A Water Meter Error Correction Method Based on Fitting Equation

An error correction and equation fitting technology, applied in testing/calibration devices, measuring devices, instruments, etc., can solve the problems of exceeding the water meter error, the maximum allowable error range being in a critical state, and the cycle is long, so as to ensure the product qualification rate, The effect of shortening development time and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

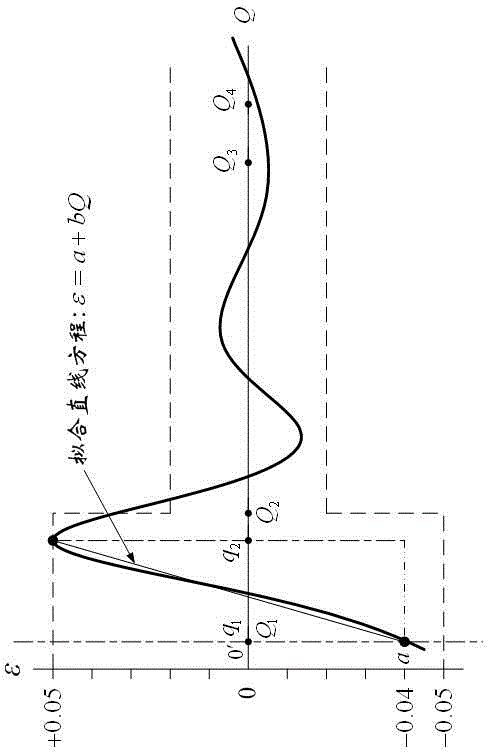

[0018] 1. First, detect several flow points within the flow measurement range of the water meter under the real flow state, and draw the error curve of the water meter on the graph, see figure 1 ;

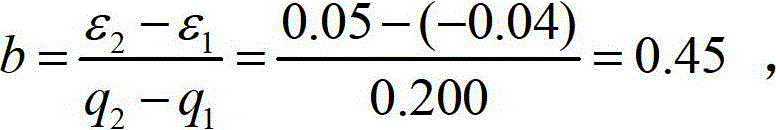

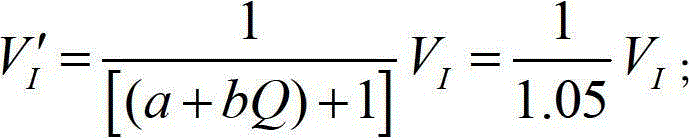

[0019] 2. Cut out a correction interval with good linearity from the error curve of the water meter, see figure 1 , now assume: q 2 =0.300m 3 / h,q 1 =0.100m 3 / h, draw a fitting straight line between the two interception points, and write the straight line equation: ε=a+bQ; translate the coordinate zero position from 0 to 0′, and the intercept of the straight line equation can be obtained: a=- 0.04, the slope of the line equation: b = ϵ 2 - ϵ 1 q 2 - q 1 = 0.05 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com