Nozzle surface cleaning device and liquid droplet ejecting apparatus

A technology for cleaning device and nozzle surface, applied in printing and other directions, can solve the problems of image quality deterioration, difficult ink droplet, ink droplet ejection direction fluctuation, etc., to improve cleaning quality, effective and efficient nozzle surface cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, preferred embodiments of the present invention will be described based on the drawings.

[0043] [Overall Structure of Inkjet Recording Device]

[0044] First, the overall structure of the inkjet recording apparatus using the present invention will be described.

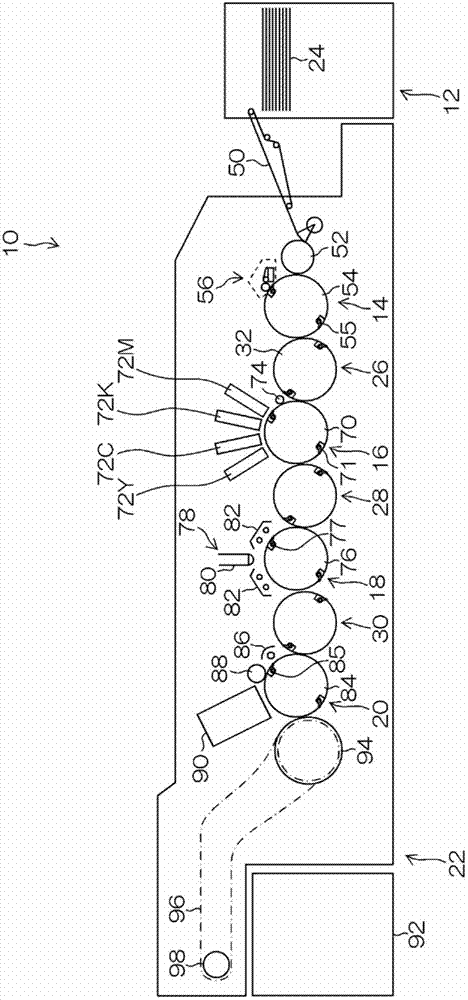

[0045] figure 1 It is a structural diagram showing the overall structure of an inkjet recording apparatus.

[0046] The inkjet recording apparatus 10 is a cylinder direct drawing type inkjet recording apparatus, which is on a recording medium 24 (for convenience, sometimes referred to as "paper") held on a cylinder (drawing drum 70) of the drawing section 16, From the inkjet heads 72M, 72K, 72C, 72Y, ink droplets of various colors are ejected to form the required color image. It is a drop-on-demand inkjet image forming device that uses two liquid reaction (agglutination) methods to eject ink droplets. Previously, a processing liquid (here, an agglutination processing liquid) was applied to the recording ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com