Method for determining content of saturates, wax and oil in rubber and rubber auxiliaries

A technology of rubber additives and determination methods, applied in the field of testing and analysis, can solve the problems of small amount of wax added, brittleness, mutual interference in analysis, etc., and achieve the effects of fast column passing speed, high accuracy and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

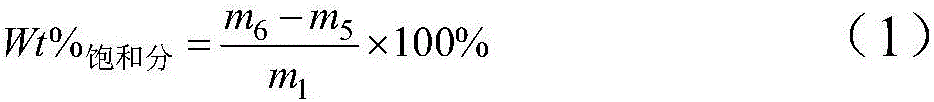

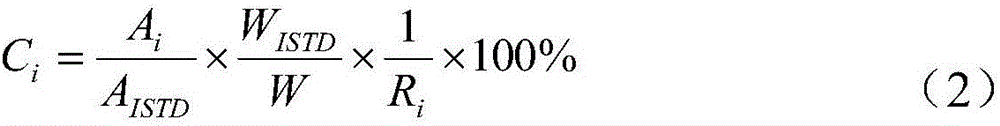

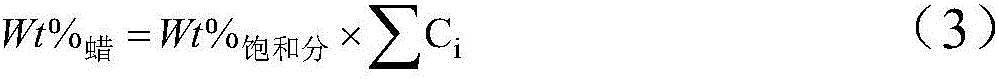

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1: the determination of wax and oil in known sample

[0065] 1.1 Preparation of known samples

[0066] Mix raw materials T110, 4020, RD, SP1068, OK1987, and P50 according to the following proportions, then heat and stir for 60 minutes to fully mix the raw materials and obtain samples with known wax and oil contents. The information of each raw material is shown in Table 1-1.

[0067] Table 1-1 Raw material information and ratio in known samples

[0068]

[0069] 1.2 Determination of saturated content in samples

[0070] 1.2.1 Column packing: Take a chromatographic column with an inner diameter of 1.0 cm and a height of 20 cm, weigh 2.0 g of silica gel (200-300 mesh) and put it in the chromatographic column; continue to weigh 1.5 g of clay adsorbent and put it in the chromatographic column On the upper layer of the column, a piece of glass wool is placed on top of the clay adsorbent. When filling, a rubber ball can be used to tap the outer wall of the col...

Embodiment 2

[0114] Embodiment 2: Change the column packing parameters and solvent B in the saturated content determination step, the sample loading and other test methods and steps remain unchanged, and continue the test, as follows:

[0115] 2.1 Determination of saturated content in samples

[0116] 2.1.1 Column packing: Take a chromatographic column with an inner diameter of 2.0cm and a height of 30cm, weigh 2.5g of silica gel (60-100 mesh) and put it in the chromatographic column; continue to weigh 2.0g of clay adsorbent and put it in the chromatographic column On the upper layer of the column, a piece of glass wool is placed on top of the clay adsorbent. When filling, a rubber ball can be used to gently tap the outer wall of the column to ensure that the adsorbent in the column has a similar density (the silica gel has been heated at 190°C for 4 hours to activate before loading the column).

[0117] 2.1.2 Weigh about 100mg of the sample into a 10ml volumetric flask, add 1ml of petrole...

Embodiment 3

[0129] Embodiment 3: the mensuration of saturated content in table tennis sponge film

[0130] 3.1 Sample extraction

[0131] 3.1.1 Crush the sponge film into a size of 1mm with a freeze grinder 3 For the left and right rubber powder particles, accurately weigh about 2g of rubber powder, wrap it with weighed filter paper, place it on a Soxhlet extraction device, and extract it with acetone for 8 hours.

[0132] 3.1.2 Remove the extracted sample from the Soxhlet extraction device, place the filter paper bag in an oven at 70°C for about 12 hours, and weigh the filter paper bag every 10 minutes. When the difference between the two weighings is 0.5 When it is within mg, it is considered that the solvent is completely removed, and the result of the second weighing is recorded.

[0133] 3.1.3 Transfer all the liquid in the extraction bottle to a pear-shaped bottle, wash the extraction bottle with clean acetone three times, transfer the solution into the pear-shaped bottle, and pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com