A vertical direct shear test device

A shear test, direct technology, applied in the test of the strength index of the shear surface of the sample under the condition of water seepage, the test and test part, the vertical direct shear test device field, can solve the particle difference shear surface shear surface The shear strength has a great influence on the problems, so as to achieve the effect of convenient production, convenient application and compact device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

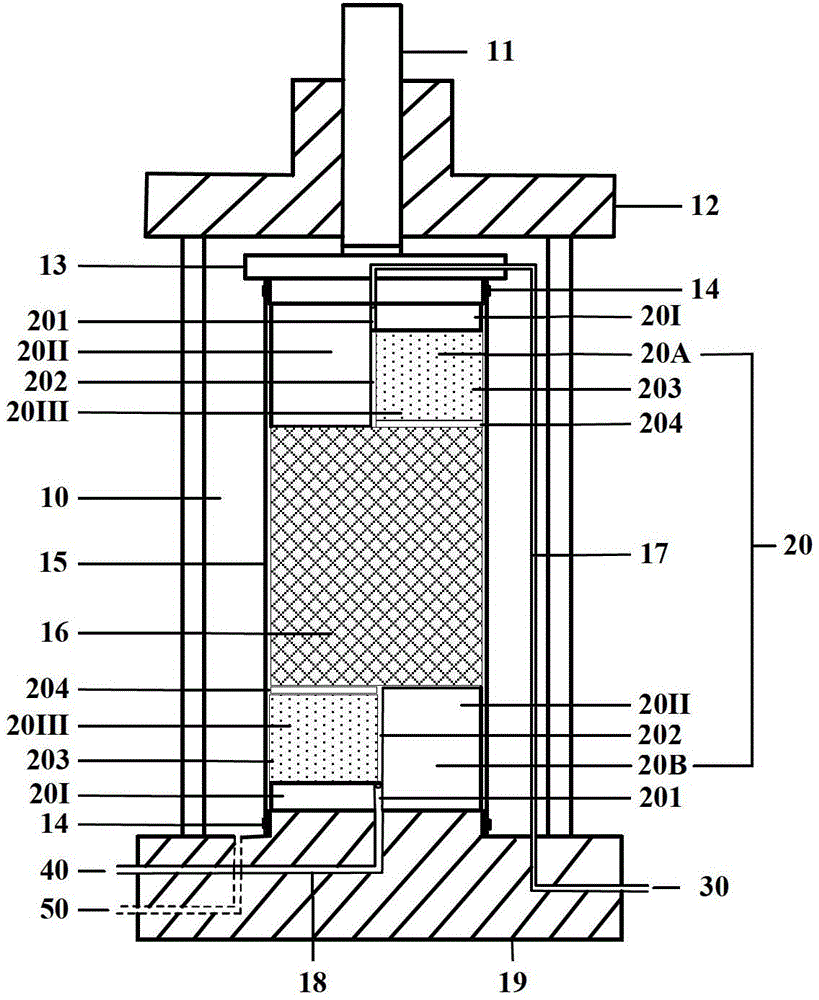

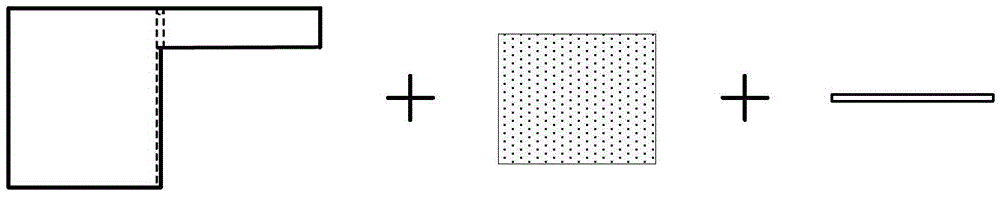

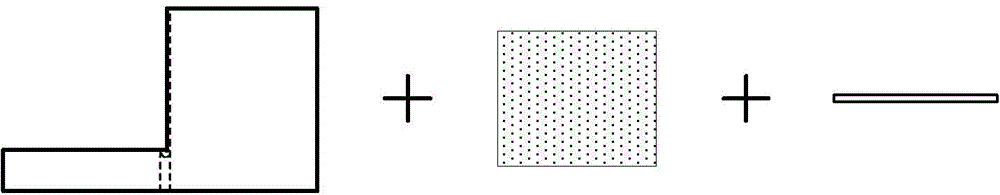

[0041] A vertical direct shear test device, comprising: base 19, water injection pipe 17 and drain pipe 18, pressure chamber 10 is provided on base 19, shear chamber upper cover 12 is provided on pressure chamber 10, pressure chamber 10 is provided with a rubber film cover 15, the lower end of the rubber film cover 15 is arranged on the base 19 and the lower end of the rubber film cover 15 is sealed with the base 19, and the upper shear box 20A and the lower shear box 20A are arranged in the rubber film cover 15. The box 20B, the upper shear box 20A and the lower shear box 20B are respectively located at the upper and lower ends of the rubber film cover 15, and the sample cavity 16 is surrounded by the rubber film cover 15, the upper shear box 20A and the lower shear box 20B, The upper shear box 20A and the lower shear box 20B adopt a shear assembly, and the shear assembly includes a base 20I, and a shear block 20II and a deformation block 20III are respectively arranged on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com