Full-automatic DLP (Digital Light Processing) light machine position adjusting method and device

An adjustment method and a fully automatic technology, applied in the field of optical projection systems, can solve problems such as inconsistency and subjectivity of picture observation, and achieve the effects of improving accuracy, saving manpower and material resources, and eliminating subjectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

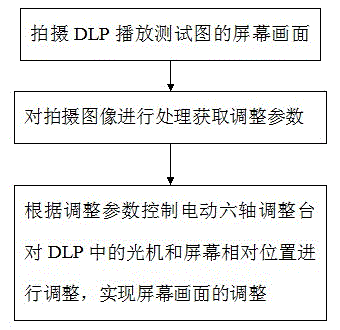

[0065] Such as figure 2 As shown, it is a flowchart of a fully automatic DLP optical machine position adjustment method in the present invention, and the specific steps of a fully automatic DLP optical machine position adjustment method include:

[0066] (S101) Shooting a screen image of a DLP playback test pattern;

[0067] (S102) Process the captured image to obtain adjustment parameters;

[0068] (S103) Control the electric six-axis adjustment table according to the adjustment parameters to adjust the relative position of the optical machine in the DLP and the screen, so as to realize the adjustment of the screen image.

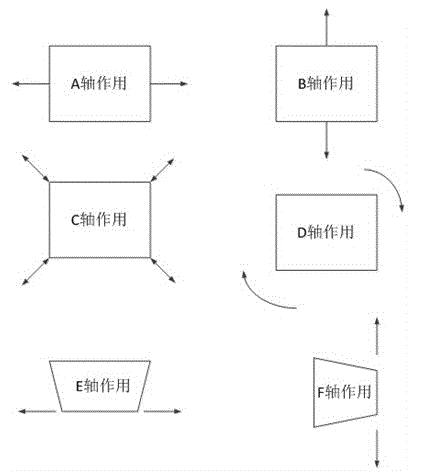

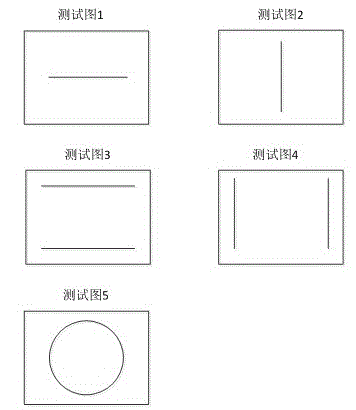

[0069] In practical applications, one axis of the electric six-axis adjustment table corresponds to one test chart. For step (S101), DLP plays different test charts for different axes, so that the captu...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap