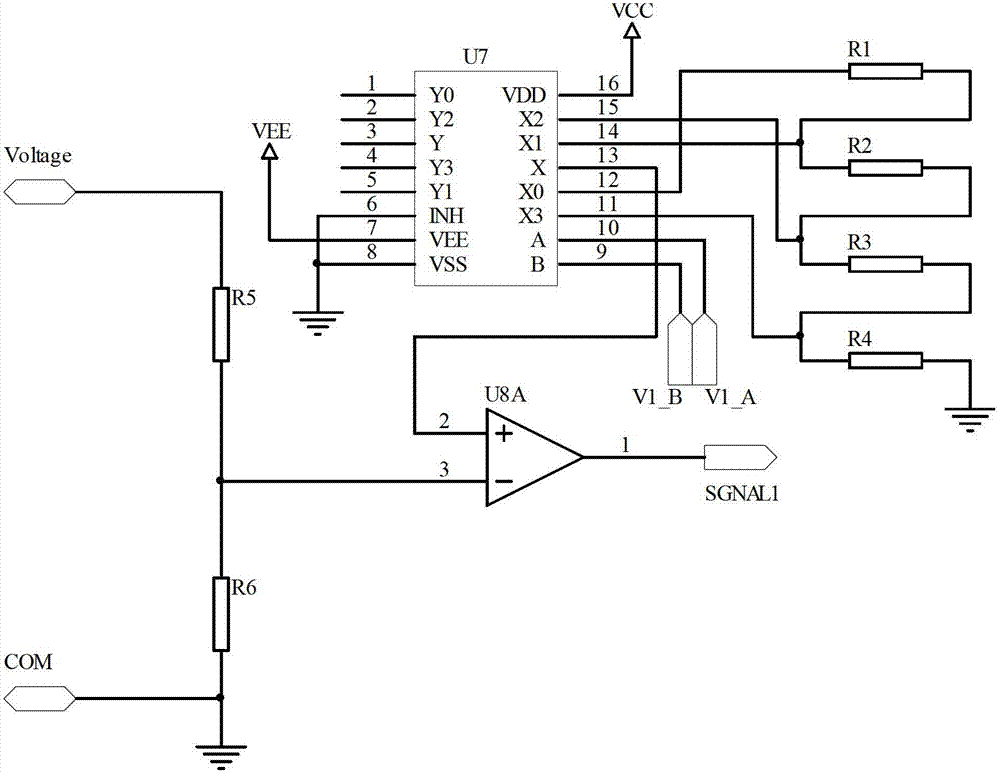

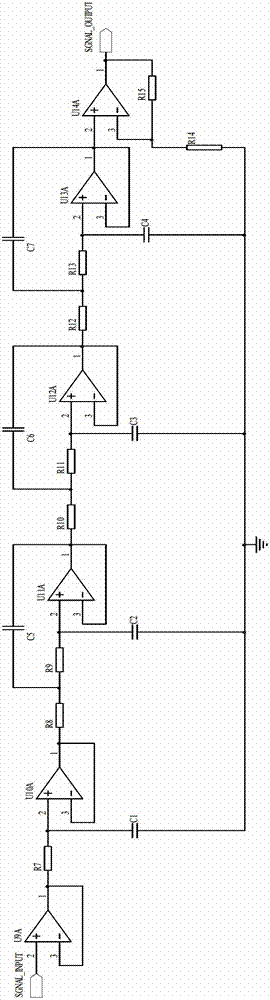

Testing method and device of harmonic wave universal meter

InactiveCN102759646ATo achieve the purpose of measurementAccurate measurementSpectral/fourier analysisMulti-tester circuitsSignal conditioning circuitsFunctional testing

The invention discloses a testing method of a harmonic wave universal meter. The testing method of the harmonic wave universal meter is characterized by comprising the following steps: (1) arranging a universal meter body, and arranging a functional circuit board in the universal meter body; (2) arranging a functional testing unit, a central processing unit and a power supply unit which are connected mutually on the functional circuit board; (3) arranging a signal conditioning circuit, a universal meter testing circuit and a harmonic wave testing circuit which are connected mutually in the functional testing unit; (4) arranging a software control platform in the central processing unit; and (5) powering on so as to enable the universal meter to operate. The invention also discloses a device for implementing the method. According to the invention, the universal meter and a harmonic wave analyzing meter are integrated into a whole, thus the testing is more convenient and rapid, and the harmonic wave universal meter is convenient to carry. By combining with the additional function disclosed by the invention, the harmonic wave universal meter is more intelligent to use, and the testing accuracy is improved greatly.

Owner:UNI TREND TECH (CHINA) CO LTD

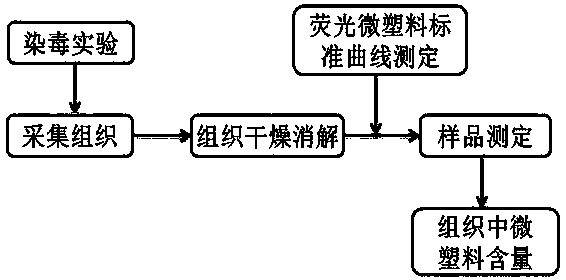

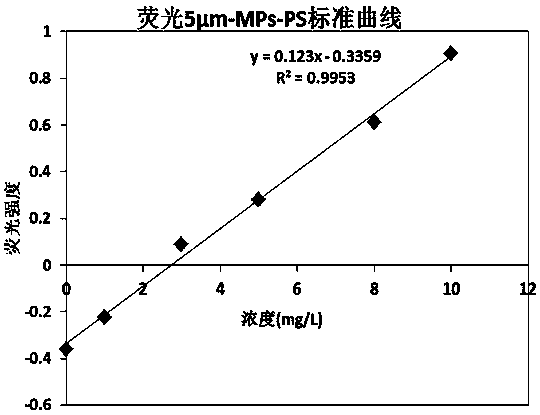

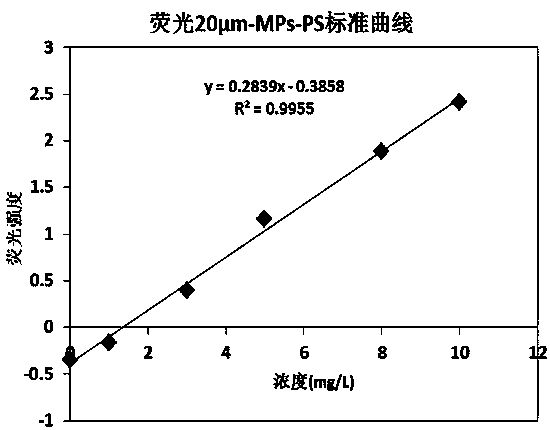

A method for quantitative analysis of the enrichment and distribution of microplastics in aquatic organisms

ActiveCN105651748BQuantitatively effectiveQuantitative analysis is validFluorescence/phosphorescenceBiological bodyDecomposition

