Testing device for extruding and lining of concrete

A test device and concrete technology, applied in the direction of applying stable tension/pressure to test the strength of materials, material inspection products, etc., can solve the problems of affecting the degree of surface settlement and high comprehensive cost, so as to reduce the cost of tunnel lining, save labor, Effect of suppressing land subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

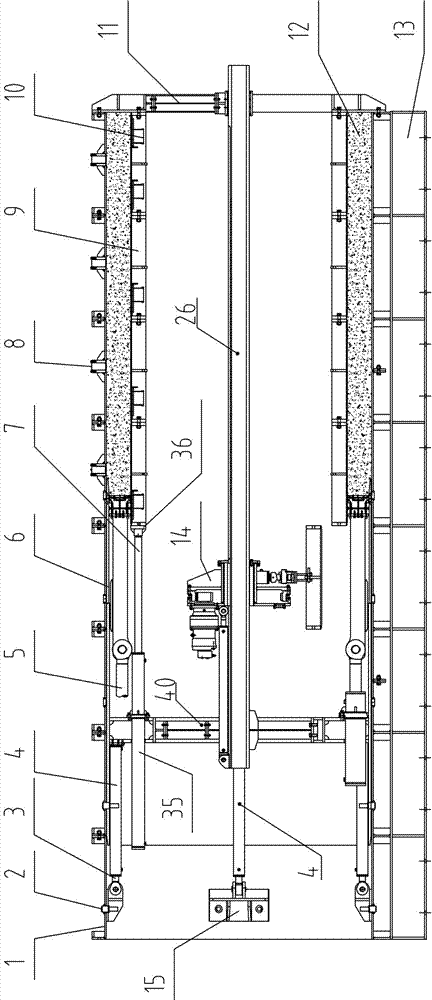

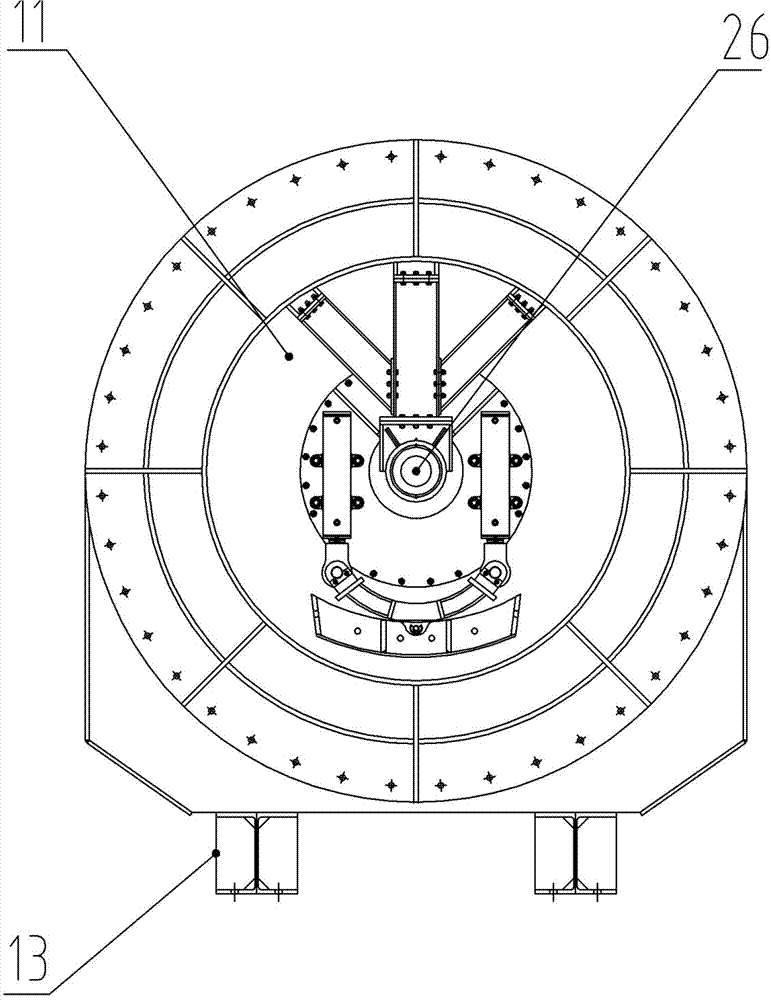

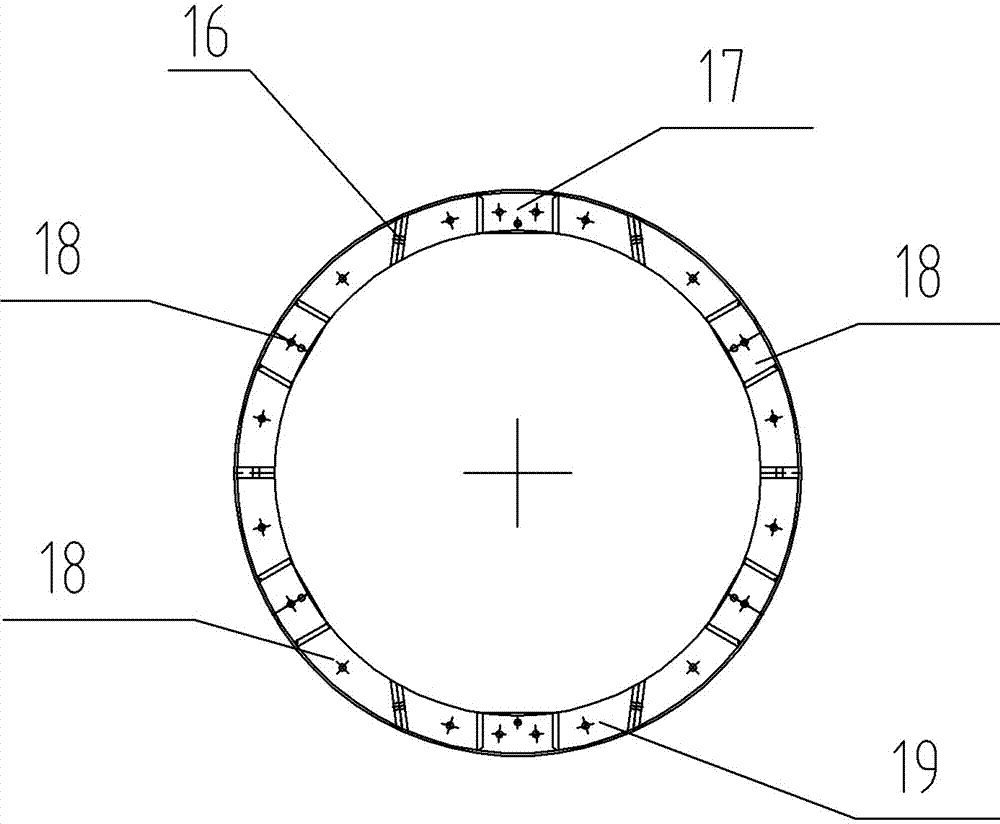

[0030] Embodiment 1: see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 , The concrete extrusion lining test device includes an outer layer cylindrical mold 1 and an inner layer cylindrical mold 9, both of which are mutually fitted and have a clearance fit. The rear ends of the outer layer cylindrical mold 1 and the inner layer cylindrical mold 9 are sealed by an end cap 11, and the center of the end cap 11 is provided with a hole for supporting and capable of sliding fit. Both the outer layer cylindrical mold 1 and the inner layer cylindrical mold 9 are formed by butt jointing of multiple ring-shaped unit bodies. Wherein, each segment unit body of the inner cylindrical mold 9 is a ring structure formed by splicing and fixing six arc-shaped templates, and the six arc-shaped templates are respectively an upper template 17, four side templates 18 and a lower template 19. And each unit body of the inner cylindrical mold 9 is provided with a concrete pouring port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com