PTBD (Three-dimensional Combination Reinforcement) technology for treating after-built high and steep fill slope

A technology and slope technology, applied in the field of three-dimensional combined reinforcement technology, can solve the problems of low bonding strength between fill and anchor, low strength of fill itself, easy loss of prestress, etc., so as to avoid the problem of rolling edge effect, Solve the problem of local stability and ensure the effect of rolling quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

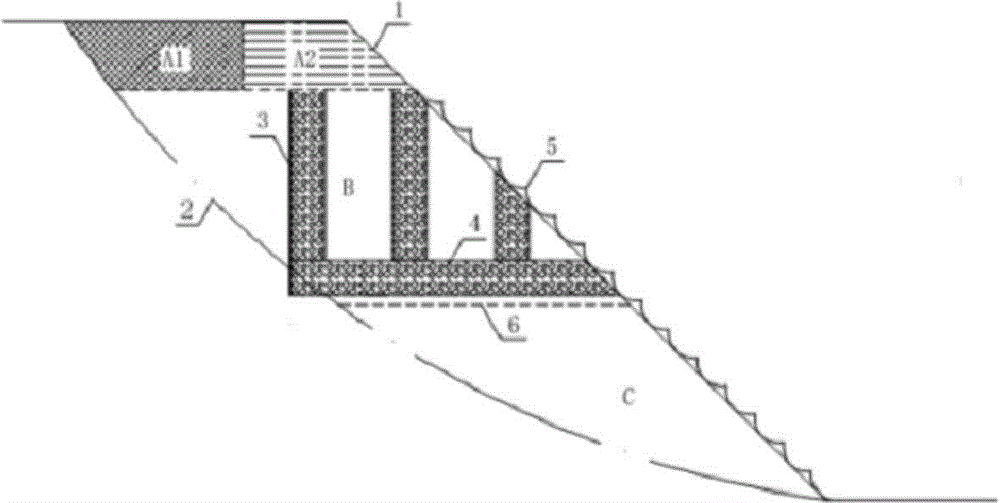

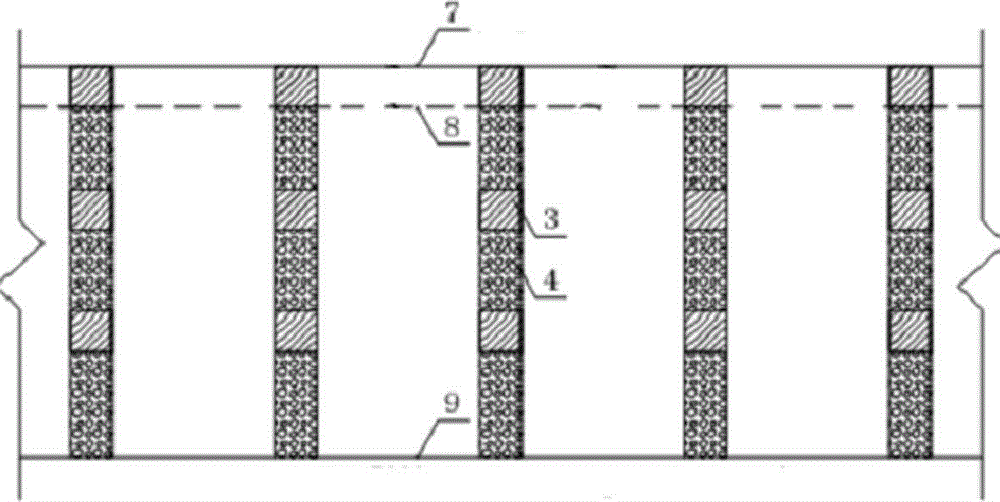

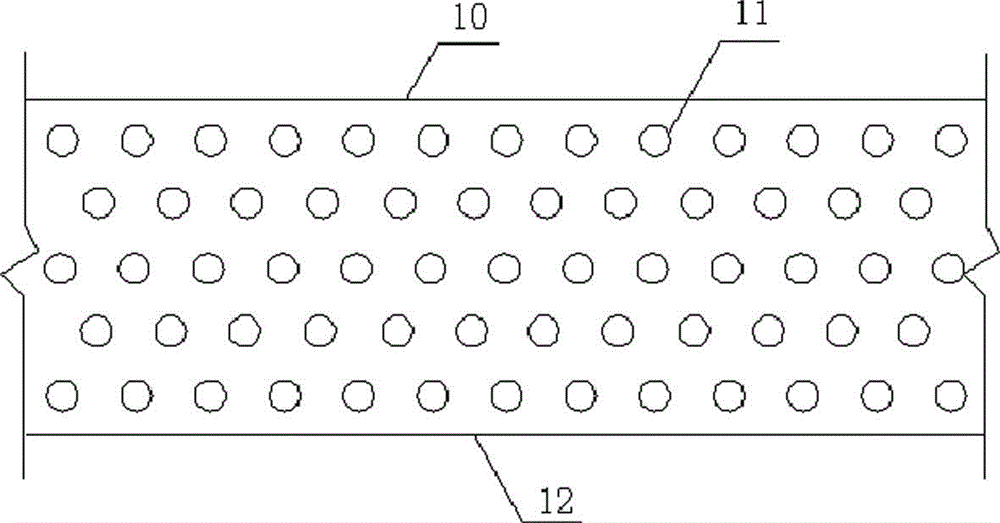

[0016] root tree figure 1 , figure 2 , image 3 , Figure 4 Shown: A PTBD technology for dealing with pre-built high and steep fill slopes, the specific implementation steps are as follows:

[0017] ①Tamping of the lower slope: The filling soil in area C outside the range of 1.2h times the critical infiltration depth of atmospheric rainfall below the top of the slope, that is, the filling soil in this area is layered by means of dynamic compaction combining point ramming and full ramming Compaction, and then use the H100 compaction machine to tamp the slope, the number of tamping is not less than 2, and the overlapping length of the tamping track is not less than 10cm.

[0018] ②Blind well with tree-shaped gabion in the central slope: Fill the soil within the range of 1.2h times the critical infiltration depth of atmospheric rainfall below the top of the slope, that is, area B, and first set up a gabion-built masonry well in the tree-like 2 of the central slope. The verti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap