Pier stud prefabricating pouring system and remote pouring method thereof

A pier column and side formwork technology is applied in the field of prefabricated pouring systems for pier columns, which can solve the problems of low production efficiency of pier column pouring, high labor intensity, complicated construction conditions, etc., and achieves smooth and reliable opening and closing action and high pouring efficiency. , The effect of high pouring precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

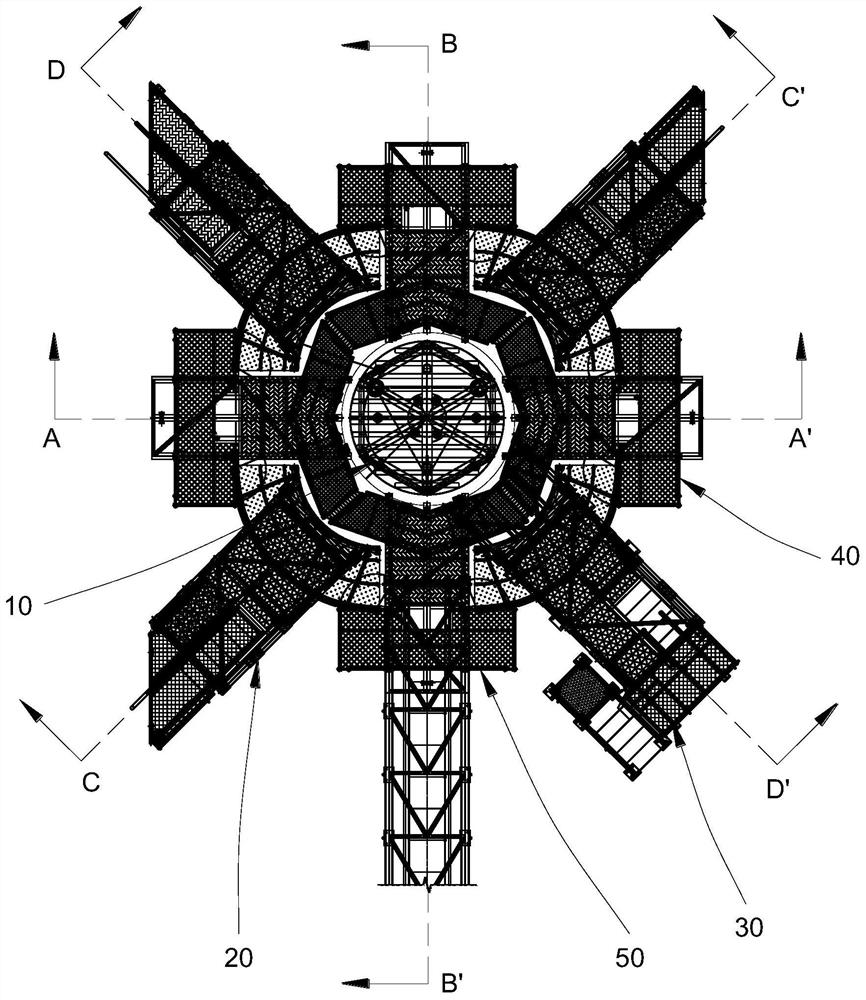

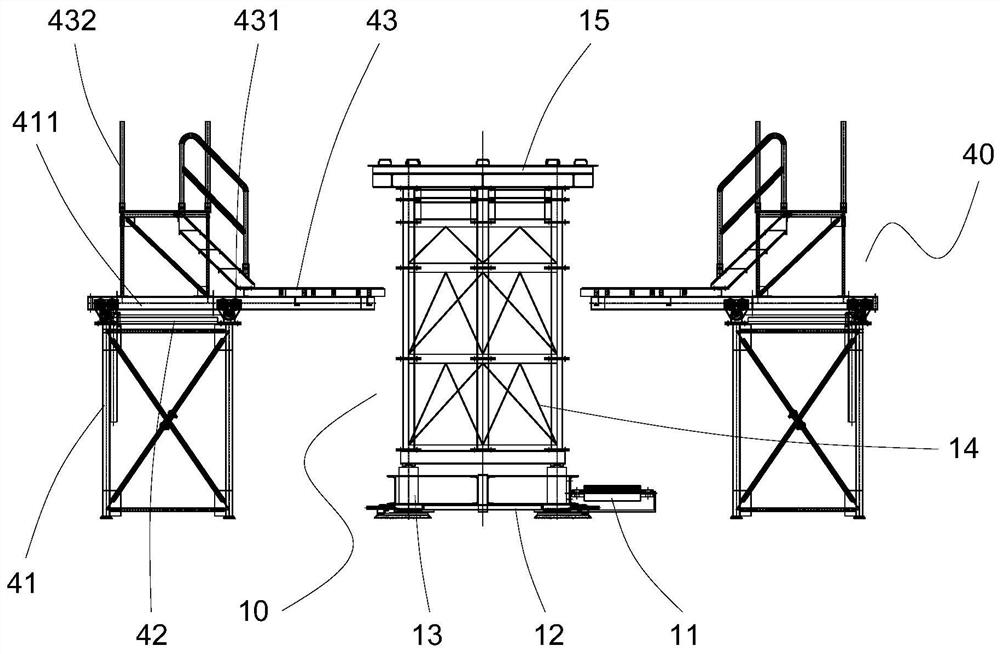

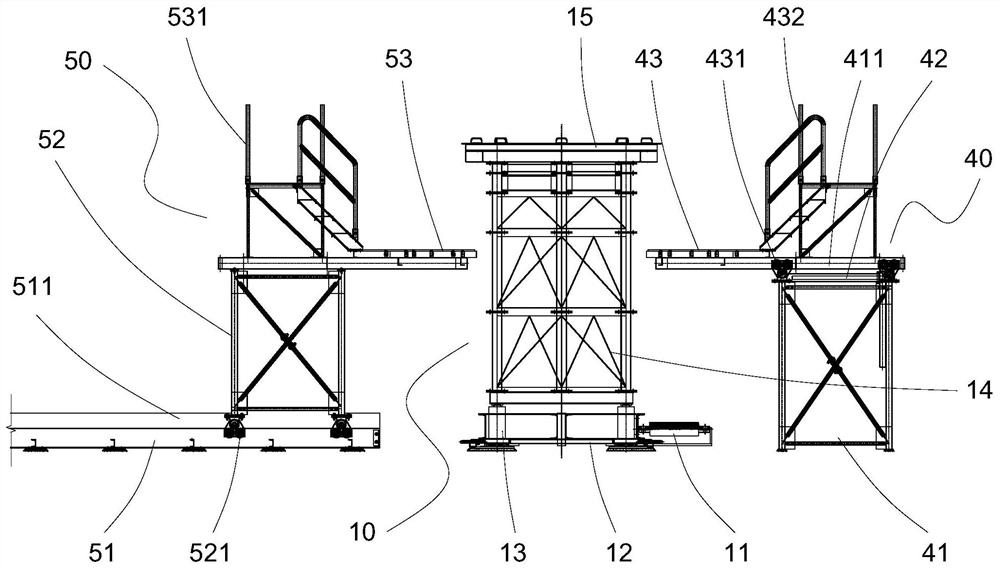

[0028] refer to Figure 1 to Figure 5 .

[0029] The embodiment of the present invention discloses a prefabricated pouring system for pier columns, which includes a bottom mold assembly 10, and four side mold assemblies and four cleaning assemblies are arranged alternately around the bottom mold assembly 10, that is, two adjacent A cleaning assembly is arranged between the side mold assemblies, and a side mold assembly is arranged between two adjacent cleaning assemblies. The alternate arrangement can make full use of the space around the bottom mold assembly 10, avoiding side mold assemblies and cleaning assemblies. Mutual obstruction during movement, stable and reliable mold opening and closing acti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com