Circulating dust generating device

A technology of dust and circulation pipes, which is applied in the direction of measuring devices, suspension and porous material analysis, instruments, etc., can solve inconvenience and other problems, and achieve the effect of flexible dust measurement, convenient picking and placing, and stable dust environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

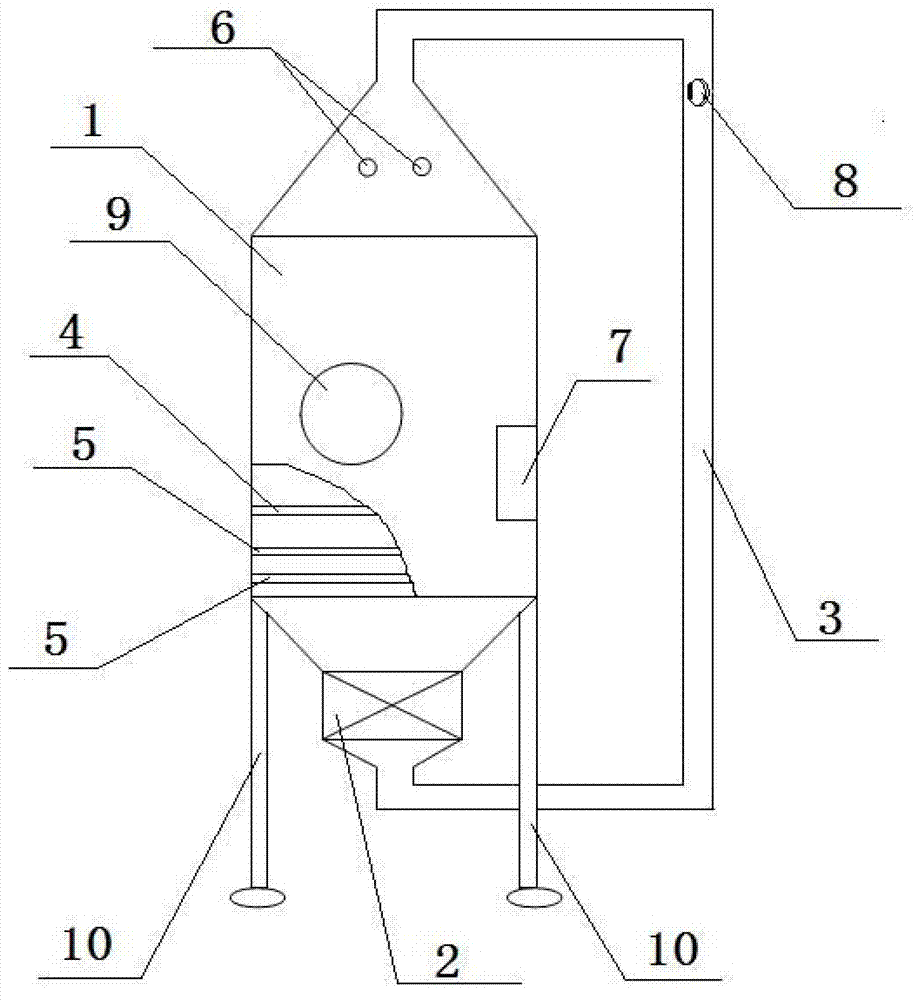

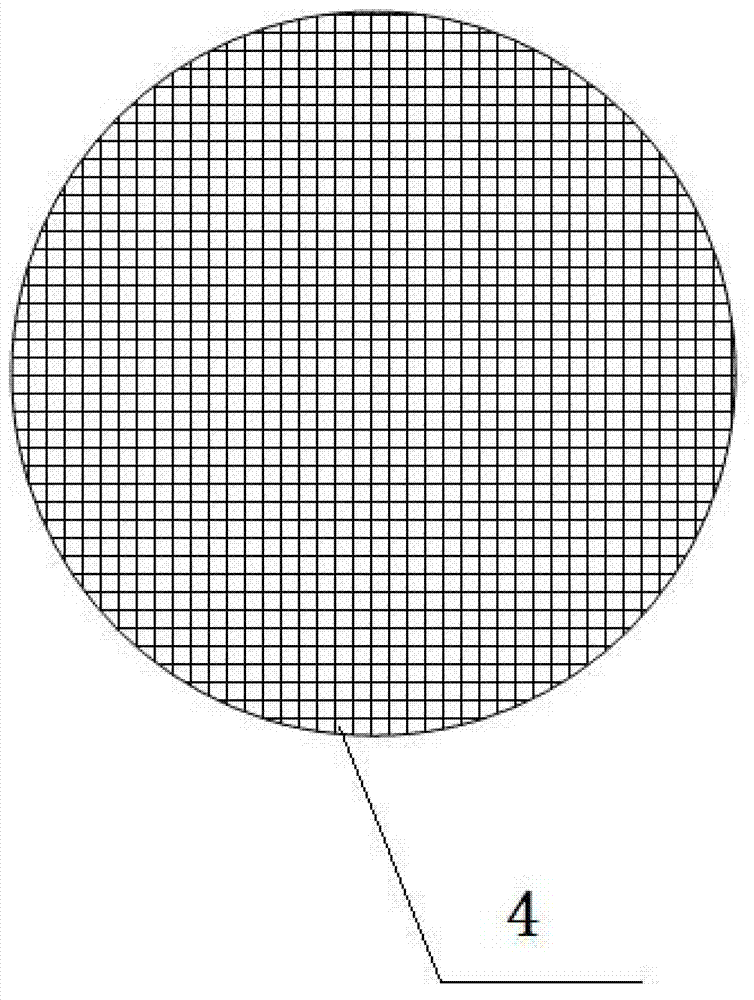

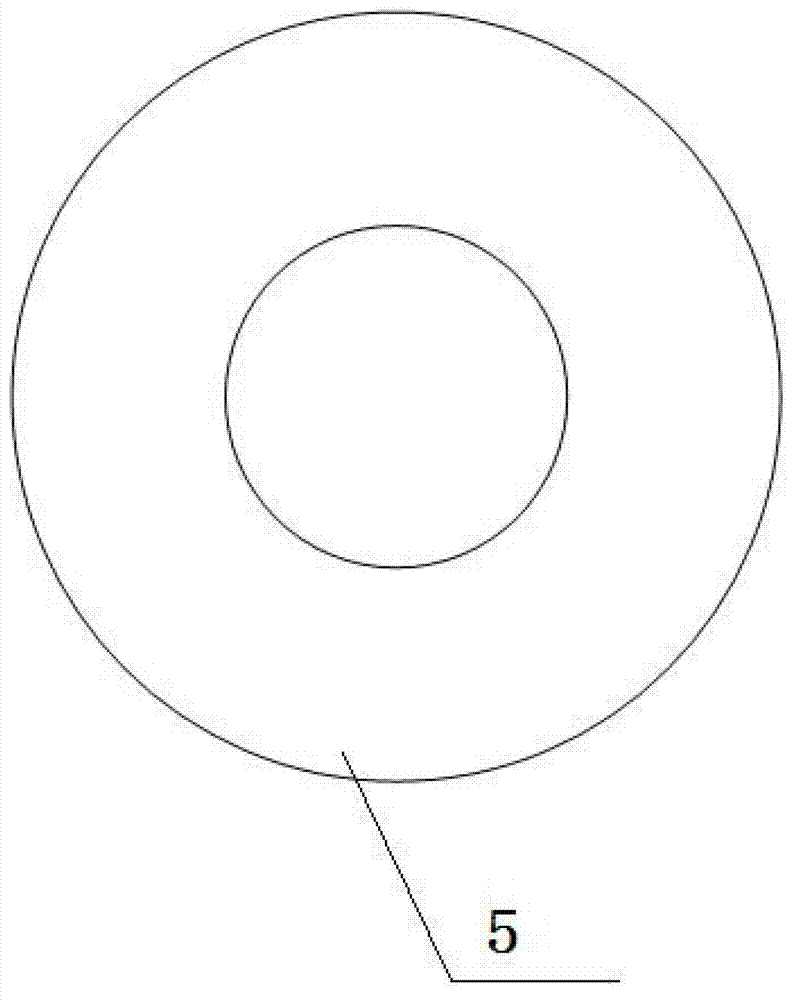

[0018] Embodiment one: if Figure 1 to Figure 3 As shown, a circulating dust generating device includes a cavity 1, an axial flow fan 2, a circulation pipe 3, a mesh-like support 4, an annular rectifying plate 5, a sealing door 7 and a cavity support 10; the cavity 1 Both the top and the bottom have openings, the top of the cavity 1 protrudes upwards to form a conical top; the bottom of the cavity 1 protrudes downwards to form a conical bottom, and one end of the axial flow fan 2 is fixed in the cavity The opening at the bottom of the body 1, the other end of the axial flow fan 2 is connected to the opening at the top of the cavity 1 through a circulation pipe 3, the cavity 1 is provided with a sealing door 7, and the cavity 1 is horizontal A mesh-shaped support 4 is welded, and two annular rectifying plates 5 are also welded in the cavity 1, and the two annular rectifying plates 5 are welded on the conical bottom of the mesh-shaped support 4 and the cavity 1 In between, the ...

Embodiment 2

[0022] Embodiment two: if Figure 4 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is: the mesh-shaped support 4 abuts against the conical bottom of the cavity 1, and the mesh-shaped support 4 and the axial flow fan 2 Two annular rectifying plates 5 are arranged between them, and the two annular rectifying plates 5 are welded on the conical bottom of the cavity 1. Since the mesh-shaped support 4 is not fixed to the inside of the cavity 1, it can pass through the airtight door 7 Remove for cleaning or replacement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com