Owner:NANJING UNIV

A rigidity detection device for a rotary reducer

ActiveCN106840650BImprove rigidityHigh degree of automationMachine part testingControl engineeringStructural engineering

Owner:ZHEJIANG SUPCON SOLAR TECHNOLOGY CO LTD

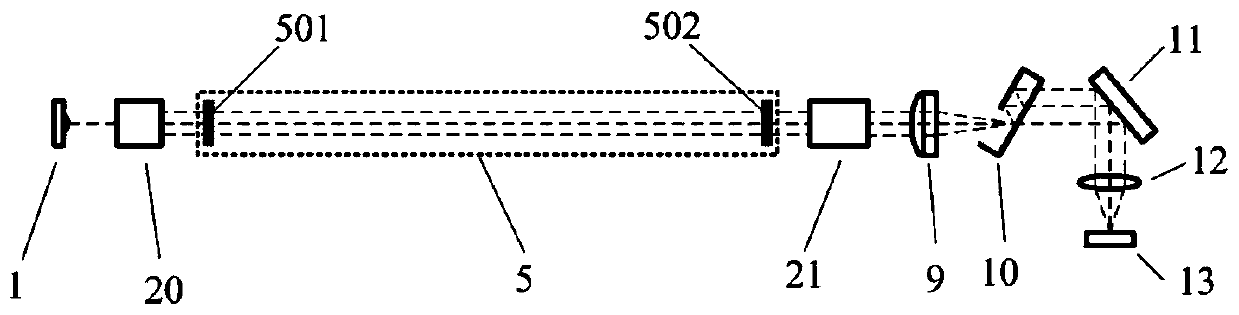

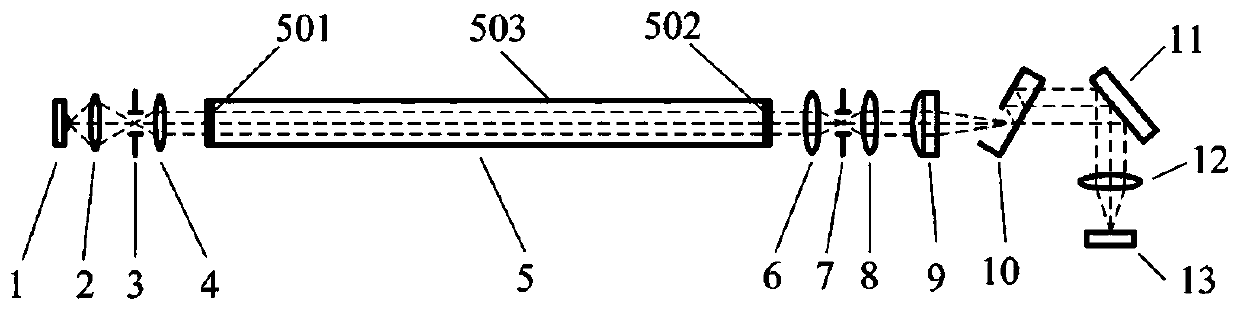

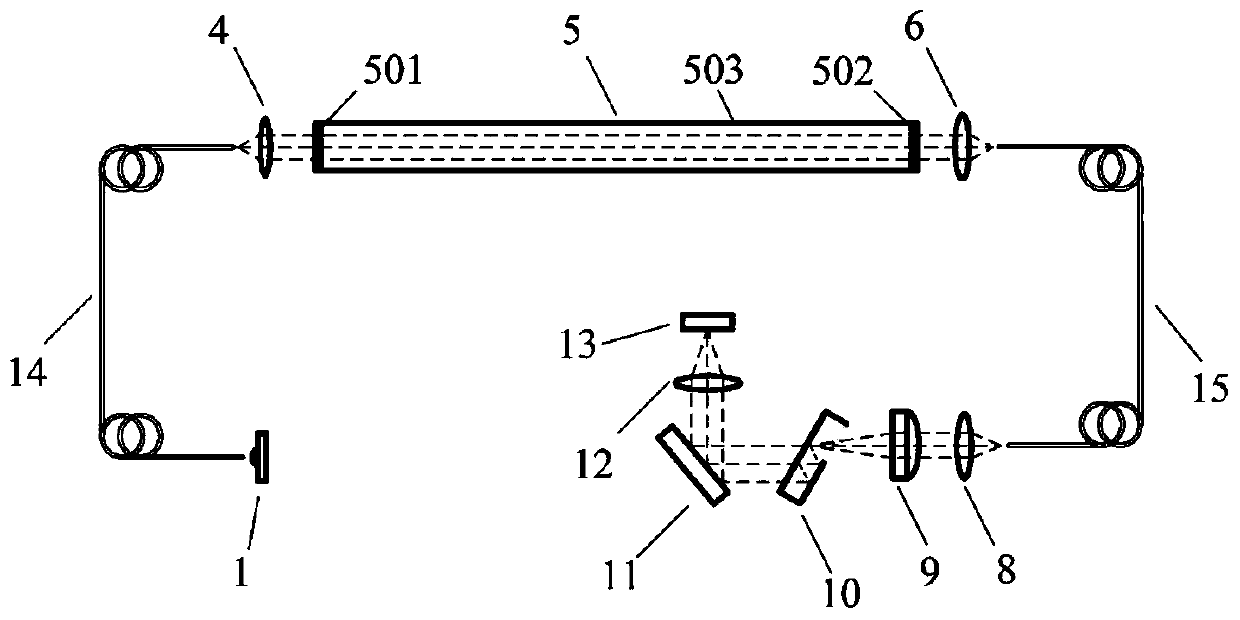

Broadband cavity enhanced apparatus

PendingCN110596026AHigh-resolutionTo achieve the purpose of measurementColor/spectral properties measurementsGratingImaging lens

The present invention discloses a broadband cavity enhanced apparatus. The apparatus comprises a broadband light source (1), an optical resonator (5), a collimation part (21), a cylindrical lens (9) and a detector that are optically connected. The detector is a flat etalon (10), a blazed grating (11), an imaging lens (12) and a CCD target surface (13) that are successively optically connected. Anincluded angle between the flat etalon (10) and an optical axis output by the collimation part (21) is 1 to 20 degrees. Further, a flat back surface (1003) of the flat etalon (10) is located on a focal plane of the cylindrical lens (9). A flat front surface incident window (1001) of the flat etalon (10) is coated with an antireflection film. The flat front surface (1002) and the flat back surface(1003) are coated with a reflecting film. The imaging lens (12) is located at a first-order diffraction light image of the blazed grating (11). The CCD target surface (13) is a two-dimensional area-array target surface located at an image of the imaging lens (12). The apparatus can be used for simultaneously measuring more gas components, and can be widely used for atmospheric trace and aerosol optical property measurement.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

