Electronic expansion valve

A technology of electronic expansion valve and valve seat, which is applied in the direction of valve details, valve devices, valve energy absorption devices, etc., can solve the problems of high noise and achieve the effect of eliminating noise, eliminating the need for welding, and reducing installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Unless otherwise specified, the terms used in the context of the present invention have the meanings given below. Other terms not specifically given herein have their usual meanings in the art.

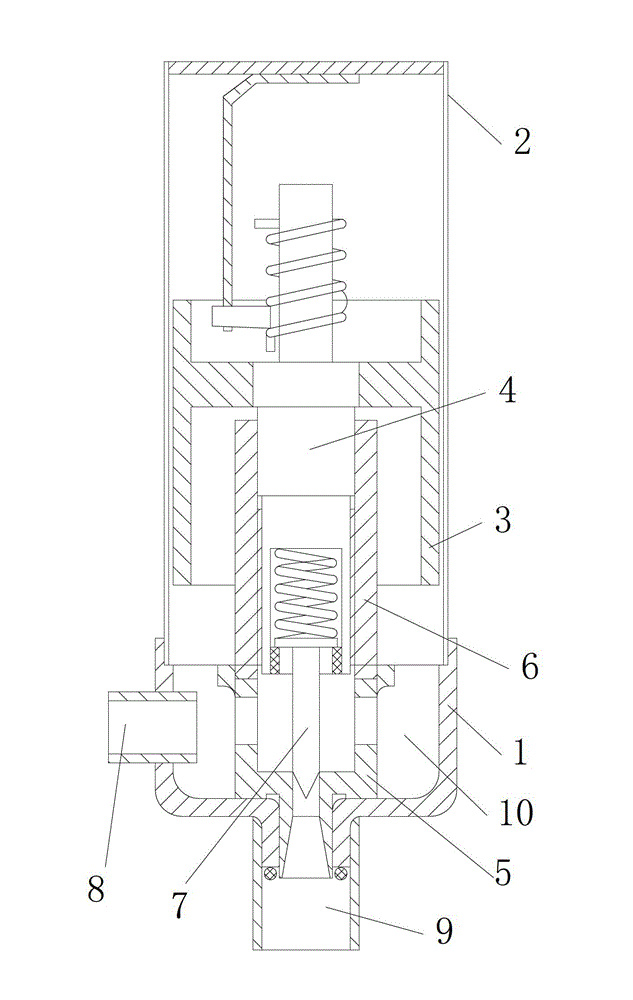

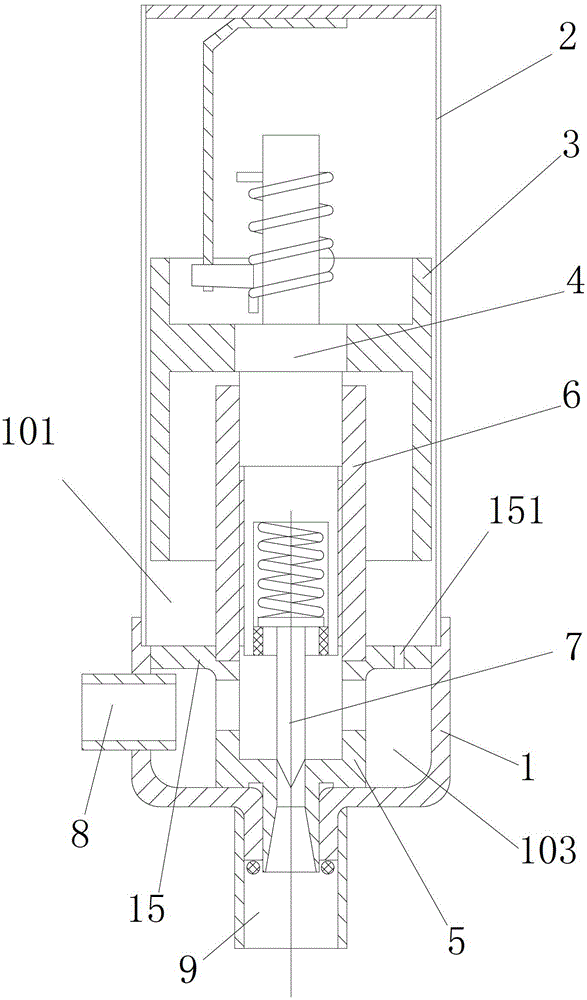

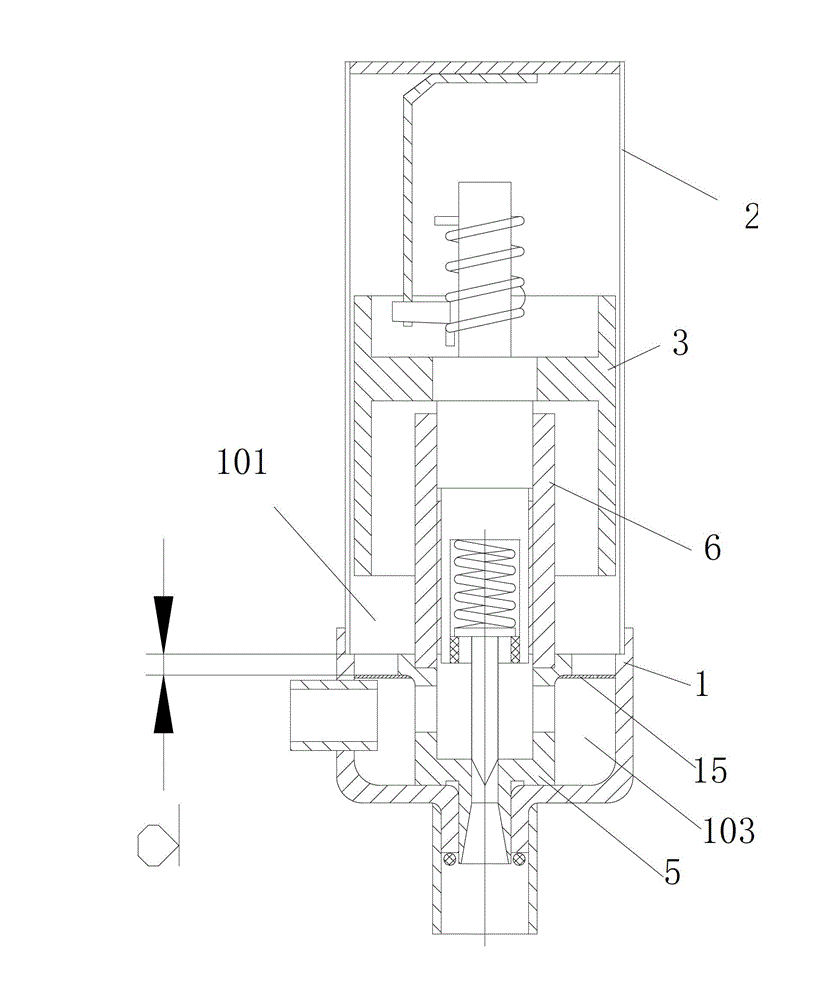

[0031] Such as Figure 2 to Figure 8 As shown in the drawings, the electronic expansion valve according to the embodiment of the present invention includes: a valve body 1, a sleeve 2 connected to the upper end of the valve body 1, a valve seat 5 arranged in the valve body, and a nut 6 connected to the upper end of the valve seat 1. The magnetic rotor 3 arranged outside the nut and cooperating with the upper part of the nut through the screw rod 4 . A cavity is formed between the inner wall of the sleeve and the valve body and the nut and the outer wall of the valve seat. The electronic expansion valve can also include: an inlet pipe 8 and an outlet pipe 9 arranged on the valve body. The above-mentioned structure can adopt the structure of the existing electronic expansion va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com