Hinge for furniture

A technology for hinges and furniture, applied in the field of hinges, can solve the problems of strong contact pressure, wear of torsion springs and parts, affecting the life of torsion spring hinges, etc., to reduce pressure, reduce rigid friction, and open and close smoothly and reliably.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

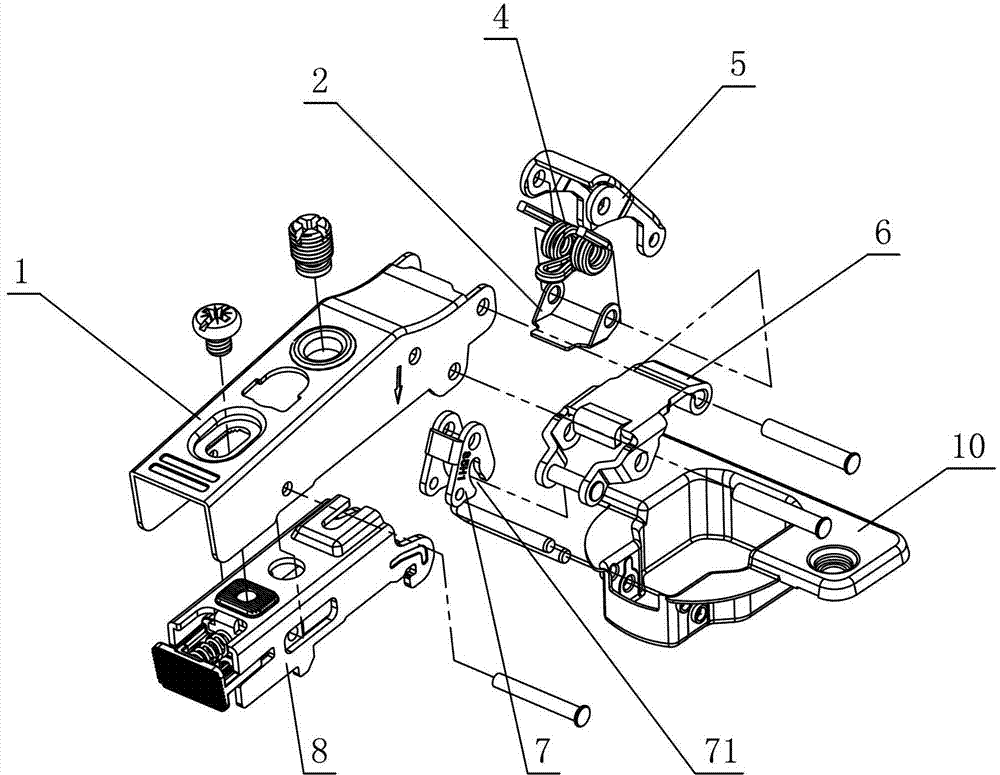

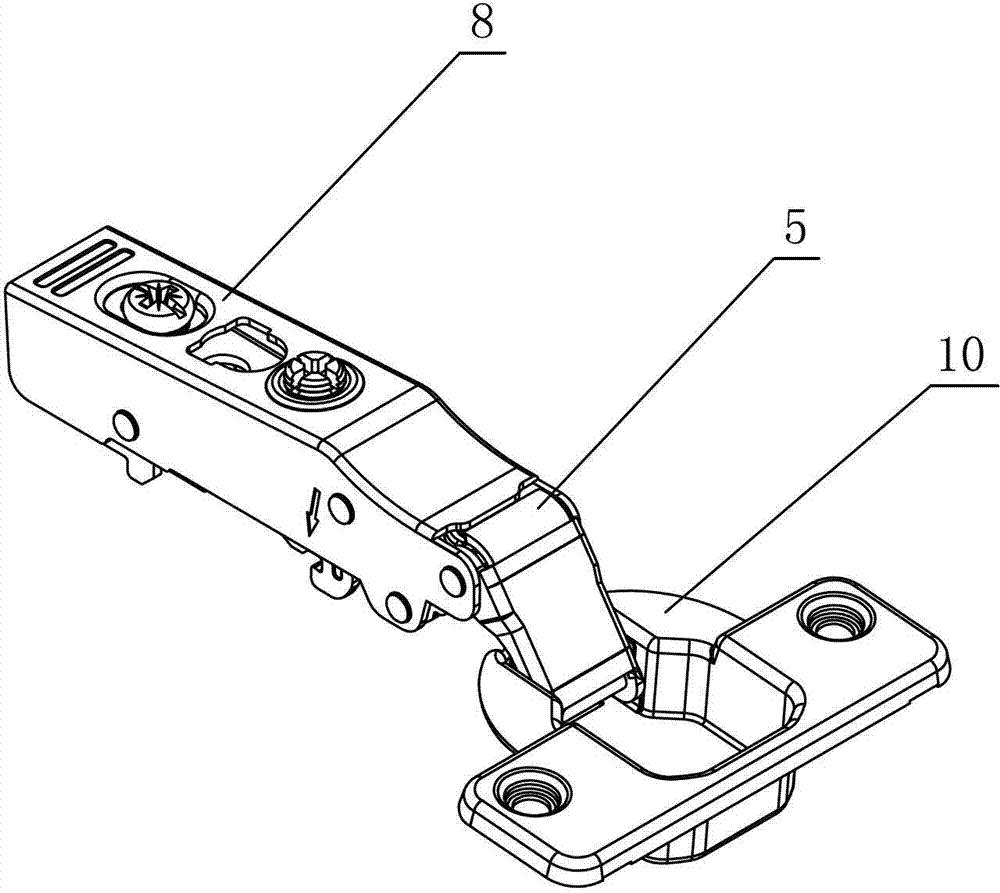

[0026] see figure 1 - Figure 5 , the hinge for this furniture, including the connecting arm 1 and the movable cup holder 10 connected by the swing arm, the hinge is provided with a torsion spring 4 that at least generates an opening and closing force on the movable cup holder 10, and the connection between the torsion spring 4 and the inner swing arm 6 There is a wear-reducing block A 2 between them, and the wear-reducing block A 2 is slidably connected with the inner swing arm 6 during the opening and closing of the hinge; the wear-reducing block A 2 is provided with a fixed part, and a pin shaft is interspersed on the fixed part and fixed on the outer swing on arm 5.

[0027] The components of this hinge are combined as follows: the swing arm includes an outer swing arm 5 and an inner swing arm 6; the torsion spring 4 is positioned at the hinge of the connecting arm 1 and the outer swing arm 5 through a pin; the torsion spring 4 includes a head support foot 41 , the middl...

no. 2 example