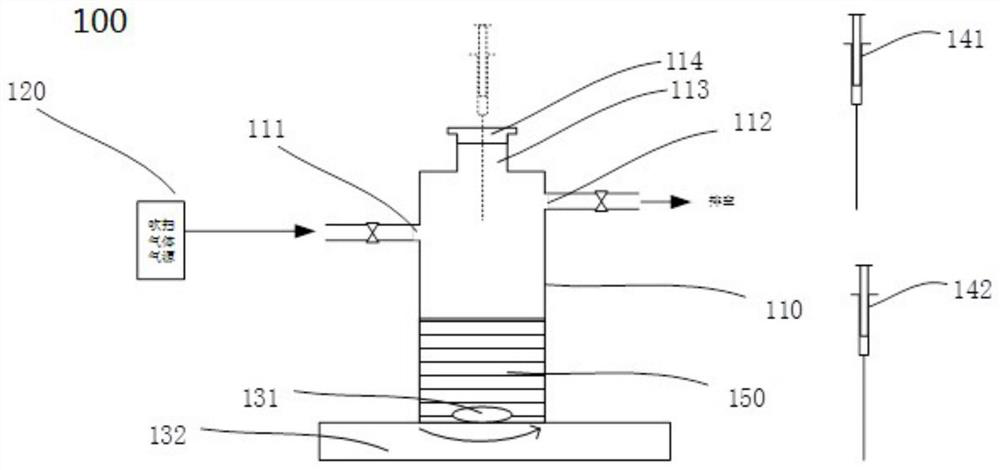

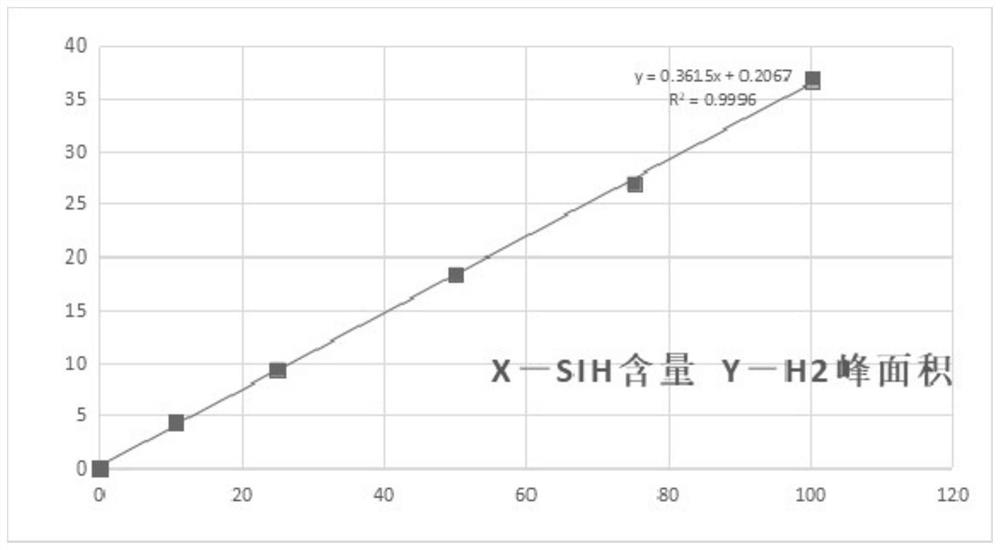

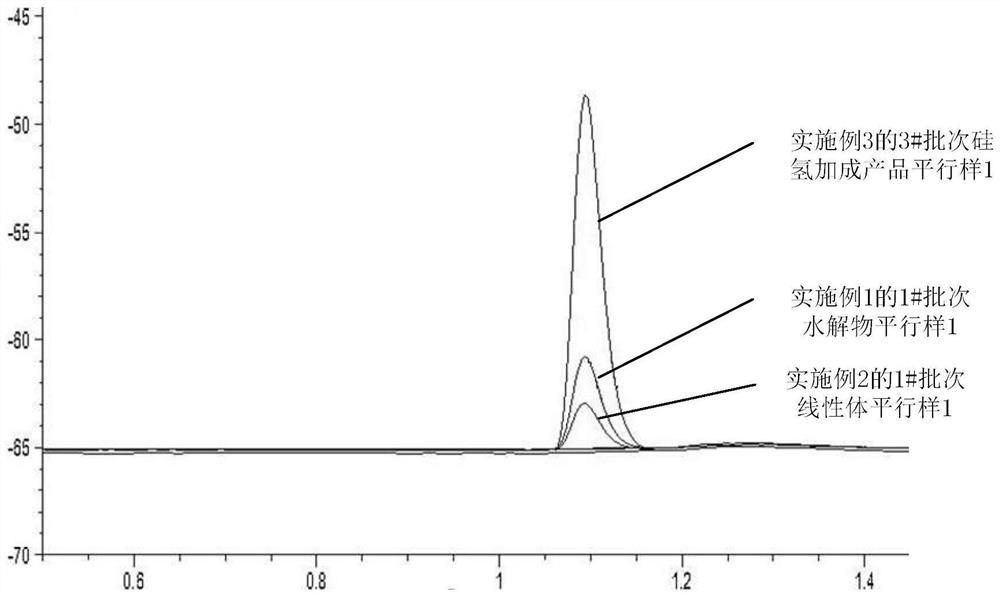

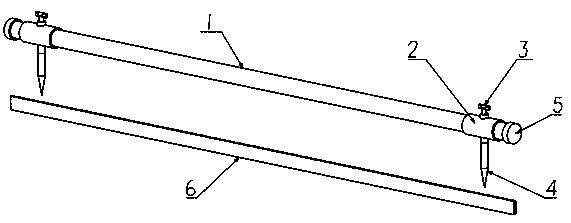

Device and method for quantitative determination of residual silicon hydrogen in organosilicon sample

PendingCN114113423ATo achieve the purpose of measurementReduce solubilityChemical analysis using catalysisComponent separationQuantitative determinationPhysical chemistry

The invention relates to a pretreatment device and method for quantitative determination of residual silicon hydrogen in an organic silicon sample. The pretreatment device comprises a silicon hydrogen reaction bottle, a sample introduction device, a sampling device, a stirring device and a gas purging device. According to the device provided by the invention, the gas purging device is arranged, so that reaction gas in the silicon-hydrogen reaction bottle can be replaced with inert gas, and the purpose of continuously measuring a plurality of samples is achieved; the method provided by the invention can be used for measuring the content of silicon and hydrogen in a micro-scale manner.

