Jack without vibratory noise

A jack and noise technology, applied in the field of environment-friendly hydraulic jacks, can solve the problems of vibration, noise, disturbing people, etc., and achieve the effect of eliminating the noise caused

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will further describe the present invention in conjunction with the accompanying drawings of the embodiment, which will help the public to understand the technical content and effect of the case, but the description of the embodiment does not constitute a limitation to the technical solution. Any transformation that is merely equivalent in form should be regarded as the scope of the technical solution of this case.

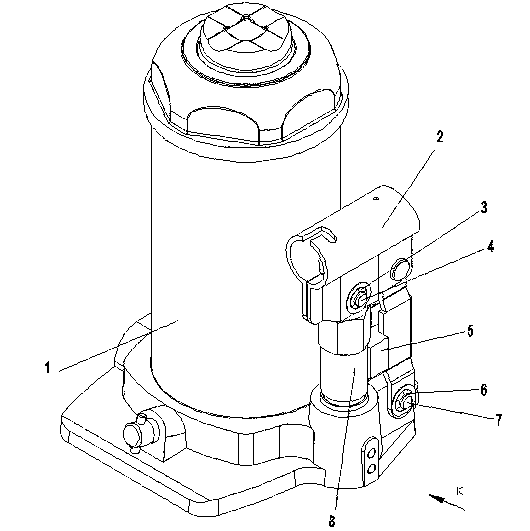

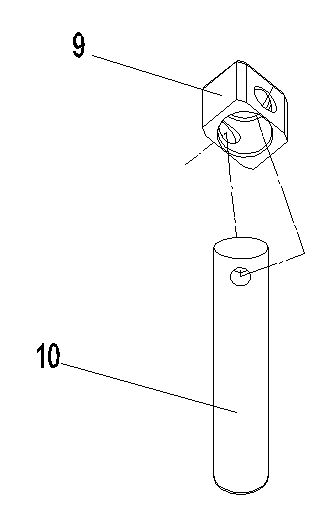

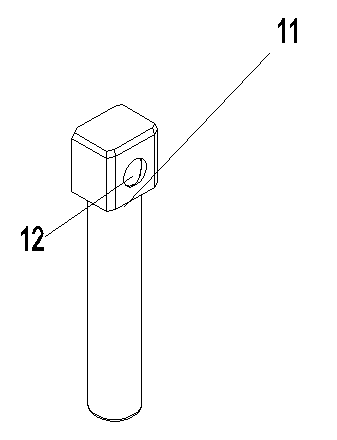

[0024] It can be seen from the accompanying drawings that the embodiment of the present invention is based on the traditional hydraulic jack, relying on the oil cylinder assembly 1, the pump cylinder 8, the middle hole 19 of the pump cylinder, the push lever assembly 2, the pump core 10, and the first pin shaft 4 , the second pin shaft 7, the second retaining ring groove 18, the first retaining ring groove 25 and other structural parts and elements, the pump core assembly 11 is formed by the combination of the flexible shock-isolating cap 9 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com