[0030] see Figure 6 - Figure 8 , the hinge for this furniture, the wear-reducing block 3B is a plastic part, in the shape of a groove, and is provided with longitudinal side parts 31 on both sides, and a transverse through hole 32 is provided on the longitudinal side part 31; the wear-reducing block B 3 is placed on the torsion spring 4, the slot 33 is fitted into one end of the inner swing arm 6, and a pin shaft is inserted through the transverse through hole 32 to be fixedly arranged at the hinge of the inner swing arm 6 and the connecting arm 1. Other unmentioned parts are the same as the first embodiment.

no. 3 example

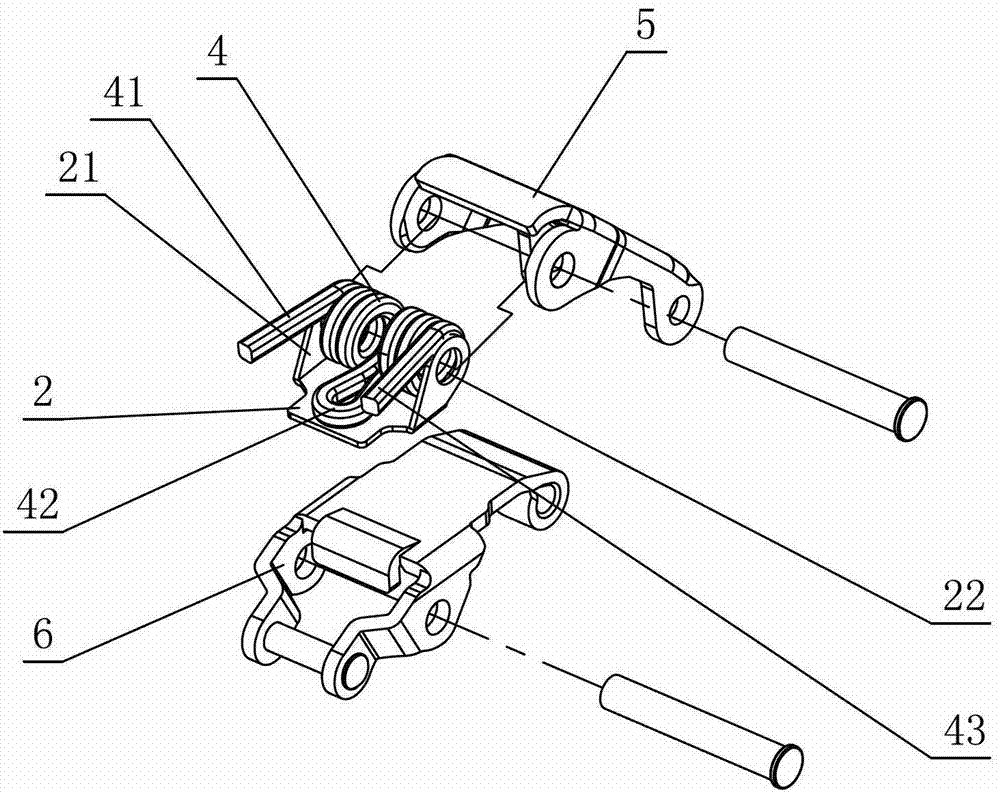

[0032] see Figure 9 - Figure 11 , the hinge used for this furniture, the wear-reducing block includes wear-reducing block A 2 and wear-reducing block B 3; the wear-reducing block A 2 is a plastic part or a metal part, in the shape of a plate or a block, and is provided with longitudinal side parts on both sides 21. The longitudinal side 21 is provided with a transverse through hole 22; the anti-friction block A2 is placed under the torsion spring 4, and the pin shaft is interspersed in the transverse through hole 22 and fixed at the hinge of the outer swing arm 5 and the connecting arm 1; Abrasive block B 3 is a metal piece or a plastic piece, which is in the shape of a groove, and is provided with longitudinal side portions 31 on both sides, and a transverse through hole 32 is provided on the longitudinal side portion 31; the wear-reducing block B 3 is placed on the wear-reducing block A 2 Below, the slot 33 is fitted into one end of the inner swing arm 6 , and a pin shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com