Owner:JIANGXI BLUESTAR XINGHUO SILICONE CO LTD

Adjustable opening measuring scale

PendingCN110726352AGuaranteed coincidenceRealize flexible splicingMechanical measuring arrangementsEngineeringMeasuring ruler

Owner:FAW CAR CO LTD

Pressure sensor protection device capable of eliminating impact force

InactiveCN112113652AAvoid direct damageSimple structureOscillations damping for weighingEngineeringImpact

The invention discloses a pressure sensor protection device capable of eliminating the impact force. The device comprises a buffer base, a measuring cavity with an upward opening is formed in the upper end face of the buffer base, and a buffer cavity is formed in the left side of the upper end of the buffer base. The device is simple in structure and convenient to operate, overcomes large error interference on measurement caused by impact force of an object during manual measurement, meanwhile, can avoid the phenomenon that the pressure sensor is directly damaged due to large impact force, andhas a certain economic effect, and can make measurement more convenient; and when the device is used, impact kinetic energy of an object can be eliminated when the object falls into the space betweenthe pressure sensors, then constraint on the object is automatically eliminated, and the object acts on the sensors to achieve the measurement purpose, so that measurement can be completed more quickly and accurately, and meanwhile, the phenomenon that the sensors are directly damaged due to large impact force can be avoided; and the device has a certain economic effect.

