Device for detecting rigidity of gyration reduction gear

A technology of a rotary reducer and a detection device, which is applied to the measurement device, the test of mechanical parts, the test of machine/structural parts, etc., can solve the problems of low reliability of test results, low test efficiency, and inability to meet the needs of industrial production and use, etc. Achieve a high degree of automation, improve installation efficiency, and ensure the effect of installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

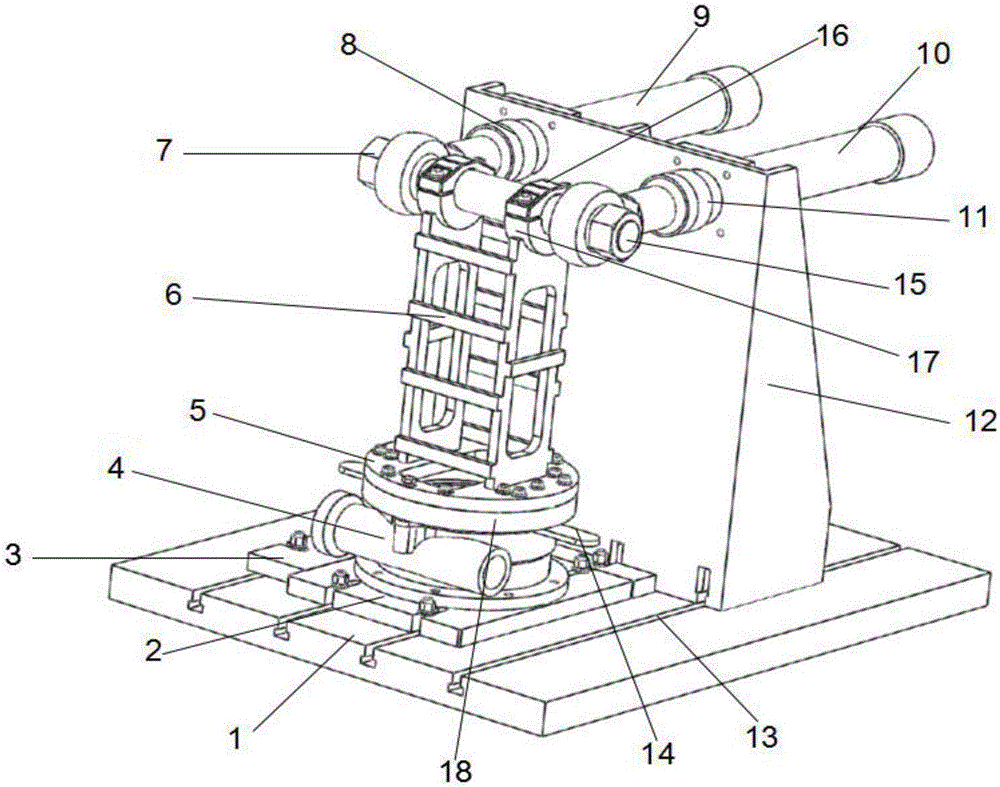

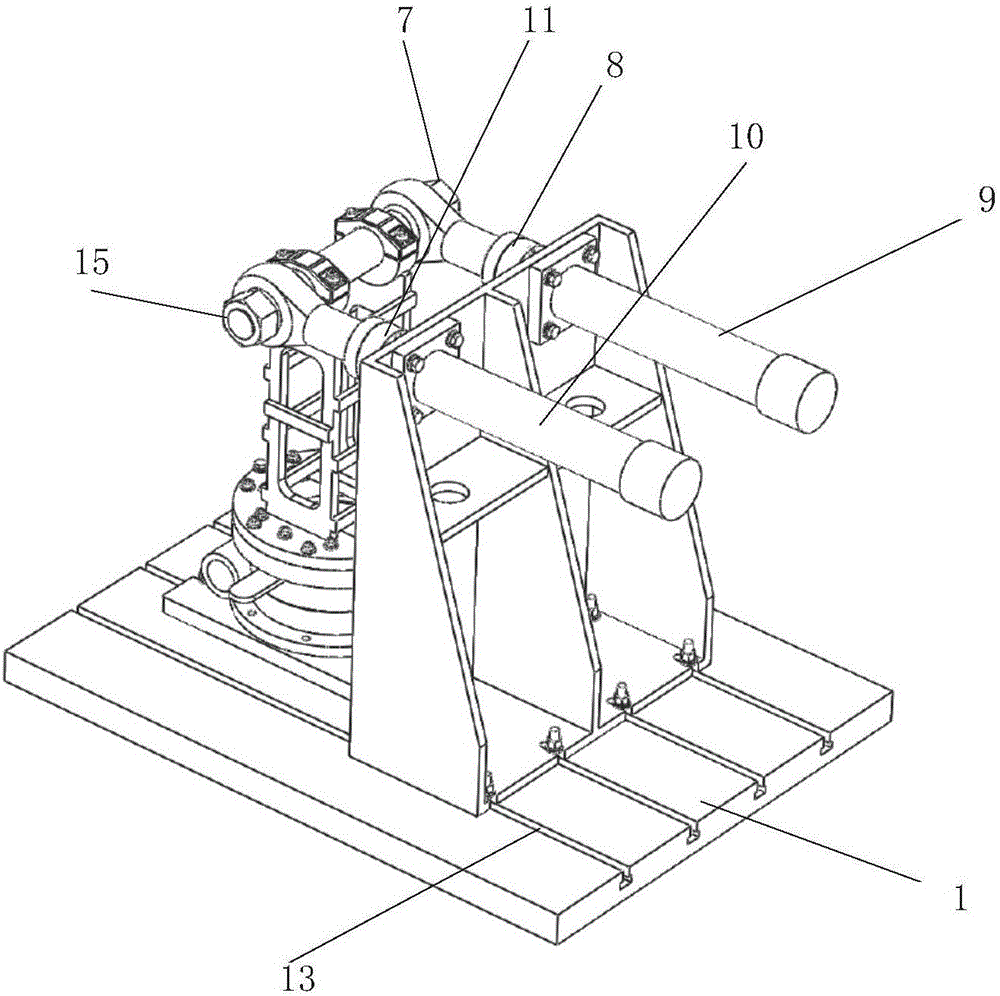

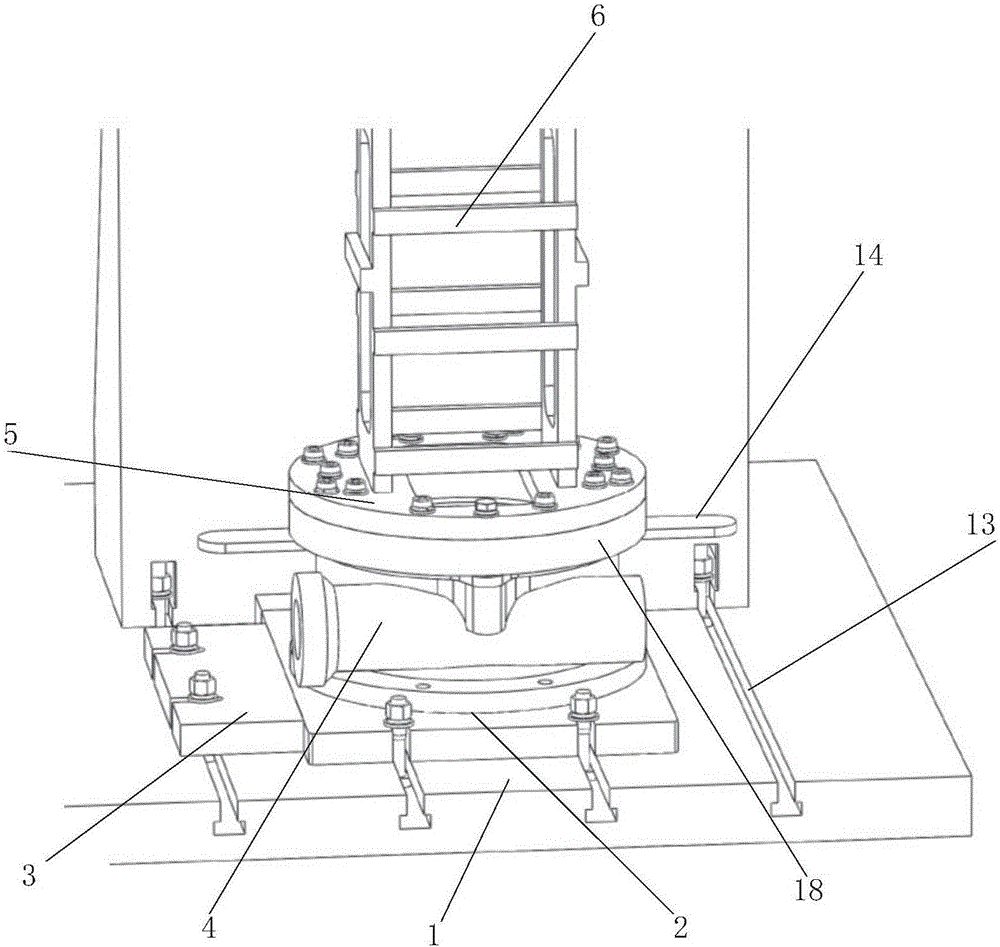

[0039] The rigidity detection device of the slewing reducer proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in very simplified form and use imprecise ratios, which are only used for the purpose of conveniently and clearly assisting in describing the embodiments of the present invention.

[0040] like Figure 4 As shown, the rotary reducer 4 includes a gear transmission structure, a rotary reducer housing 20 and a rotary reducer base 21, such as Figure 1 to Figure 4As shown, the rotary reducer rigidity detection device provided by the present invention includes: a base 1, a connecting seat, a first driving mechanism 9, a second driving mechanism 10, a displacement testing device (not shown in the figure) and a control center; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com