Coaxiality detecting and adjusting method for cartridge receiver of aero-engine

A technology of aero-engine and adjustment method, which is applied to measuring devices, instruments, etc., can solve problems such as low detection efficiency, and achieve the effects of simplifying manual meter loading, reducing worker operations, and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

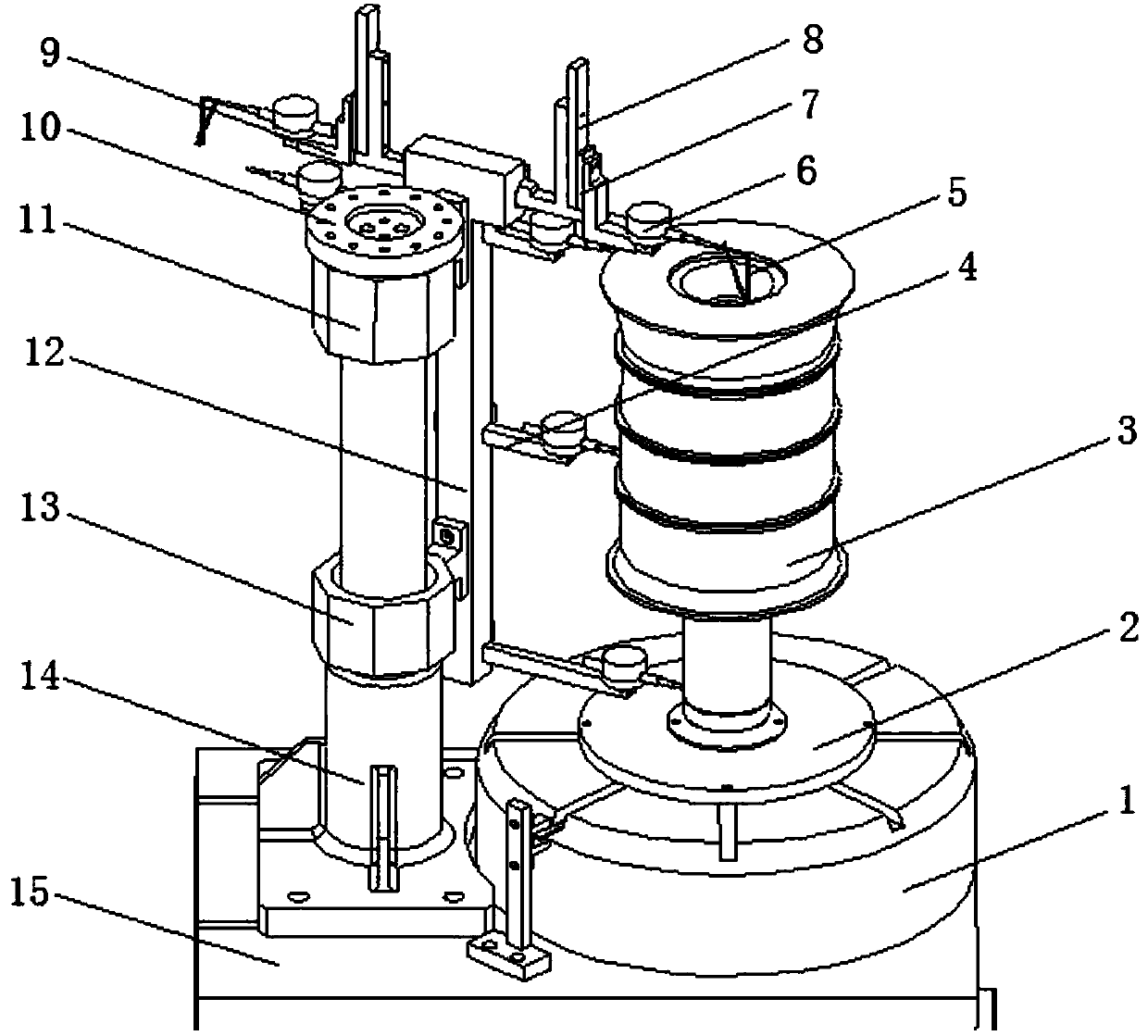

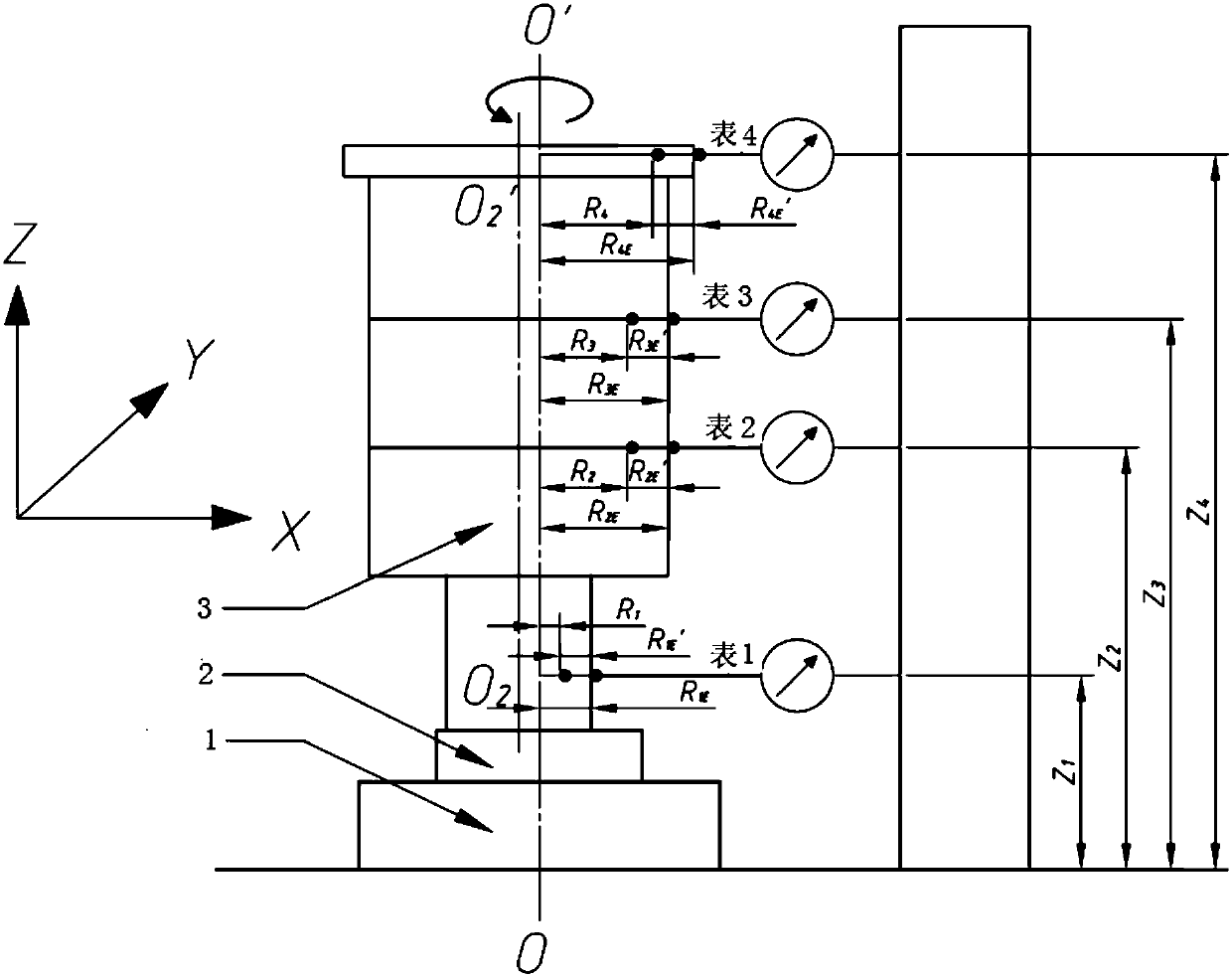

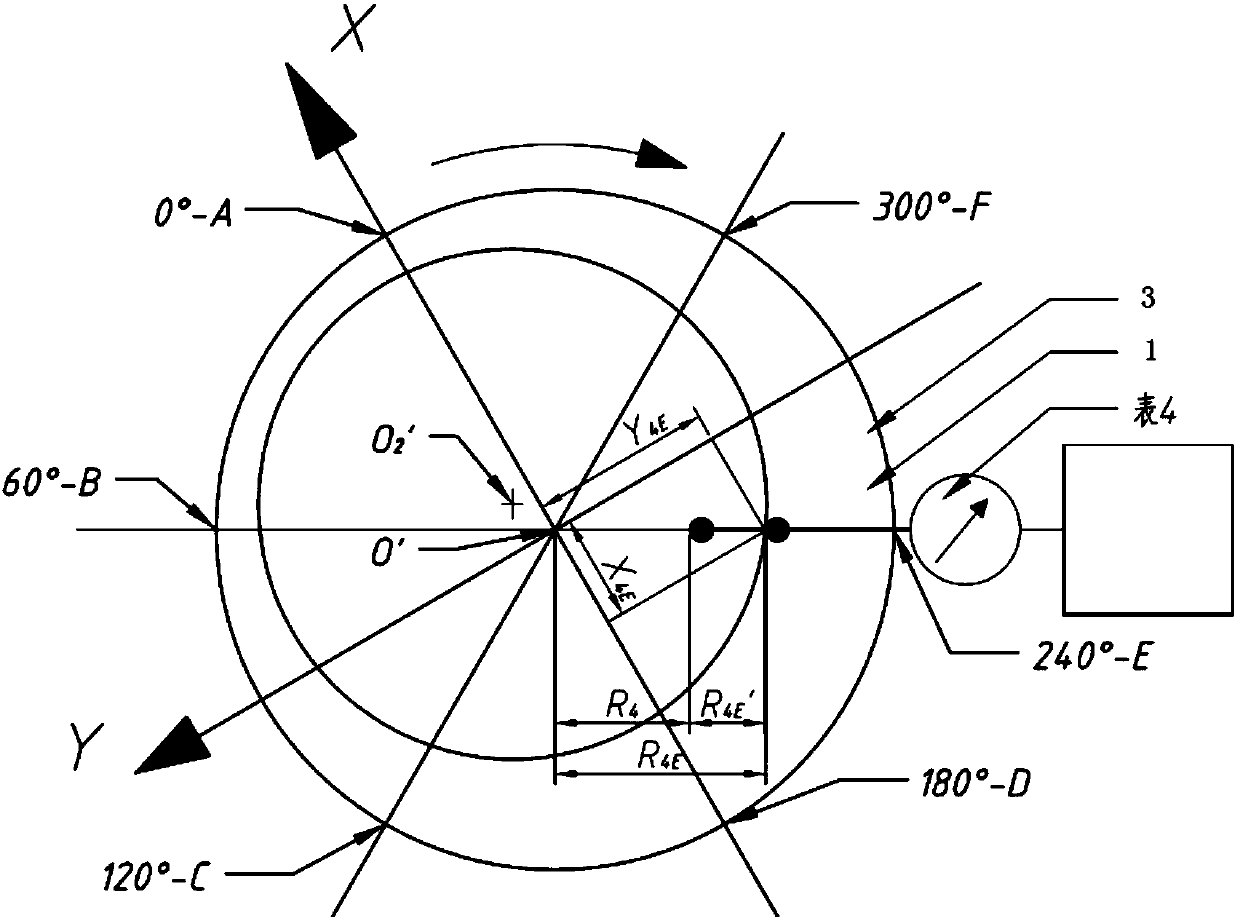

[0050] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0051] The invention provides a method suitable for detecting and adjusting the coaxiality of the aero-engine casing, which is different from the general rotation axis measurement method. The general rotation measurement first ensures that the reference axis of the casing coincides with the rotation center axis of the turntable through measurement and adjustment, and then By measuring the runout of the parts and performing data processing, it is judged whether the coaxiality of each part of the engine casing is qualified. However, this method is to first establish a coordinate system on the turntable, measure and obtain the coordinates of each measured point of the casing in this coordinate system, and then obtain the casing profile and pose information through the least squares fitting calculation, so as to achieve measurement and adjustment. The purpose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com