Owner:绍兴航雨智能科技有限公司

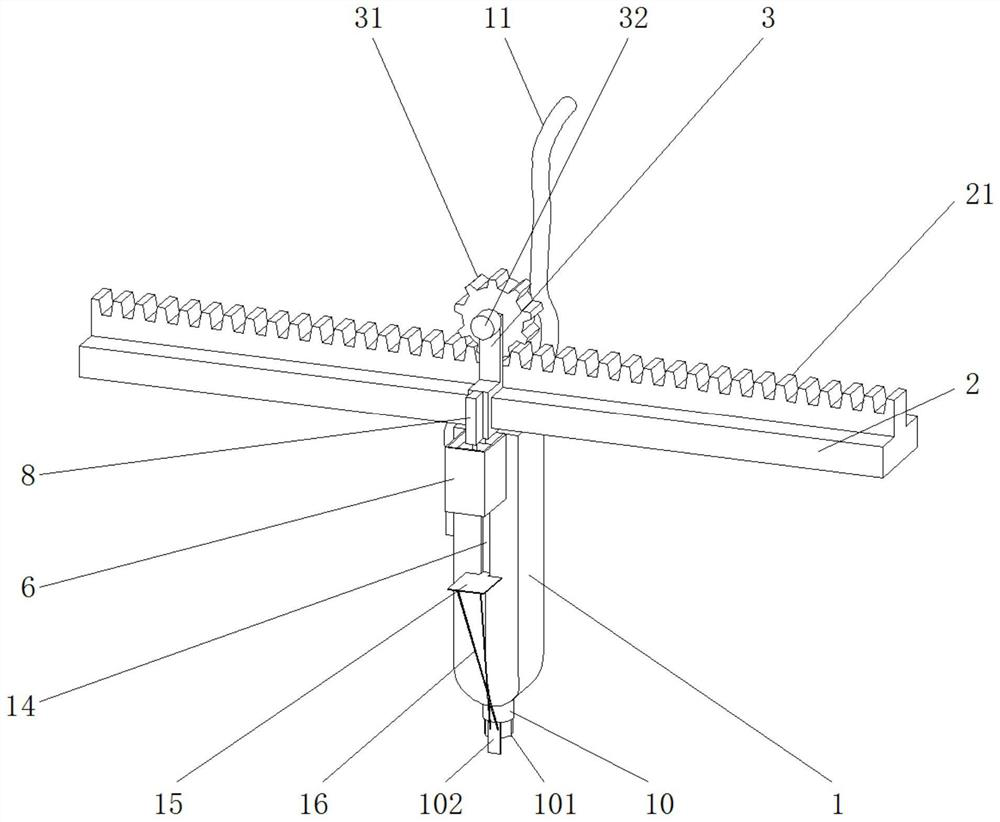

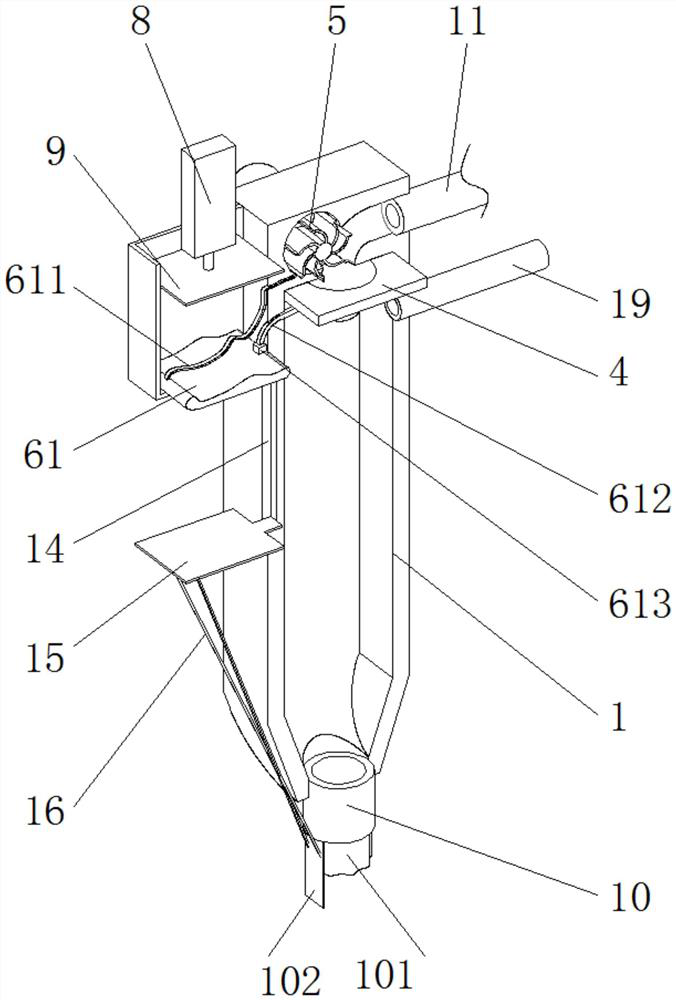

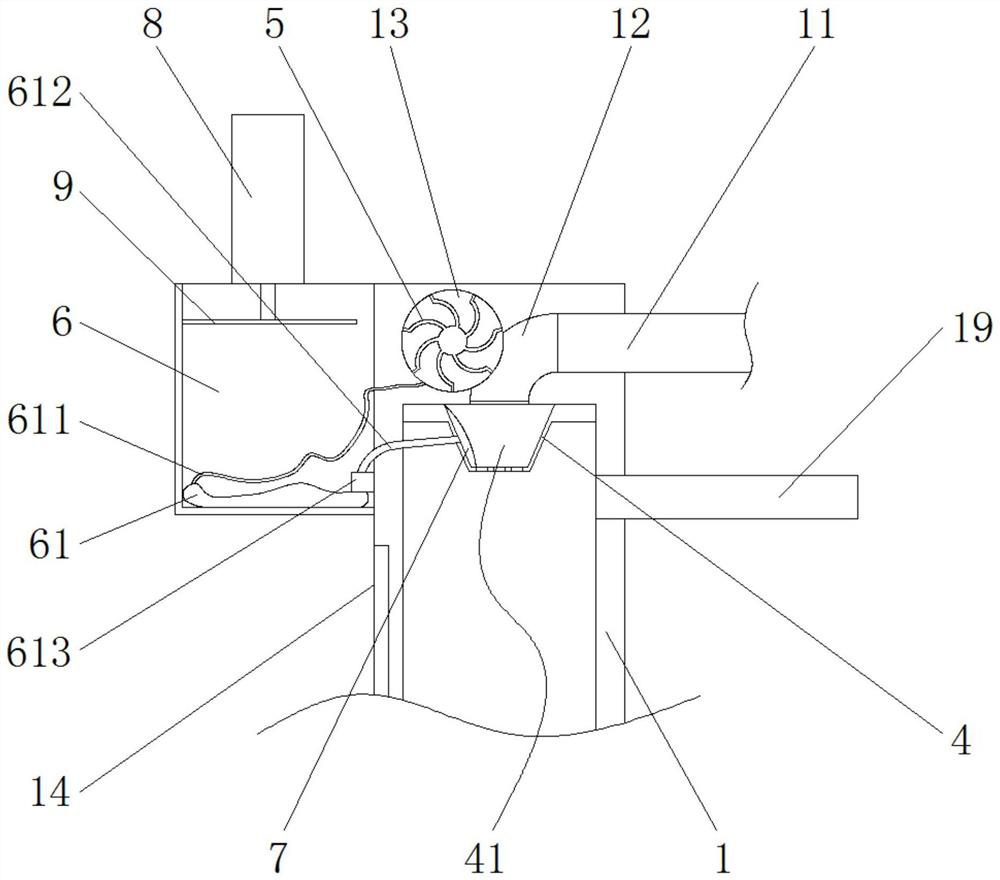

A conveying and metering device for powder auxiliaries used in the printing and dyeing industry

ActiveCN113086648BControl displacementTo achieve the purpose of measurementVolume measurement apparatus/methodsBulk conveyorsProcess engineeringMechanical engineering

The invention provides a conveying and metering device for powder auxiliaries used in the printing and dyeing industry, which relates to the field of printing and dyeing equipment. It includes an injection chamber, the back of the injection chamber is welded with an air pipe, an air guide groove is opened inside the injection chamber, and the air pipe is communicated with the air guide groove. The printing and dyeing industry uses a conveying and metering device for powder auxiliaries, which uses air to drive the fan to rotate, so that the pointer rotates through the grating to achieve the purpose of metering. As soon as the magnet is driven down by the electric push rod, it squeezes the air bag and attracts the second magnet to rise. Thereby, the air in the air bag is pressed into the air bag, so that the air bag expands and blocks the leakage hole of the isolation plate. At the same time, the second magnet pulls the string to shrink the cloth and seal the nozzle opening. In this way, the sealing effect is achieved, which plays a role in controlling the displacement of powder additives. It replaces traditional manual measurement, improves work efficiency, and further improves measurement accuracy.

