Automatic testing system for PCBs

An automatic test system and PCB board technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of difficulty in guaranteeing the quality of inspection, high labor intensity of inspectors, and easy fatigue of inspectors, so as to avoid repeated inspections. , shorten the detection time, reduce the effect of worker operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the content protected by the present invention is not limited to the following description.

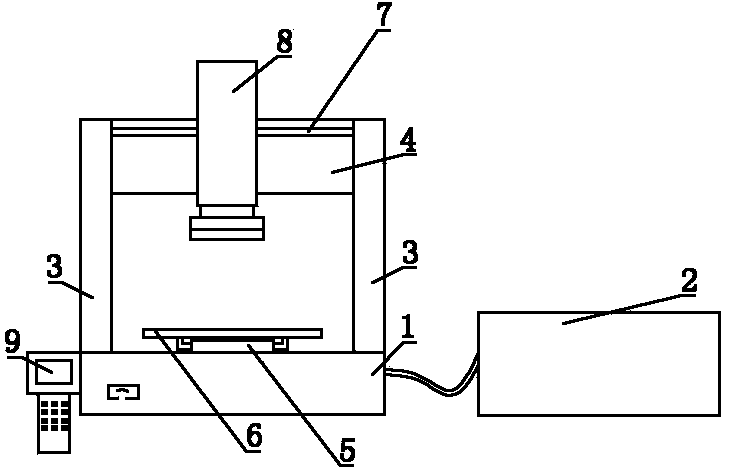

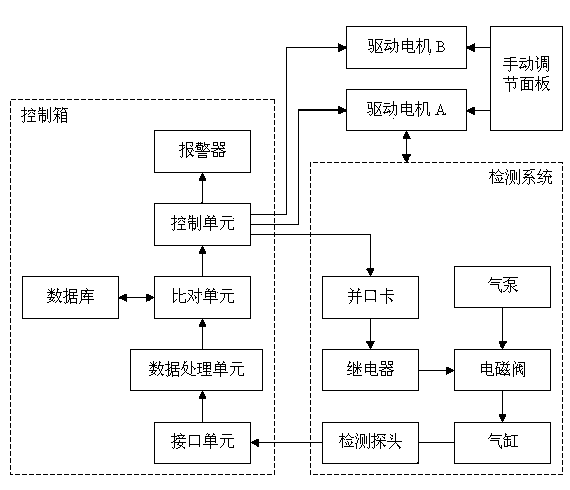

[0014] Such as figure 1 , figure 2 Shown, a kind of PCB board automatic testing system, it comprises base 1, support and control box 2, support is fixedly connected with the upper surface of base 1, described support comprises two vertical boards 3 and a crossbeam 4, the crossbeam 4 The two ends are respectively fixedly connected to one end of the two vertical plates 3, and the other ends of the two vertical plates 3 are respectively welded to the edge of the upper surface of the base 1, and the bracket is perpendicular to the upper surface of the base 1; the base 1 is provided with a Y-direction Guide rail 5, the fixed plate 6 used to fix the PCB board to be tested slides along the Y guide rail 5 driven by the drive motor A, the X guide rail 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com