A conveying and metering device for powder auxiliaries used in the printing and dyeing industry

A metering device and powder technology, which is applied in the direction of measuring devices, conveying bulk materials, conveyors, etc., can solve the problems of low work efficiency, heavy labor, and low metering accuracy, and achieve the goal of improving metering accuracy and work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

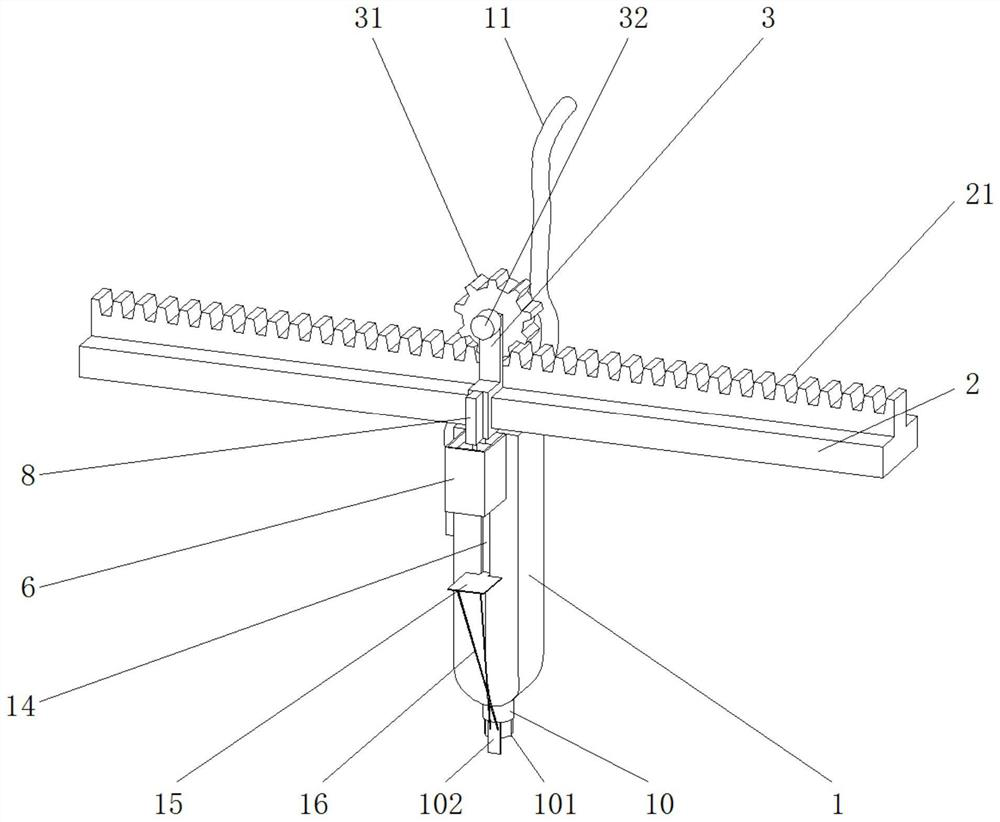

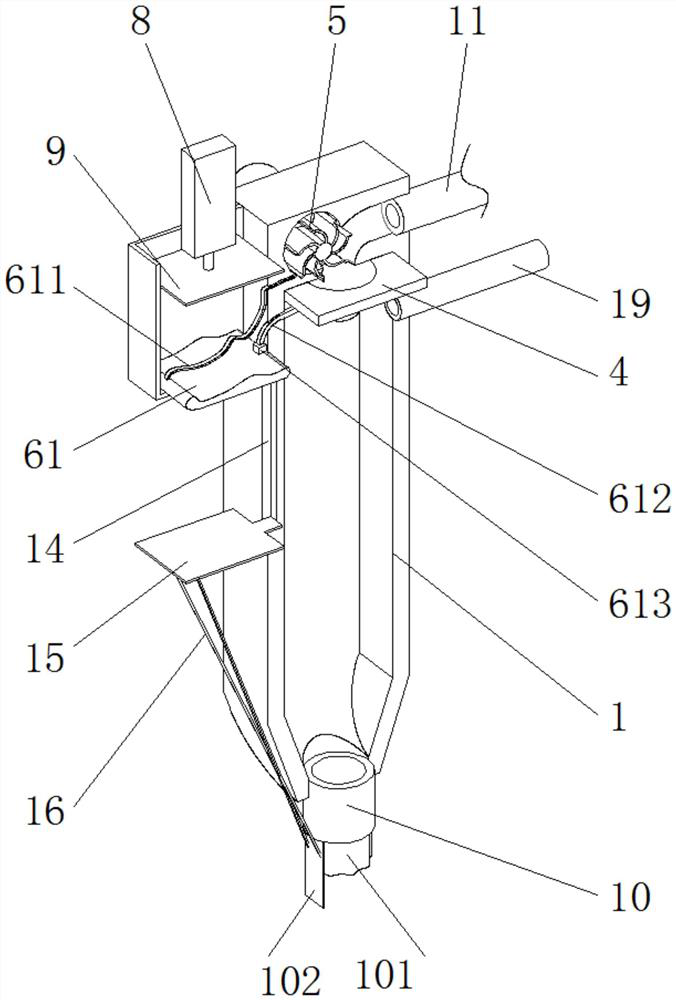

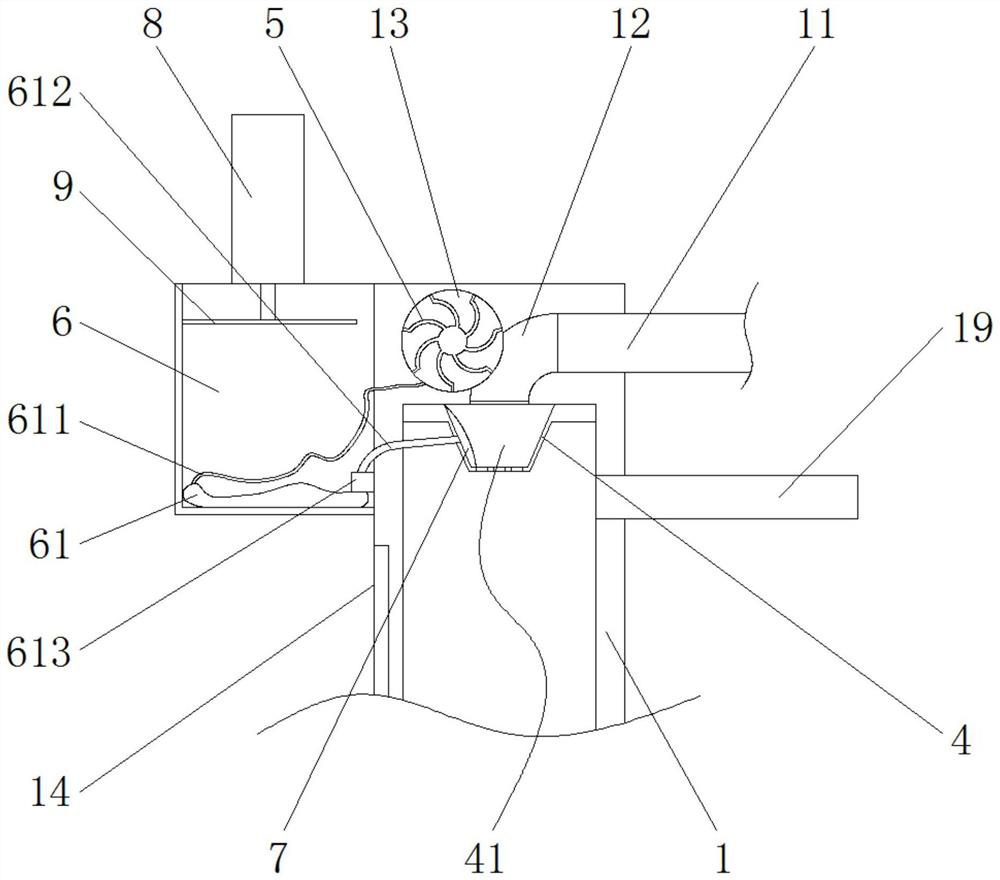

[0028] The embodiment of the present invention provides a conveying and metering device for powder auxiliaries used in the printing and dyeing industry, such as Figure 1-8 As shown, the powder additives are metered. It includes an injection chamber 1, the back of the injection chamber 1 is welded with an air pipe 11, an air guide groove 12 is opened inside the injection chamber 1, and the air pipe 11 is communicated with the air guide groove 12. An isolation plate 4 is welded in the injection chamber 1 , and the isolation plate 4 is located below the air guide groove 12 . A feed pipe 19 is welded on the back of the injection chamber 1 , and the feed end of the feed pipe 19 is located below the isolation plate 4 . A nozzle 10 is fixedly installed at the bottom of the injection chamber 1 , and a depression 41 is formed on the isolation plate 4 relative to the air guide groove 12 , and a plurality of leak holes 42 are formed in the depression 41 .

[0029] A cavity 13 is opene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com