Owner:SHAOXING HUAXIN AUTOMATION DEVICE

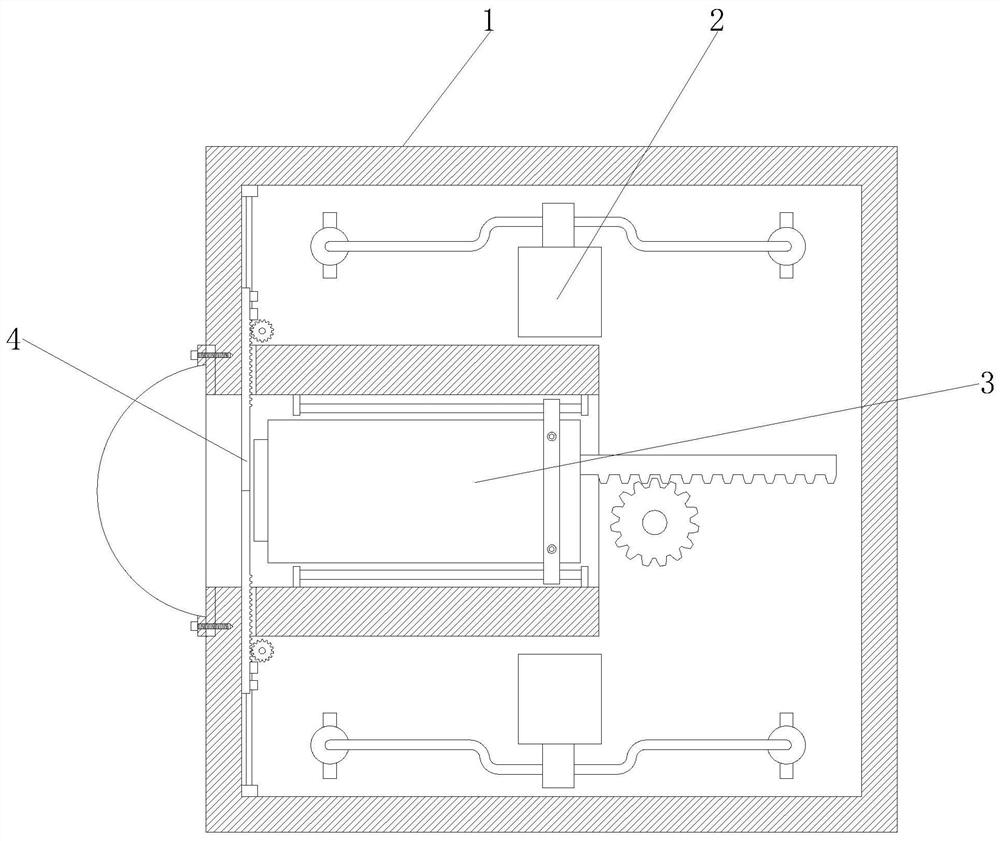

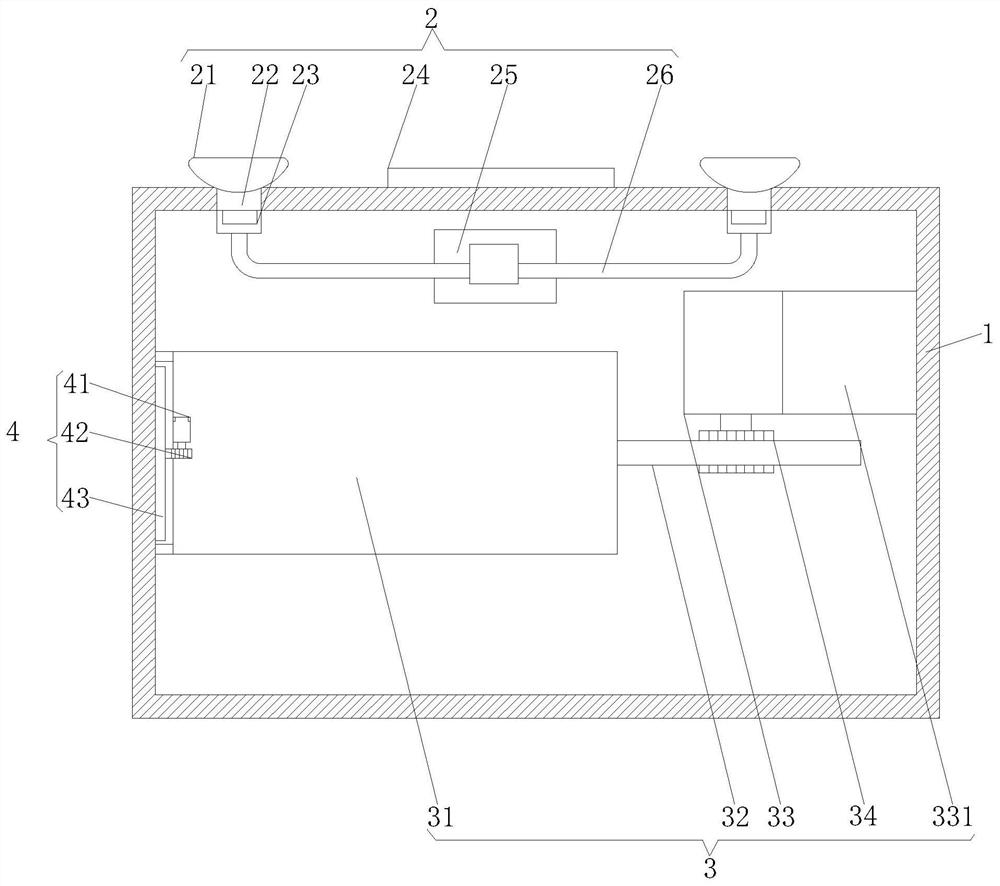

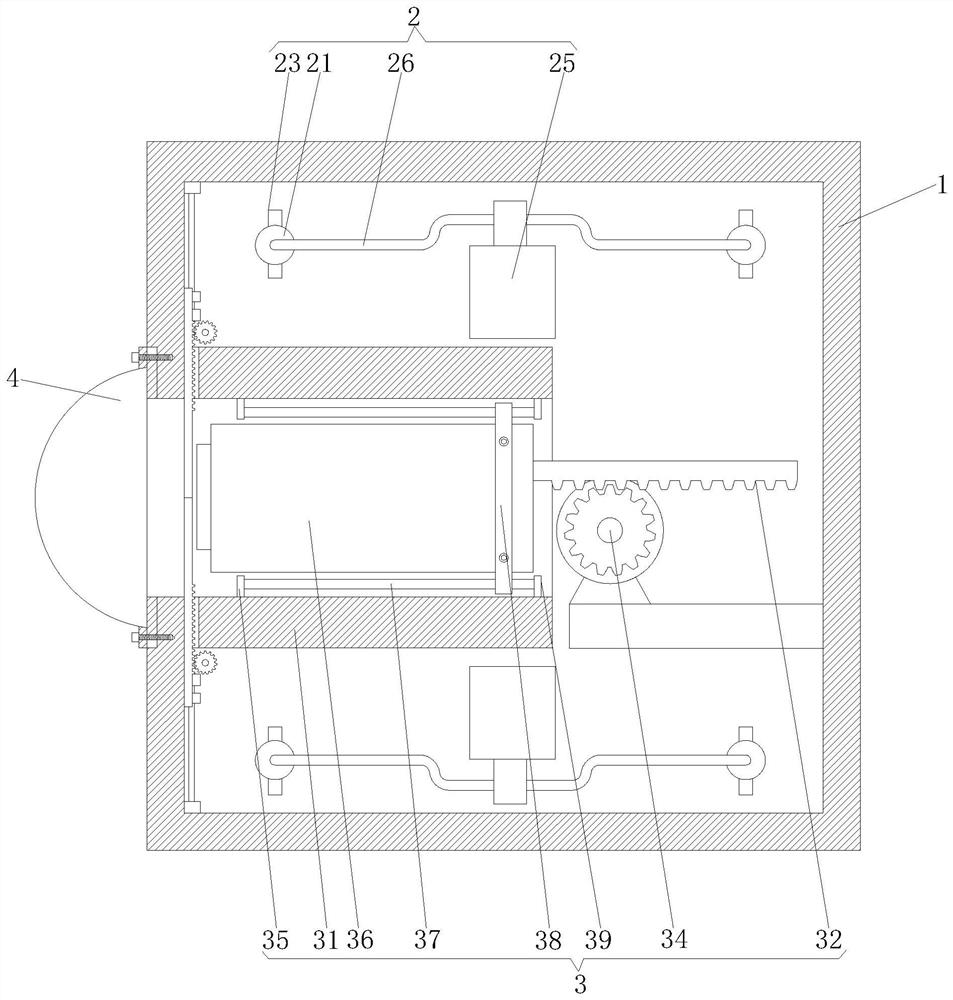

A measuring device for opening and closing speed of UHV vacuum circuit breaker

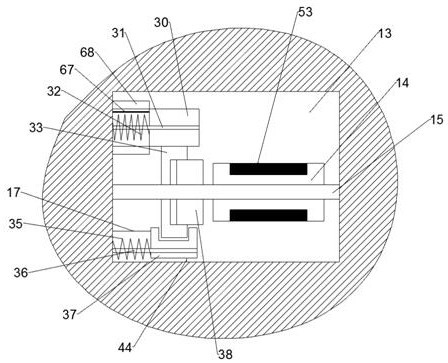

ActiveCN112305414BReach initial protectionTo achieve the purpose of measurementMachine part testingCircuit interrupters testingMotor driveGear wheel

The invention discloses an opening and closing speed measuring device for an UHV vacuum circuit breaker. The inner wall of the middle part on the left side of the casing is fixedly connected to the left side of the measuring mechanism, and a protection mechanism is arranged in the casing near the left side of the measuring mechanism. The left side of the protection mechanism is fixedly connected to the left inner wall of the casing, and the inner rear side of the casing is close to the top and bottom of the measuring mechanism and fixedly connected to the rear side of the fixing mechanism. The opening and closing speed measuring device of the UHV vacuum circuit breaker, through the set measuring mechanism, can start the first motor to drive the gear to rotate during the measurement, so that the rack moves to the left, and then fits on the positioning rod through the fixing frame Stable sliding, the speed sensor can be pushed out of the fixed shell during measurement to achieve the purpose of measurement. After the measurement is completed, the first motor drives the gear to rotate in the opposite direction, and the rack moves to the right to drive the speed sensor to retract into the fixed shell, which can achieve good measurement results. At the same time, it can also achieve preliminary protection for the speed sensor.

