Supercritical machine set steam temperature control method and system based on multivariable predictive control

An ultra-supercritical unit, predictive control technology, applied in the direction of temperature control using electric methods, can solve problems such as lag adjustment, achieve the effect of overcoming interference and maintaining stability, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

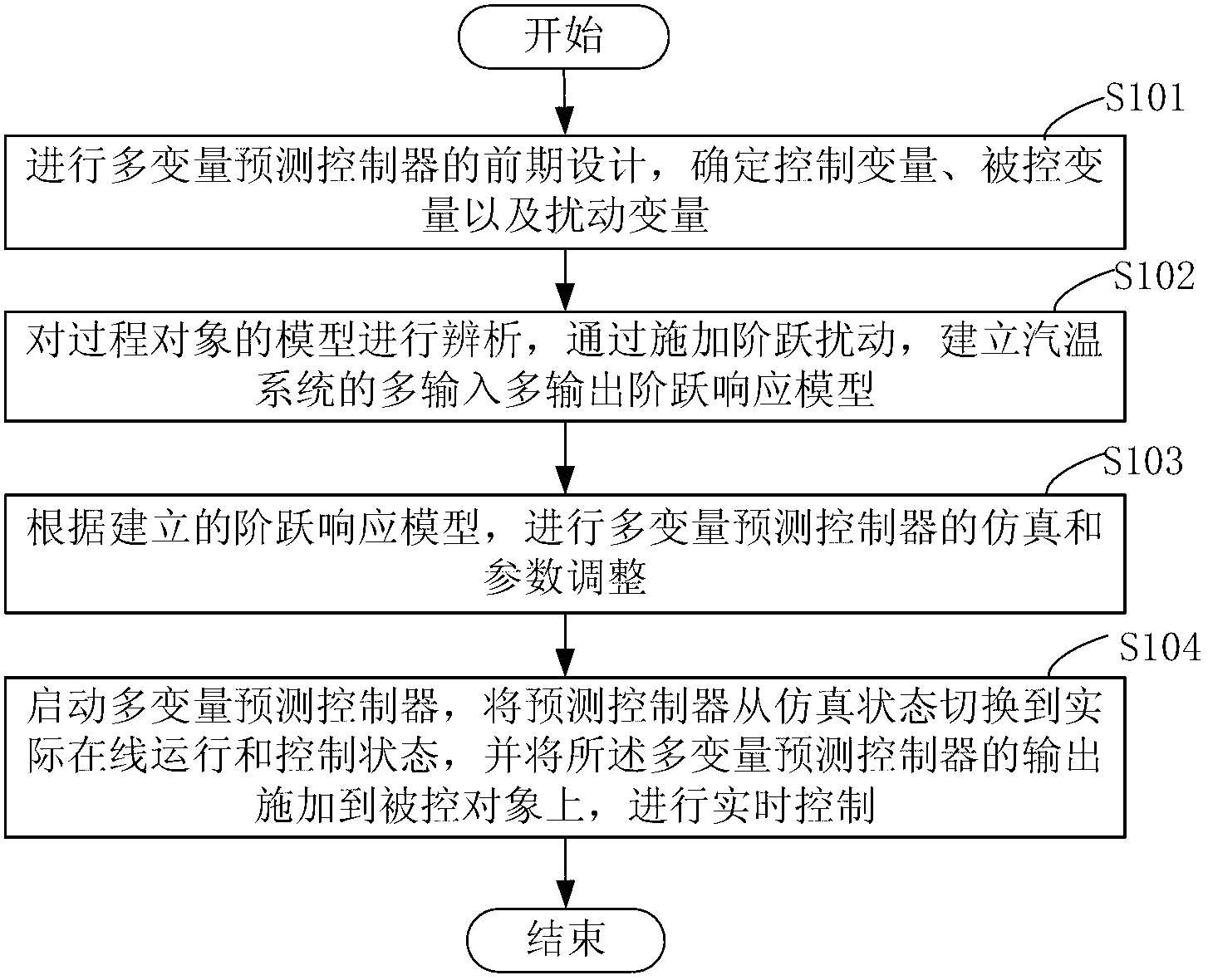

[0020] Such as figure 1 As shown, a method for controlling the steam temperature of an ultra-supercritical unit based on multivariable predictive control is characterized in that it includes the following steps:

[0021] In step S101, the preliminary design of the multivariable predictive controller is carried out, mainly to determine the control variable, the controlled variable and the disturbance variable.

[0022] When applying multivariable predictive controllers, it is necessary to be very familiar with process objects. Therefore, in this step, the designer needs to be familiar with the relevant knowledge of the process object, communicate with the operator and technical personnel, and complete the pre-design of the controller. Because the selection of variables is very closely related to the entire process, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com