Automatic feeding device and jewelry wire cut-off machine comprising same

An automatic feeding and feeding technology, applied in the field of feeding devices, can solve the problems of rising production cost of jewelry products, low production efficiency, and complicated controllability, so as to improve the feeding processing efficiency, improve production efficiency, and improve The effect of precise procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

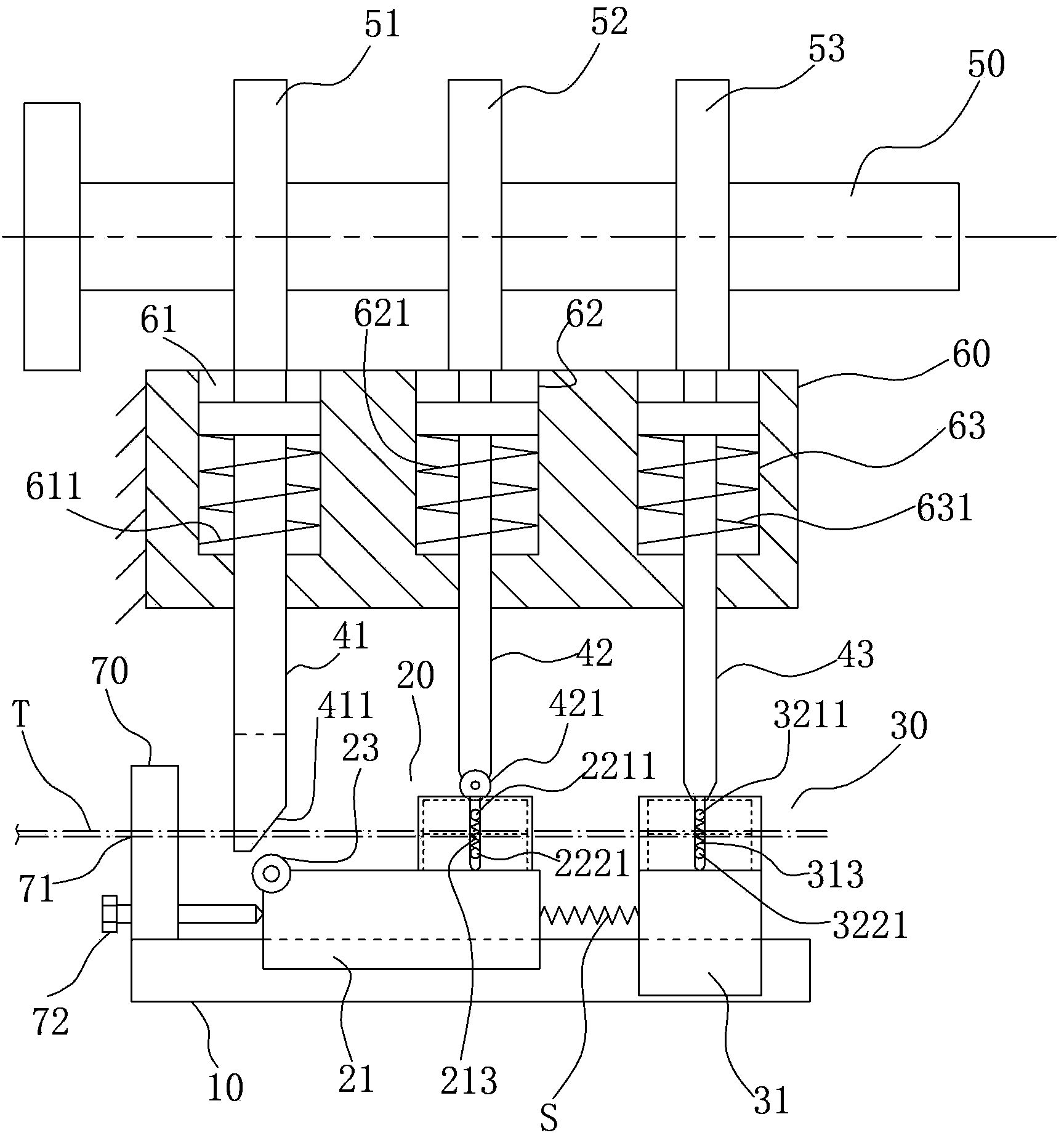

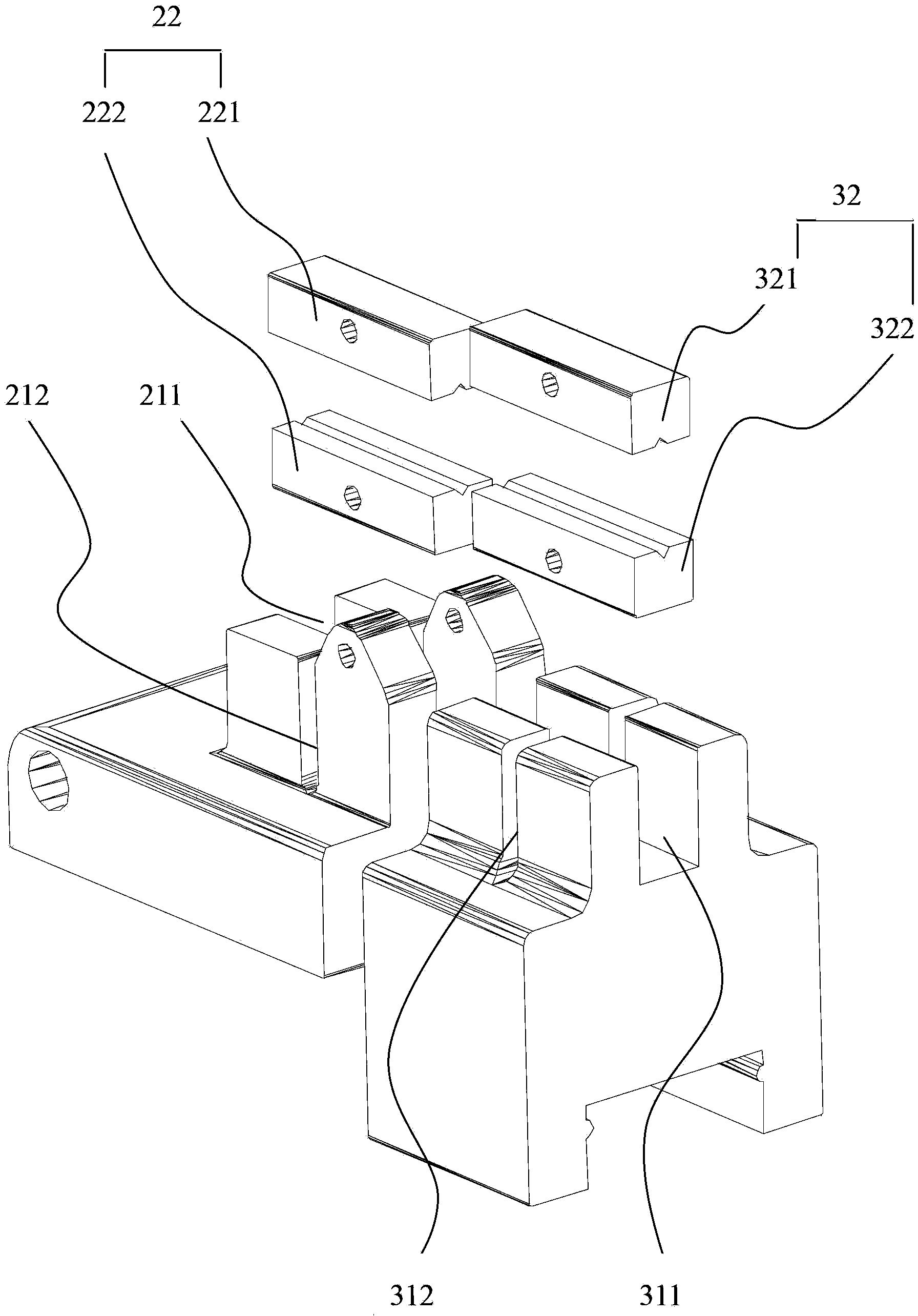

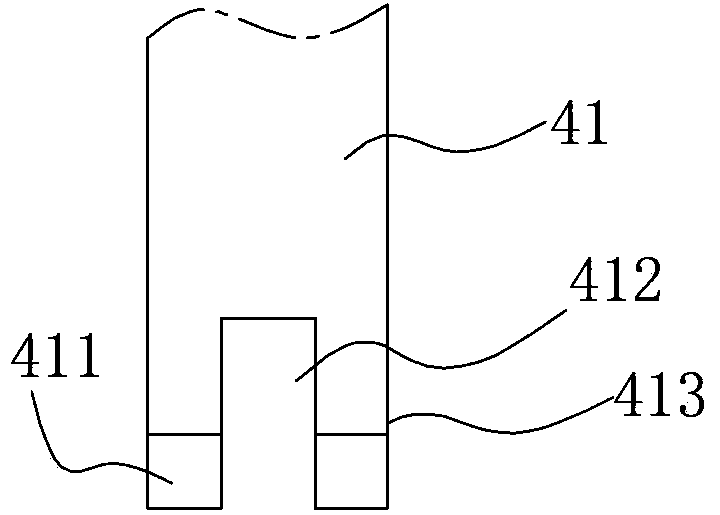

[0053] Such as Figure 1 to Figure 3As shown, the specific embodiment of the jewelry processing wire used in the automatic feeding device of the present invention includes a base 10, a slider assembly 20 slidingly coupled with the base 10, a pressing block assembly 30 fixedly coupled with the base 10; The assembly 20 includes a slider body 21, a lock block 22 arranged on the slider body 21, a feed roller 23 arranged at the feeding end of the slider body 21; a first ejector rod 41 arranged above the slider assembly, a second Two ejector rods 42, the lower end of the first ejector rod 41 is provided with an inclined plane 411 in pressure contact with the feed roller 23, and the lower end of the second ejector rod 42 is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com