Spatial pose detection and adjustment method for engine case assembly

A technology of engine casing and adjustment method, applied in the direction of using optical devices, measuring devices, instruments, etc., can solve the problems of difficult to achieve automatic assembly, difficult to automate, damage to workpieces, etc., to improve the detection accuracy and the degree of assembly automation , Reduce the operation of workers, the effect of accurate display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

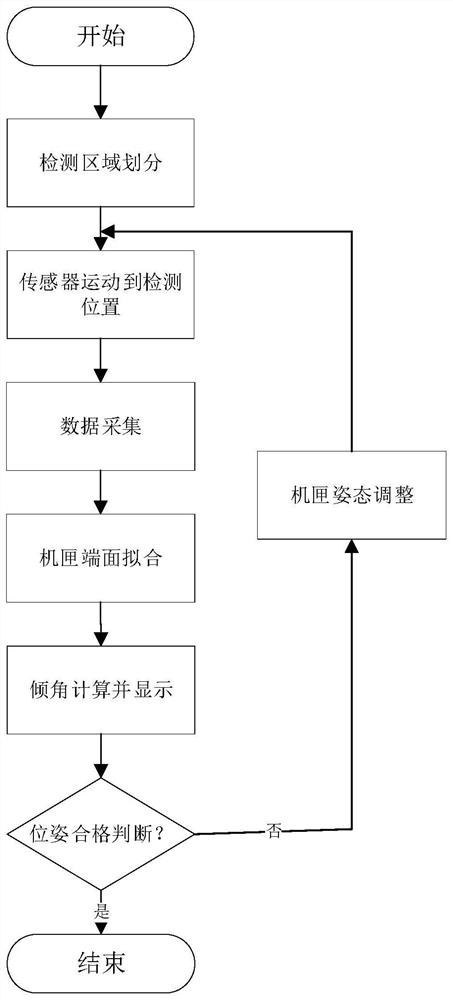

[0024] The present invention provides a method for detection and adjustment of the spatial position and attitude of the engine case assembly, combined with the actual production and assembly of an aero-engine, the specific process of realizing this solution is as follows figure 1 Shown:

[0025] Step 1. Data collection of sub-regions on the assembly surface

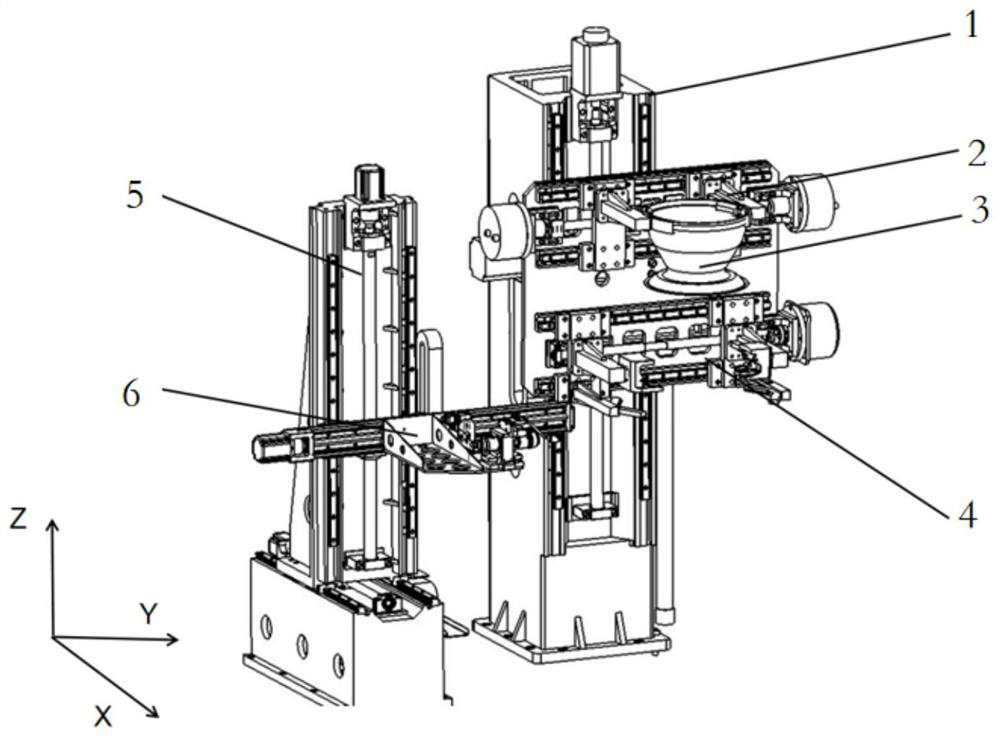

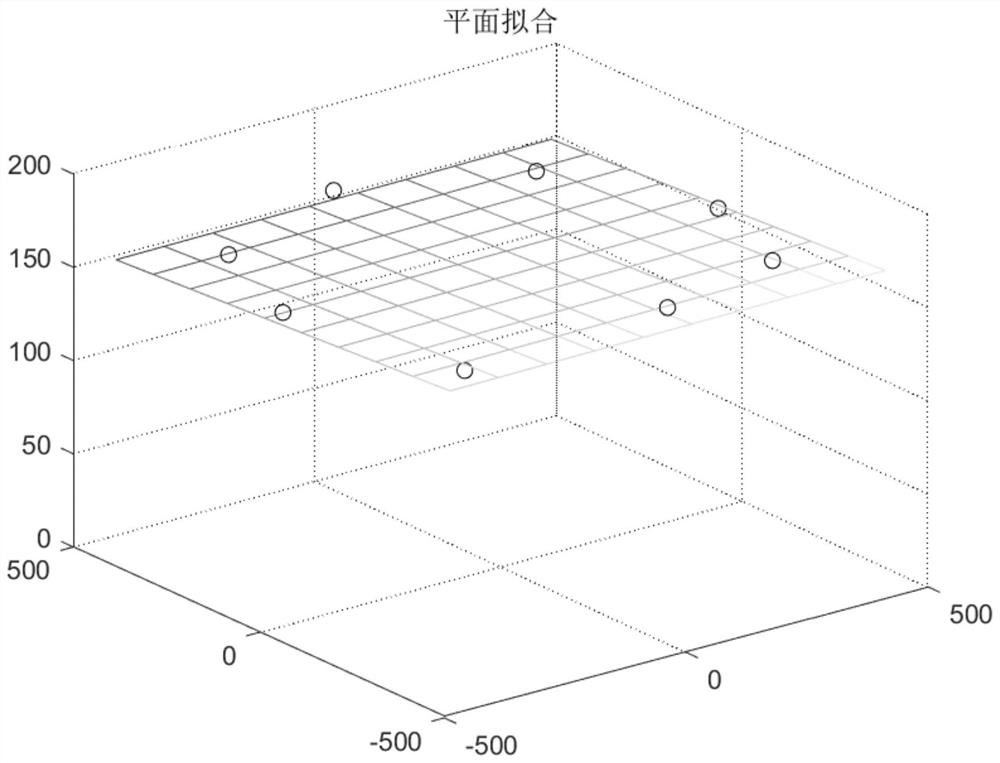

[0026] Fix the casing to be assembled on the assembly station, fix the laser sensor on the rotating turntable, and the optical path is vertically upward. Divide the casing assembly surface into 8 areas (according to the actual situation, the number of areas and the relative position relationship can be variable), move the laser sensor to the center point of the area, set n data collection positions, and record the laser display at this position respectively. number. During a data acquisition proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com