Novel core-pulling mechanism with inner circle full circumference reverse buckle

A technology of core-pulling mechanism and undercut, which is applied in the field of novel inner-circle full-periphery undercut core-pulling mechanism, can solve the problems of wasting manpower, difficult quality control, and production efficiency, so as to save resources and improve production efficiency , Improve the effect of core pulling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

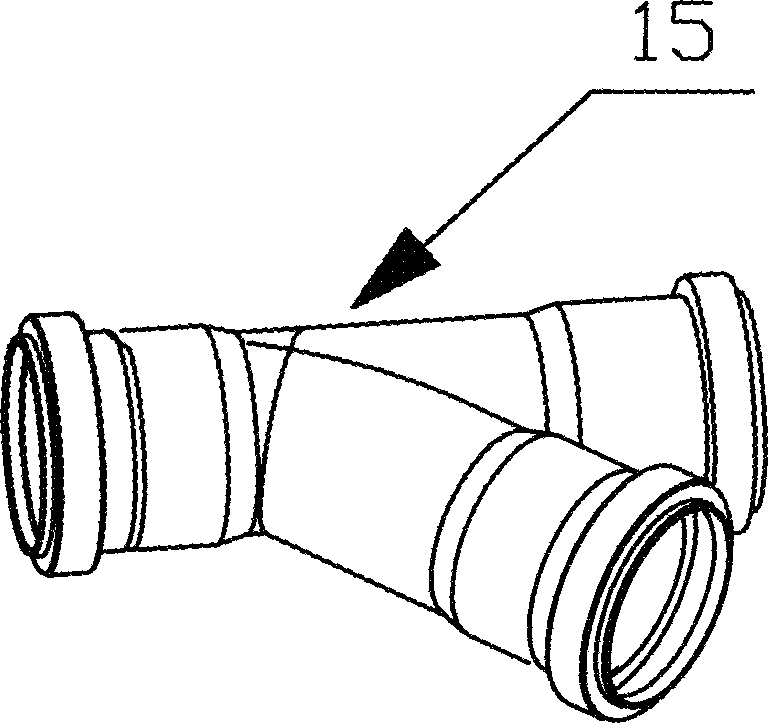

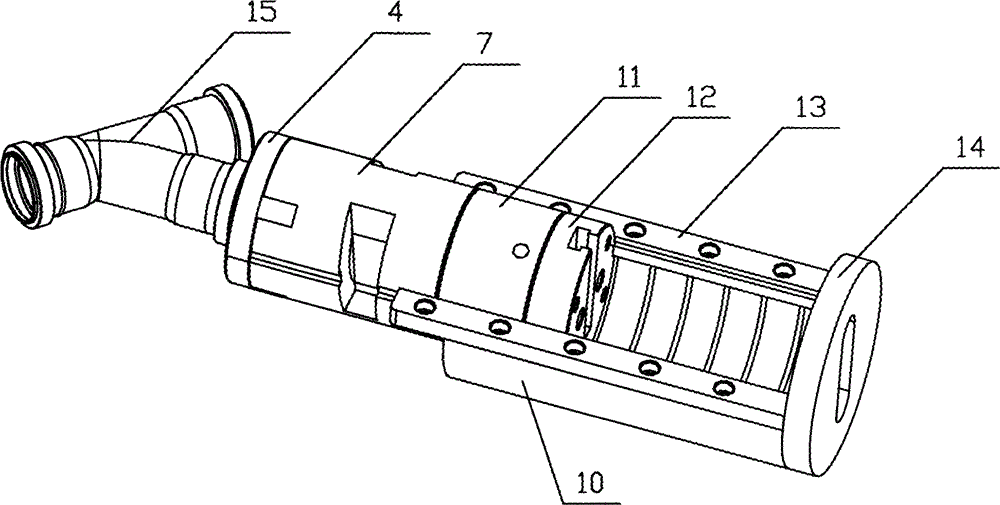

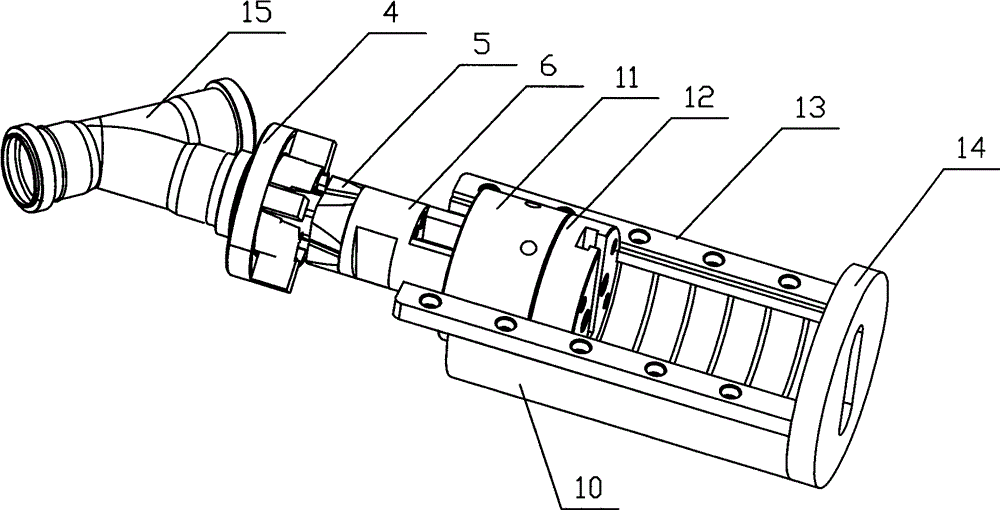

[0019] refer to Figure 1-Figure 10 As shown, the present invention is a kind of novel inner circle full circumference undercut core-pulling mechanism, which includes core 1, slider I2, slider II3, slider head 4, guide block 5, connecting Rod 6, main body 7 and driving guide device, slider I2 and slider II3 are slidably fitted on the front end of guide block 5, slider I2 and slider II3 are arranged in a ring at intervals at the front end of guide block 5, and the front end of slider I2 and slider II3 Form a complete circle; the rear end of the guide block 5 is connected with the front end of the connecting rod 6, the slider I2, the slider II3, the slider head 4, and the guide block 5 are located in the main body 7, and the rear end of the slider II3 is blocked by the pin 8 , the pin 8 is embedded in the front end of the main body 7; the front ends of the slider I2 and the slider II3 are offset against the rear end of the core 1, and the slider head 4 is set outside the front e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com