Equipment and method for measuring material damping factor

A material damping and factor technology, applied in measurement devices, analytical materials, instruments, etc., can solve the problems of high cost of measurement devices, complex testing devices, and high testing costs, and achieve the effects of simple measurement methods, shortened measurement time, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The structure of the device for measuring the material damping factor and the method for implementing the measurement designed in the present invention will be further described below according to the drawings and specific embodiments.

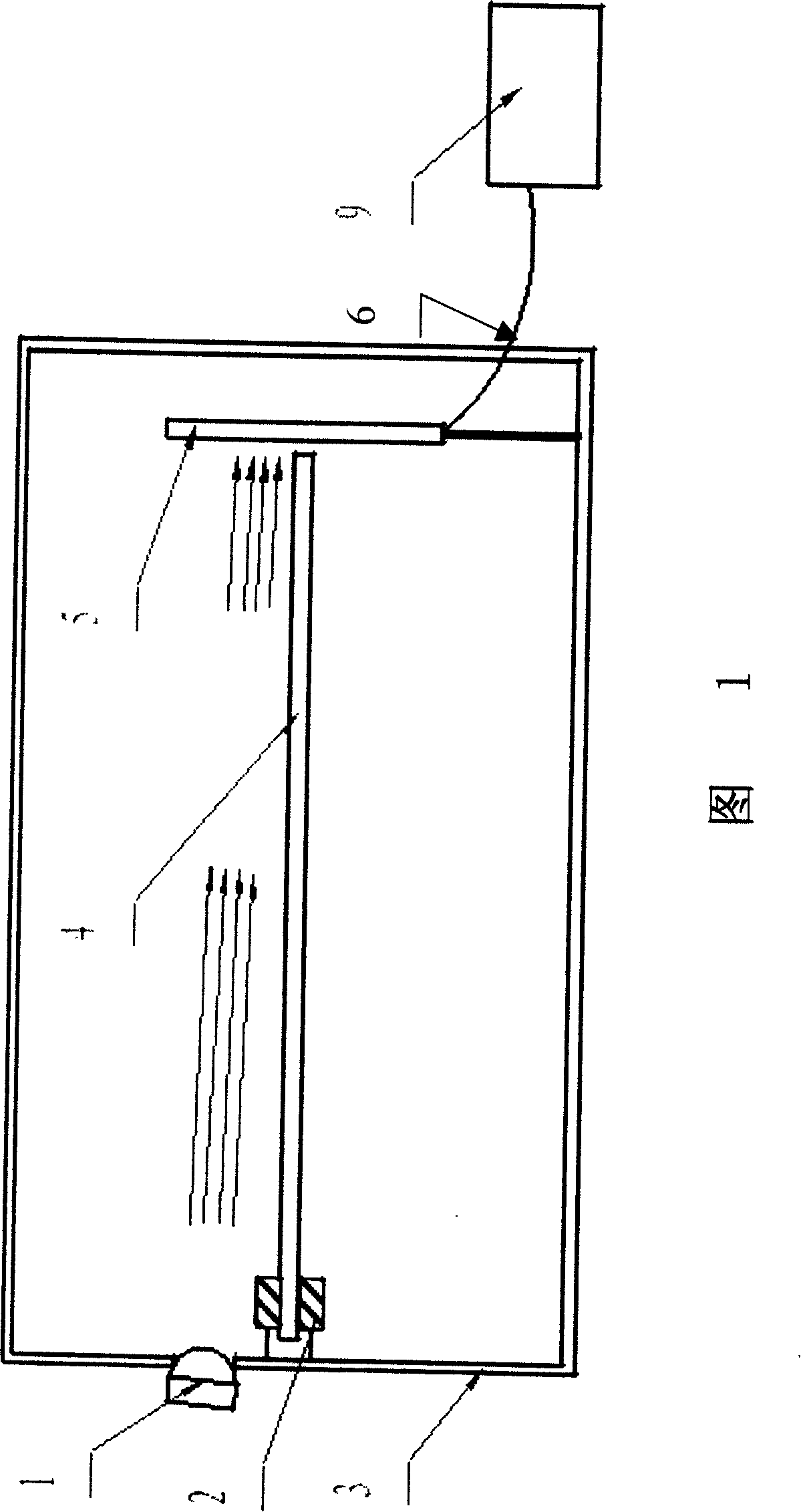

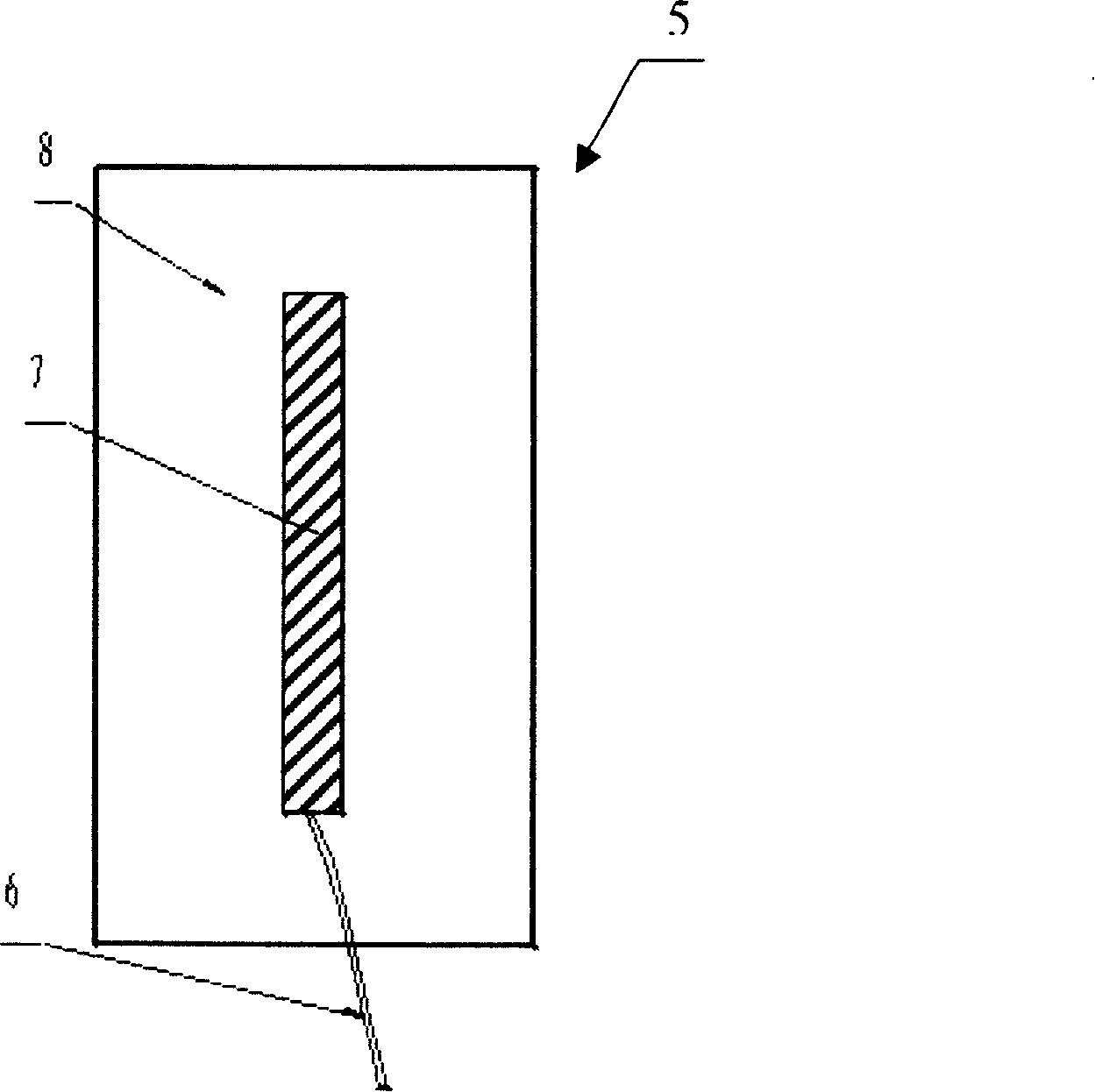

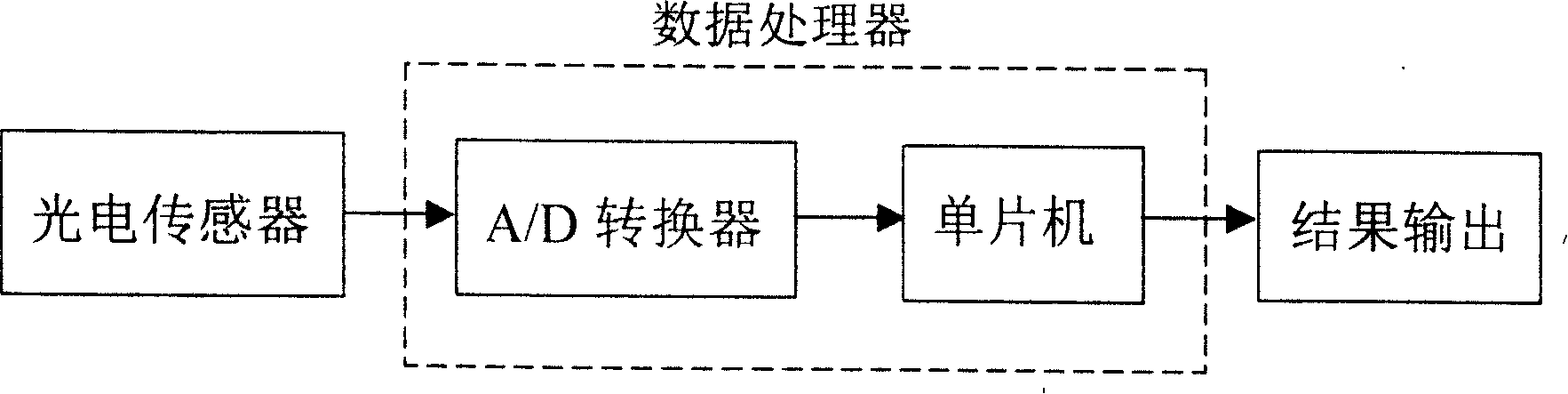

[0021] The equipment for measuring the damping factor of a material as shown in Figure 1 is composed of a measuring device and a data processing device 9. The measuring device is mainly composed of a light source 1, a fixture 2, a dark box 3, and a photocell sensor 5. The fixture 2 and the photocell sensor 5 are located in the dark box 3. Inside, the light source 1 is located on the side wall of the dark box 3, which is a constant white light source, illuminating in the direction of the photocell sensor 5 in the dark box 3. The photocell sensor 5 is installed on the side of the dark box opposite to the light source. figure 2 As shown, it is composed of a signal lead wire 6, a photovoltaic cell 7, and a back plate 8. The photovoltaic cell 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com