A track-type tension fixture

A rail-type, tension-resistant technology, applied in the direction of overhead lines/cable equipment, etc., can solve problems such as failure of repair tools and maintenance personnel, inconvenience in operation and maintenance work and daily management work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following will be described in conjunction with the accompanying drawings and specific embodiments.

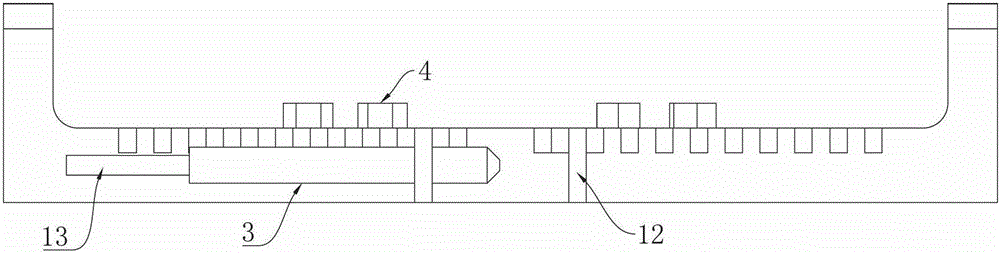

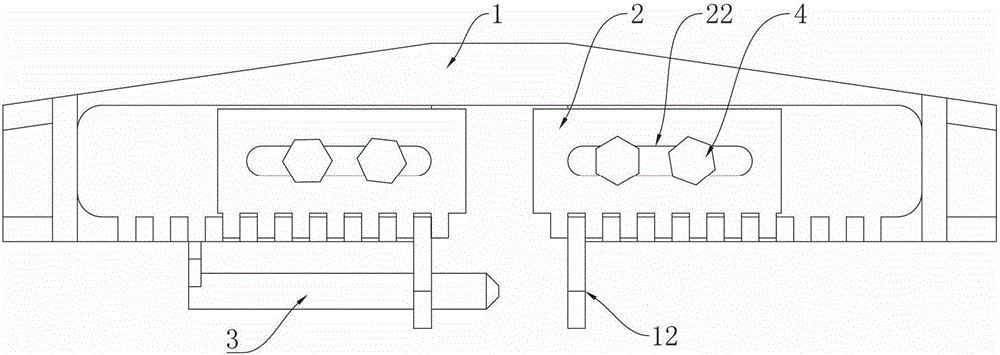

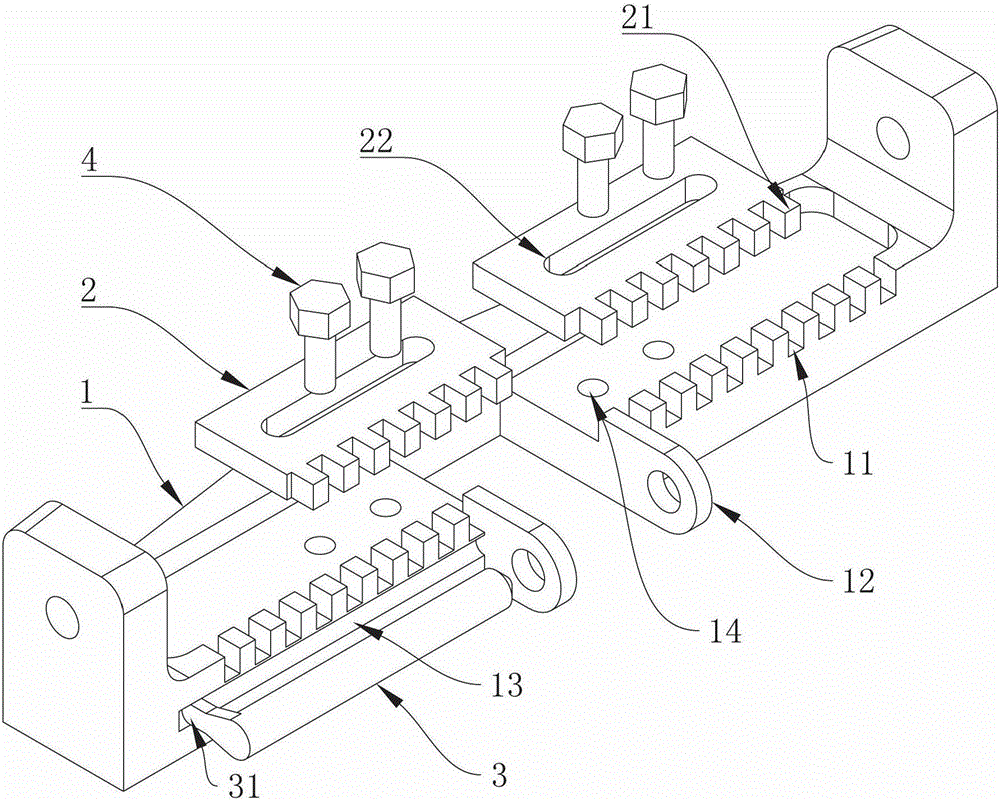

[0014] see Figure 1 to Figure 3 .

[0015] The track-type tension clamp described in this embodiment includes a base plate 1 , a track spring 2 , a locking bolt 3 and a track bolt 4 . Specifically, the structure of the rail-type tension clamp is that two rail clip springs 2 are fixed on the upper surface of the base plate 1 with track bolts 4 , and a lock bolt 3 is installed on the front end surface of the base plate 1 .

[0016] The structure of the substrate 1 is as follows: the left and right ends are provided with ear plates perpendicular to the upper end surface of the substrate, the ear plates are provided with connecting holes, the middle part of the substrate 1 is provided with a bayonet, and the left and right sides of the bayonet on the front surface of the substrate 1 are provided with locks The bolt fixing plate 12 is provided with locking bolt screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com