Reactive purge compound for polymer purging

一种聚合物、化合物的技术,应用在清洗化合物领域,能够解决非均匀色、聚合物脱色等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

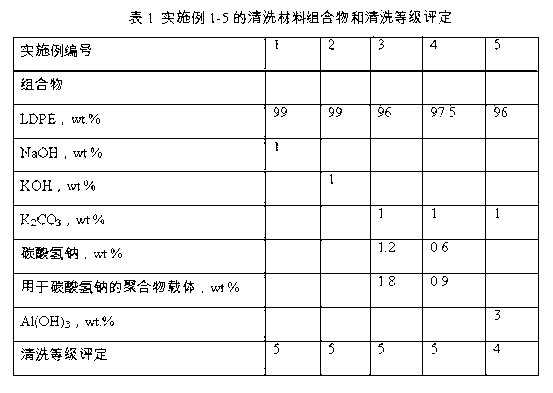

Embodiment 1

[0083] First, an aqueous solution of sodium hydroxide was sprayed onto pellets of low-density polyethylene (Petrothene® NA960000 purchased from Equistar Chemicals, and measured at 190° C. / 2.16 kg according to ASTM D1238-04 to have a melt of about 0.8 g / 10 min flow rate) to prepare the cleaning compound such that the ratio of low density polyethylene to sodium hydroxide is about 99:1 when drying the coated pellets. The low density polyethylene (LDPE) was dried at about 100°C for about 16 hours to remove water before extrusion. The coated pellets containing LDPE and sodium hydroxide were melt compounded on a Killion single screw extruder with a screw diameter of about 31.75 mm and a length / diameter ratio (L / D) of about 24:1. The extruder was equipped with a barrel extension (304.8 mm long) to accommodate the screw chopper section (such as the one disclosed in US Patent 6,062,717, incorporated herein by reference) and to enhance mixing and dispersion . Including barrel extensio...

Embodiment 2

[0093] Example 2 was prepared and evaluated using the same materials and methods as described in Example 1, except that about 1 wt.% KOH was used instead of 1 wt.% NaOH as the chain scission catalyst.

Embodiment 3

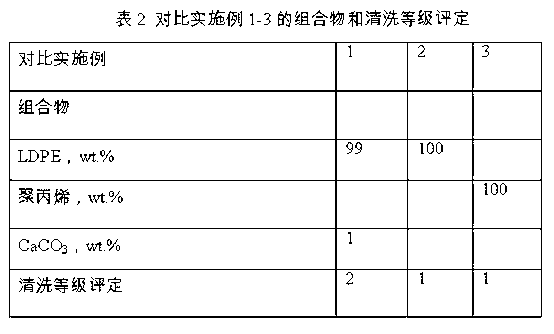

[0095] Except 1wt.% anhydrous potassium carbonate (K 2 CO 3 ), Example 3 included the first portion of the cleaning compound prepared and evaluated using the same materials and methods as described in Example 1. Example 3 was then prepared by dry blending the first part of the purge compound with Polyfil SBC-4000 (sodium bicarbonate concentrate in a thermoplastic containing polyolefin carrier resin) at a rate of about 97 wt.% to about 3 wt.%. The concentration of sodium bicarbonate in Example 3 was about 1.2 wt.%, based on the total weight of the cleaning compound.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt Flow Rate | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| Melt Flow Rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com