Owner:亚太人民集团电力装备有限公司

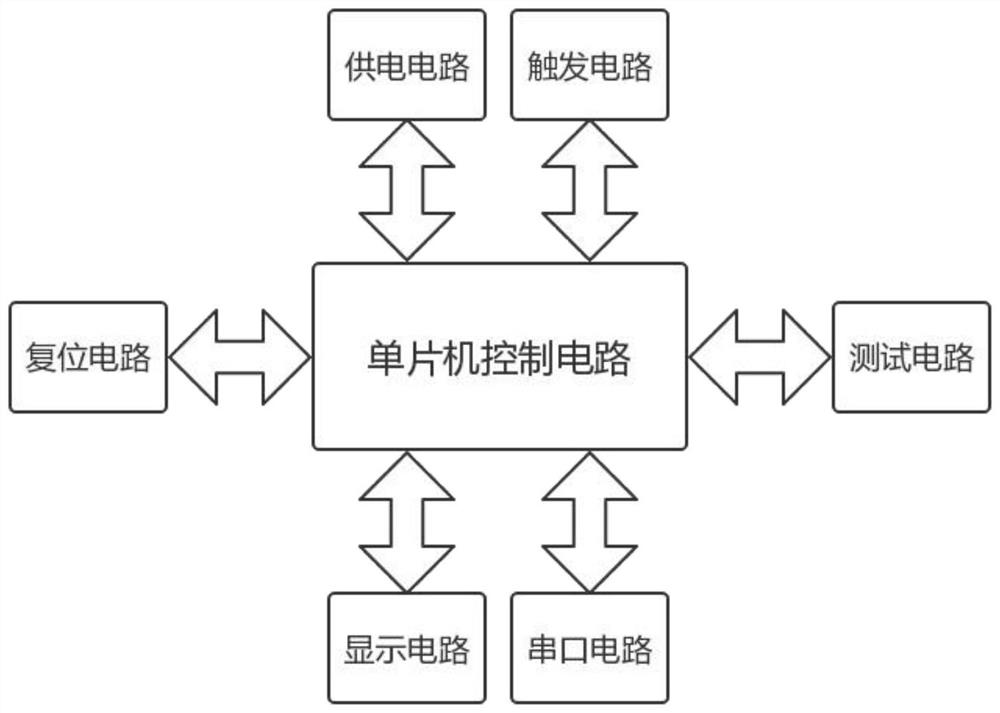

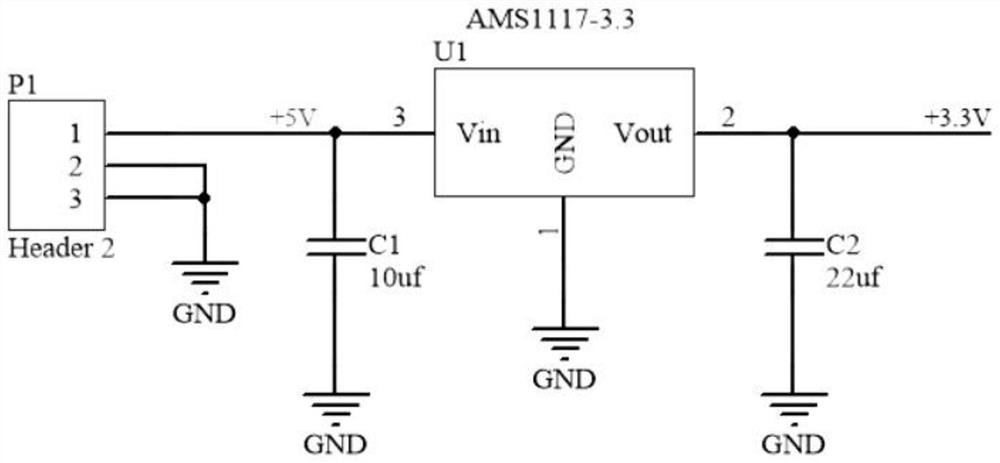

Temperature relay test board based on single-chip microcomputer and control method thereof

The invention belongs to the technical field of temperature relay detection, and discloses a single-chip microcomputer-based temperature relay test board and a control method thereof, and the single-chip microcomputer-based temperature relay test board comprises a single-chip microcomputer control circuit, a power supply circuit, a trigger circuit, a test circuit, a serial port circuit, a display circuit and a reset circuit. The power supply circuit is used for supplying power to the whole device; the trigger circuit is used for controlling detection of the temperature sensor and data transmission; the test circuit is used for collecting temperature data signals; the serial port circuit is used for sending collected temperature data signals to the single-chip microcomputer control circuit. The single-chip microcomputer control circuit is used for processing the temperature data signals. The circuit auxiliary device is simple in structure, easy to implement and low in manufacturing cost, the circuit auxiliary device is not provided with a temperature system and a data display system and can be connected with various temperature boxes and the data display system, an LCD display screen is designed in the circuit and can be directly matched with the temperature boxes to independently display test values, and the measurement purpose is achieved.

