Technology for plugging water bursting in mine by directional diversion grouting

A mine water inrush and grouting technology, applied in drainage, wellbore lining, mining equipment, etc., can solve the problems of water barrier effect damage, slurry waste, unsatisfactory sealing water inrush effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

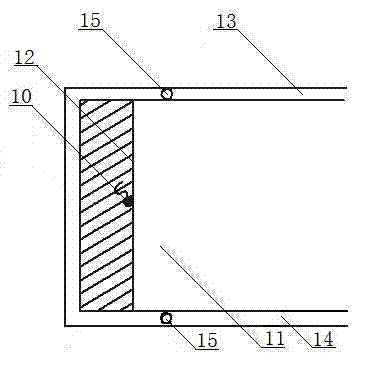

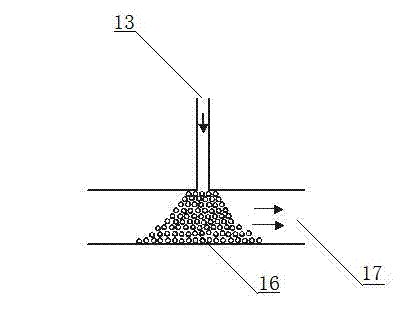

[0034] The directional diversion grouting plugging mine water inrush technology of the present invention performs directional diversion and drainage near the water inrush point, so that the still water condition becomes a micro-moving water condition, guides the fine aggregate and slurry to flow slowly through the water channel, and gradually Its plugging is to achieve the purpose of increasing the plugging water of grouting.

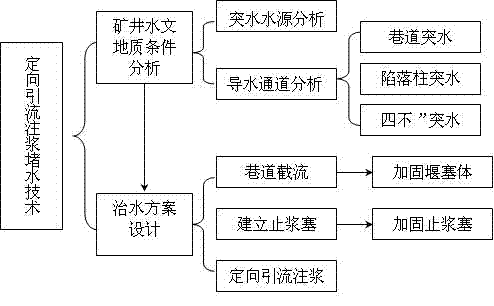

[0035] Refer to attached figure 1 The technology of directional diversion grouting to block mine water inrush specifically includes the following steps:

[0036] 1. Analysis of mine hydrogeological conditions

[0037] Because the directional diversion grouting water plugging technology has its specific application conditions, it is necessary to analyze the hydrogeological conditions of the mine before deciding to use the grouting technology. It mainly includes the causes of water damage, the amount of water inrush, the source of water inrush, the natu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com