Method for preparation of polyolefin microporous membrane by wet process

A technology of polyolefin microporous film and polyolefin resin, which is applied in the direction of flat products, applications, electrical components, etc., to achieve the effects of maintaining excellent performance, uniform product thickness, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

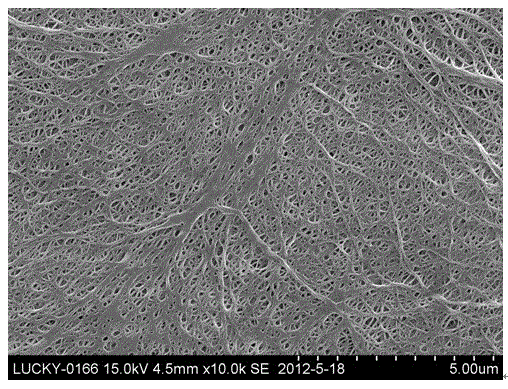

Image

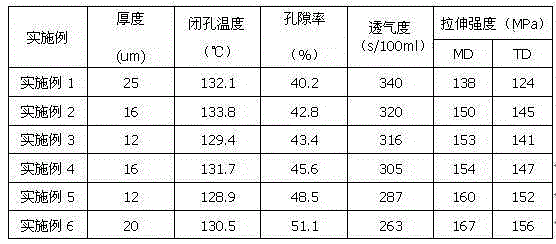

Examples

Embodiment 1

[0041] (1) First, dissolve the antioxidant in liquid paraffin, and then inject the polyolefin resin into the twin-screw extruder through different feeding ports. Among them, the mass ratio of antioxidant to polyolefin resin is 1:5000, and the mass ratio of polyolefin resin to liquid paraffin is 1:2;

[0042] The antioxidant in this example uses hindered phenolic antioxidant β-(3,5-di-tert-butyl-4-hydroxyphenyl) n-octadecyl propionate, code 1076, and the polyolefin resin is viscous Polyethylene resin with an average molecular weight of 500,000 and a viscosity grade of liquid paraffin of 45.

[0043] (2) In the extruder, under the action of twin-screw mixing, dispersion and shearing, the above raw materials are melted and mixed into a uniform melt. Wherein, the gradient control temperature range is between 60°C and 210°C.

[0044] (3) The melt is continuously extruded from the die, and rapidly cooled and formed by cooling rollers to obtain thick sheets. Wherein, the temperatu...

Embodiment 2

[0050] (1) First, dissolve the antioxidant in liquid paraffin, and then inject the polyolefin resin into the twin-screw extruder through different feeding ports. Among them, the mass ratio of antioxidant to polyolefin resin is 1:2000, and the mass ratio of polyolefin resin to liquid paraffin is 1:4.5;

[0051] The antioxidant used in the present embodiment is phosphite antioxidant dioctadecyl pentaerythritol diphosphite, code name 618 or PEP-8T; Polyolefin resin is polyethylene resin with molecular weight 1,000,000, liquid paraffin The viscosity grade is 70.

[0052] (2) In the extruder, under the action of twin-screw mixing, dispersion and shearing, the above raw materials are melted and mixed into a uniform melt. Wherein, the gradient control temperature range is between 60°C and 210°C.

[0053] (3) The melt is continuously extruded from the die, and rapidly cooled and formed by cooling rollers to obtain thick sheets. Wherein, the temperature of the cooling roll is contro...

Embodiment 3

[0058] (1) First, dissolve the antioxidant in liquid paraffin, and then inject the polyolefin resin into the twin-screw extruder through different feeding ports. Among them, the mass ratio of antioxidant to polyolefin resin is 1:1000, and the mass ratio of polyolefin resin to liquid paraffin is 1:6;

[0059] The antioxidant used in this example is didodecyl thiodipropionate, code-named PS800 or DLTDP; the polyolefin resin is a polyethylene resin with a molecular weight of 200,000 and 2 million mixed in a ratio of 1:9, and the liquid Paraffin wax has a viscosity grade of 75.

[0060] (2) In the extruder, under the action of twin-screw mixing, dispersion and shearing, the above raw materials are melted and mixed into a uniform melt. Among them, the gradient control temperature range is between 70-220°C.

[0061] (3) The melt is continuously extruded from the die, and rapidly cooled and formed by cooling rollers to obtain thick sheets. Wherein, the temperature of the cooling r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com