Owner:北京京瀚禹电子工程技术有限公司

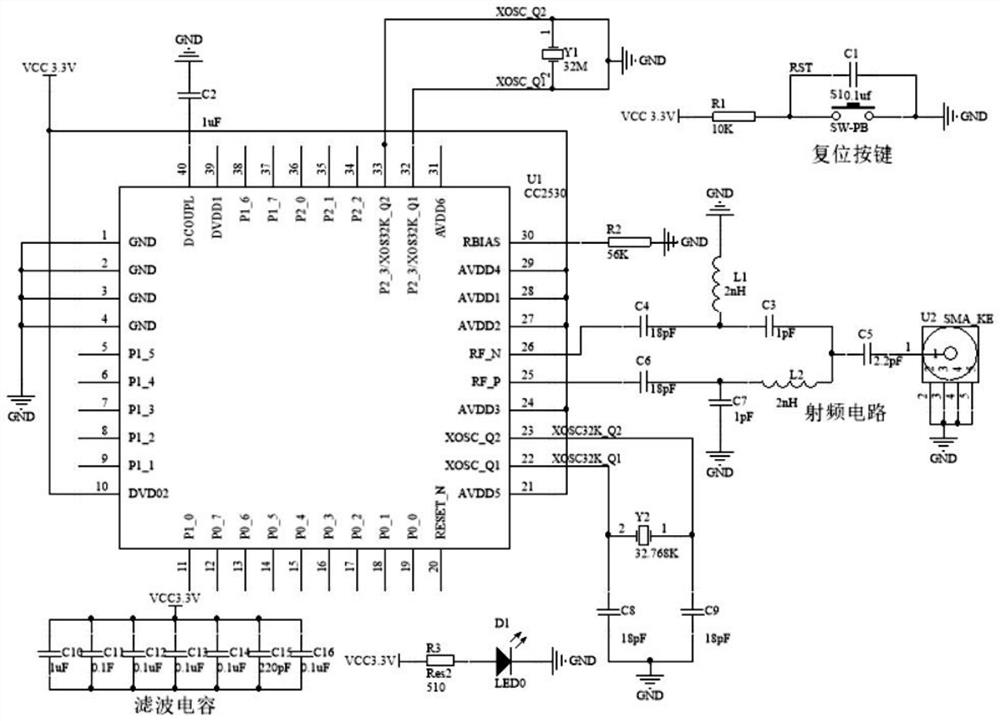

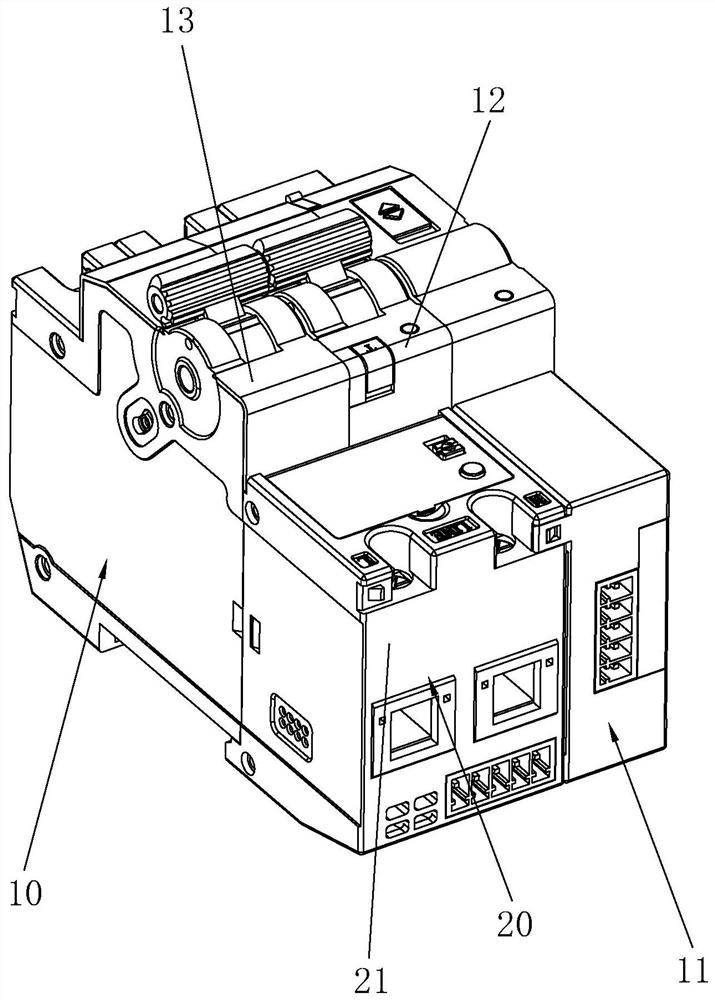

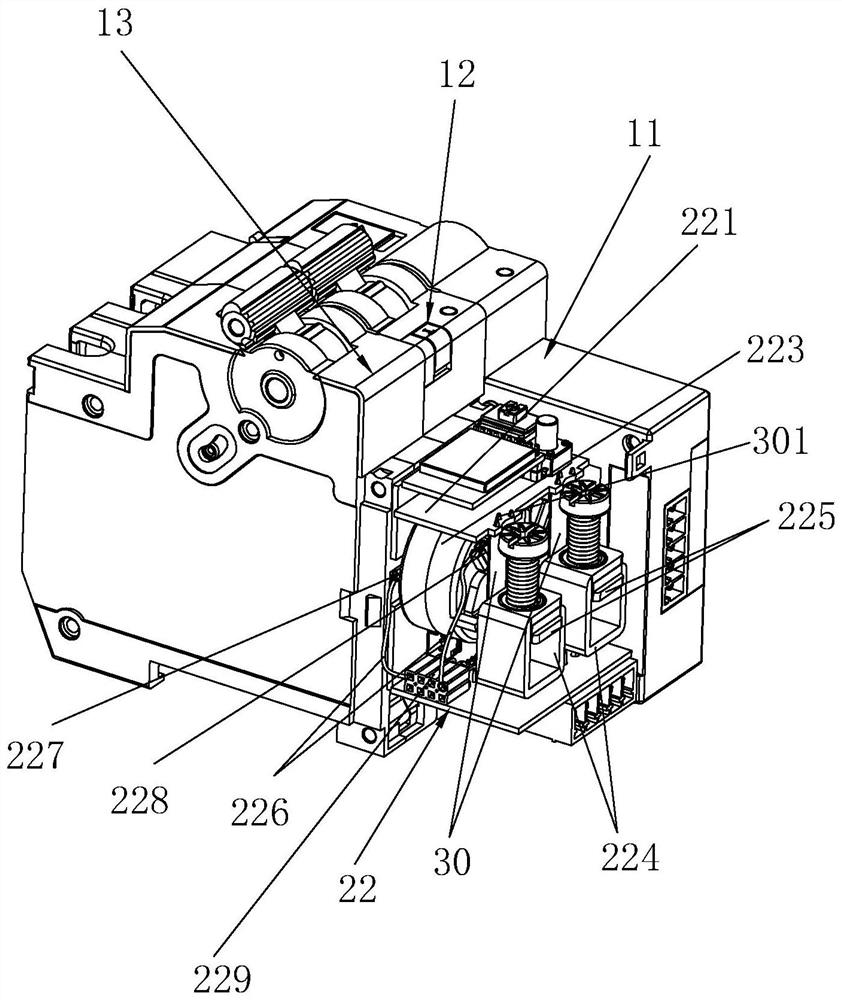

Automatic reclosing miniature circuit breaker

PendingCN113012993ASimple structureSimple structural designProtective switch operating/release mechanismsManganinRecloser

The invention relates to an automatic reclosing miniature circuit breaker. The miniature circuit breaker comprises a circuit breaker unit and an automatic reclosing device assembled with the circuit breaker unit, the circuit breaker unit comprises an N-line switch module, an L-line switch module and a leakage protection metering module, and the leakage protection metering module comprises a shell and a leakage protection metering assembly arranged in the shell. The electric leakage protection metering assembly comprises an electric leakage protection circuit board, two manganin steel conductive tubes, a zero sequence mutual inductor sleeved on the two manganin steel conductive tubes, two wiring terminals, and two conductive sheets respectively connected between the two wiring terminals and the two manganin steel conductive tubes. One ends of the two manganin steel conductive tubes are electrically connected with the N-line switch module and the L-line switch module respectively, and a lead is connected between each of the two ends of each manganin steel conductive tube and the leakage protection circuit. The miniature circuit breaker has the advantages of simple structure, stable and reliable performance, small volume, convenient assembly and low cost.

Owner:ZHEJIANG DELING SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com