Attitude leveling control method for vertical launch platform based on twelve-point supports

A technology of vertical launch and launch platform, applied in the direction of control using feedback, it can solve the problems of strong electromagnetic interference, complex control, and excessive static indetermination, and achieve the effect of weakening strong coupling, ensuring high precision requirements and smooth implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0056] combine Figure 1 to Figure 3 as well as Figure 24 and Figure 25 , a method for controlling attitude leveling of a vertical launch platform based on twelve points of support, comprising the following steps:

[0057] Step 1, establish the mathematical model of the attitude leveling system of the vertical launch platform supported by twelve points, as follows:

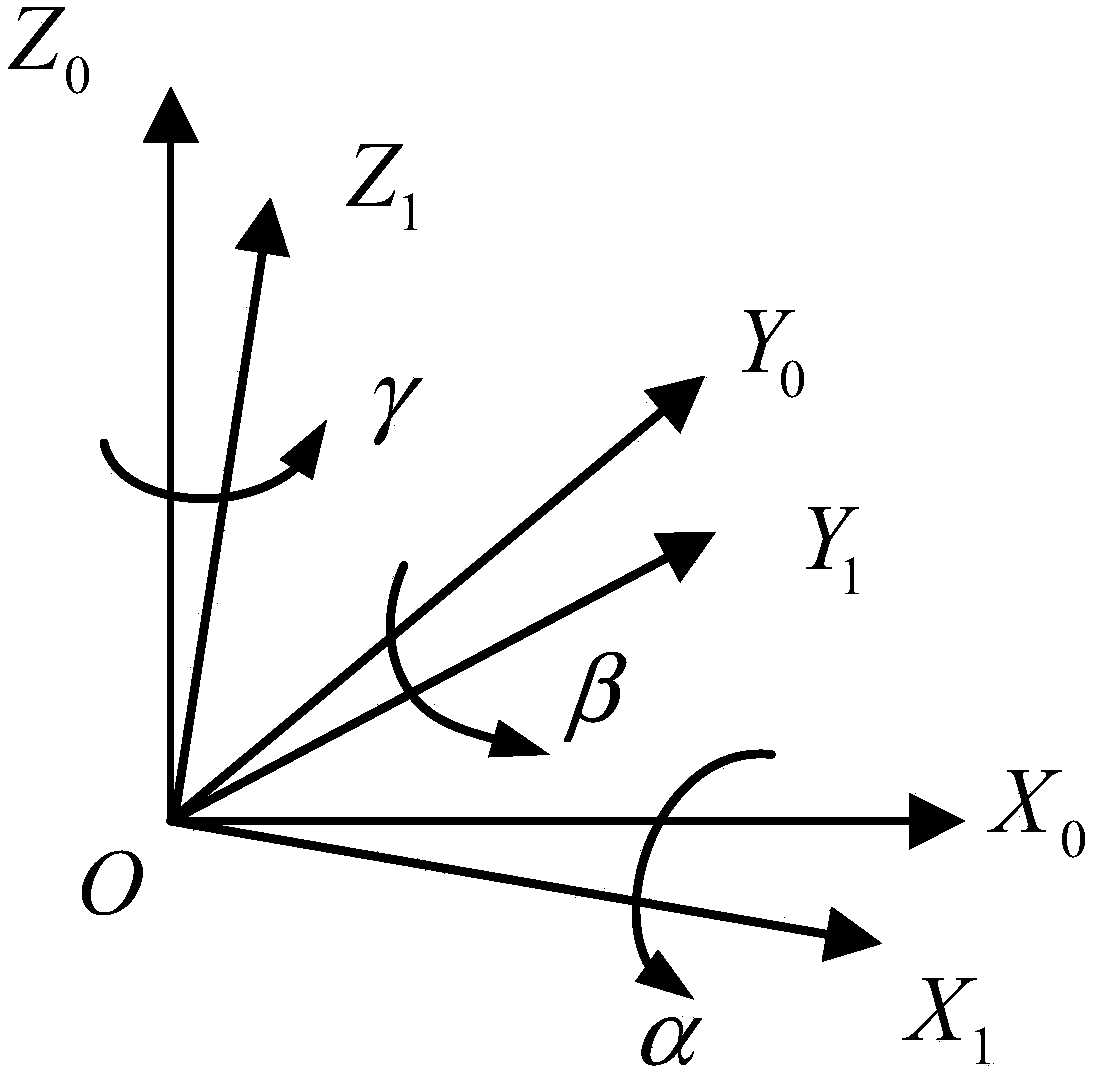

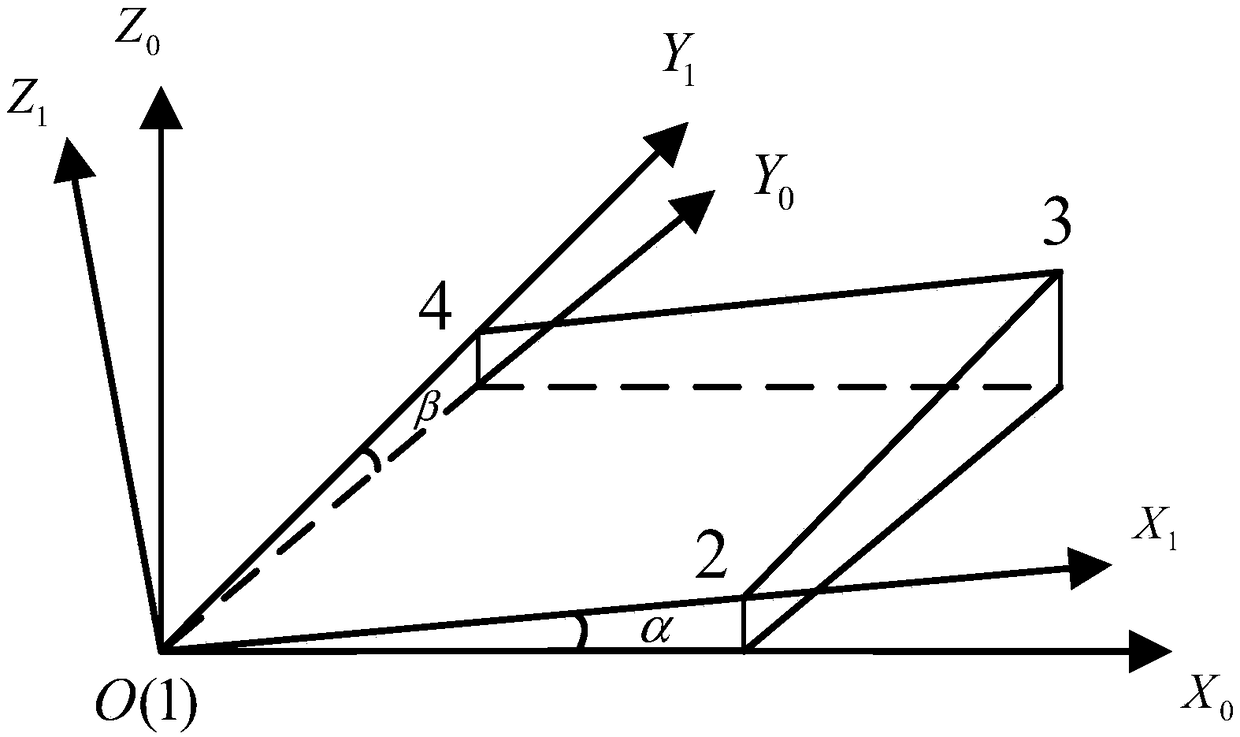

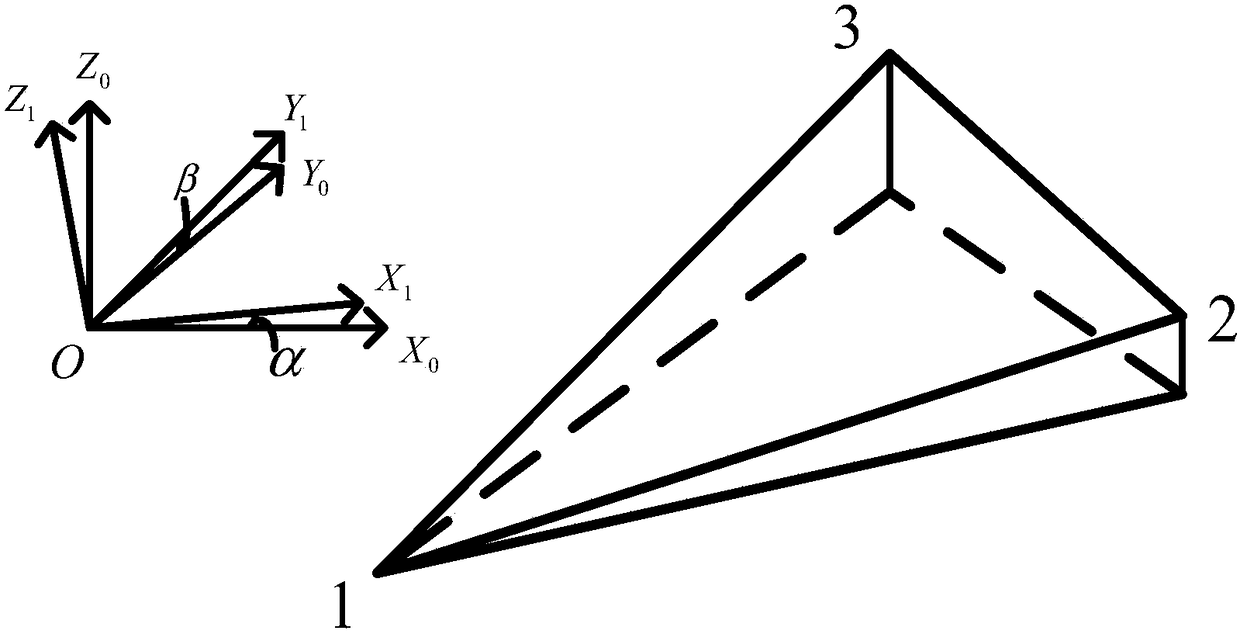

[0058] Set OX 0 Y 0 Z 0 is the horizontal coordinate system, keep still, OX 1 Y 1 Z 1 is a non-horizontal coordinate system, by the horizontal coordinate system OX 0 Y 0 Z 0 After a series of rotations, the schematic diagram of the rotation change is as follows figure 1 shown. It is stipulated here that the rotation angle direction satisfies the right-hand spiral rule, that is, the thumb points to the positive direction of the rotation axis, and the bending direction of the four fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com