A hinge opening and closing force adjustment mechanism

A technology for adjusting mechanisms and hinges, which is applied to hinges with pins, building structures, and switches with braking devices, etc. It can solve the problems of not having a good buffer effect, failing to meet the use requirements, and affecting the life of the buffer. , to achieve the effects of small collision, uniform force and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

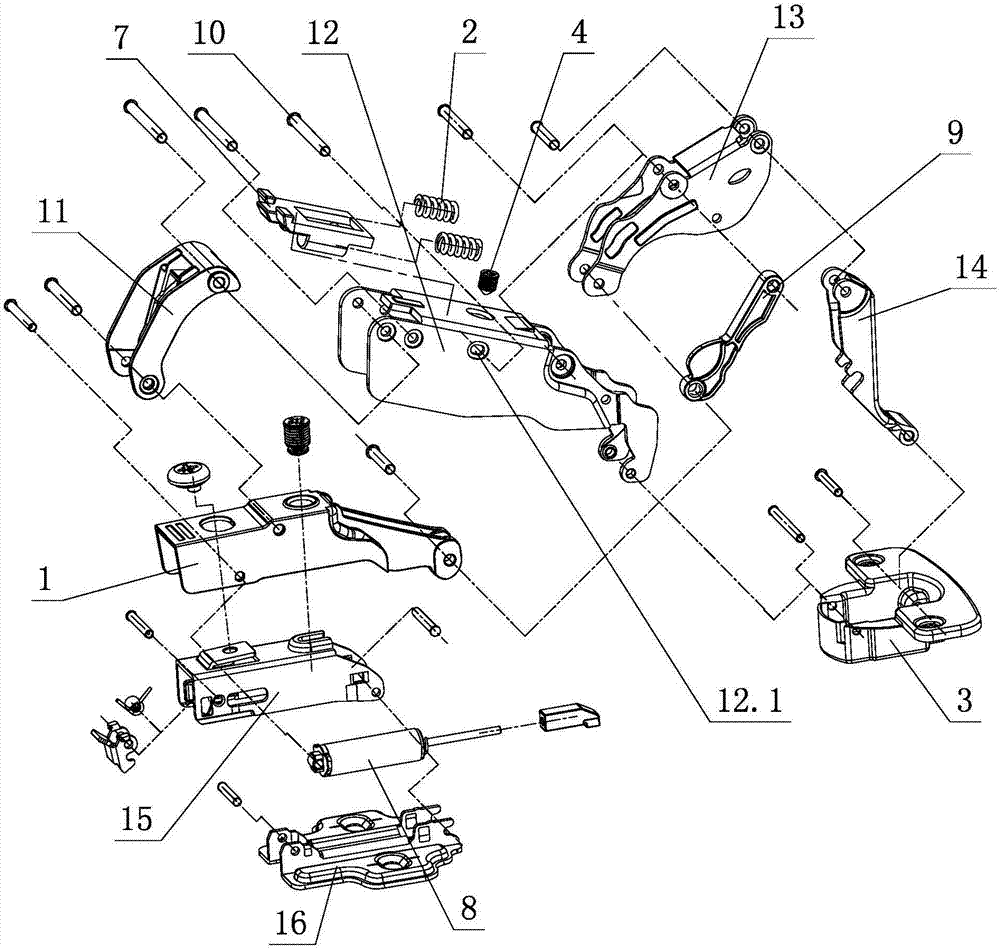

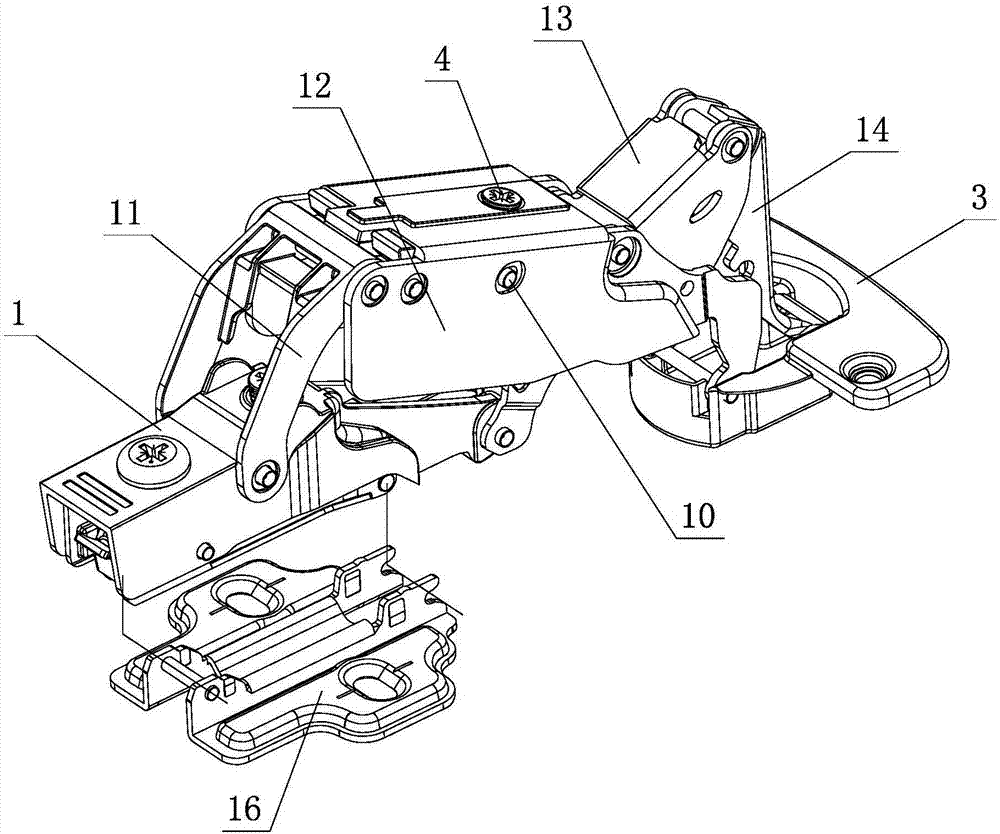

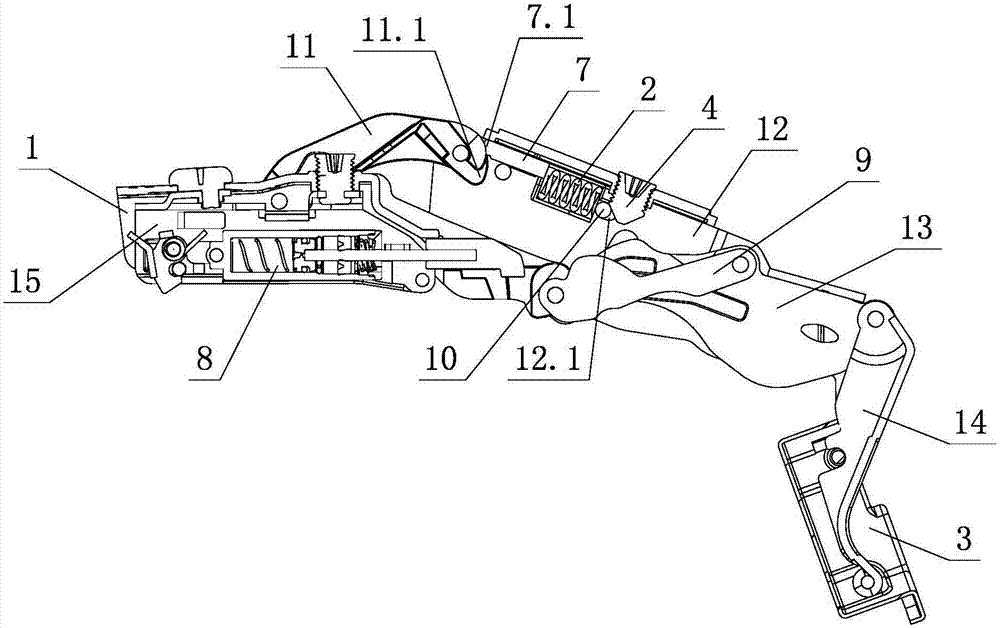

[0022] see Figure 1-Figure 8 , the hinge opening and closing force adjustment mechanism includes connecting arm 1, hinge cup seat 3, transmission arm assembly, damper 8 and elastic device, the two ends of the transmission arm assembly are respectively connected to the connection arm 1 and hinge cup seat 3 in rotation, and the connection arm 1 Through the cooperation of the transmission arm assembly and the elastic device, the hinge cup seat 3 is hinged to realize the hinged opening and closing of the hinge, wherein at least when the hinge is closed, the damper 8 is used to realize the damping buffer closing, and the transmission arm assembly includes at least the first The transmission arm 11 and the second transmission arm 12, the elastic device is arranged on the first transmission arm 11 or the second transmission arm 12, and includes the elastic el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com