Refrigerator defrosting control method

A control method and technology for refrigerators, applied in defrosting, household refrigeration devices, lighting and heating equipment, etc., can solve the problems of untimely defrosting, poor refrigeration effect of refrigerators, unnecessary defrosting, etc., and reduce defrosting and defrosting. The effect of frost delay and simplified defrost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

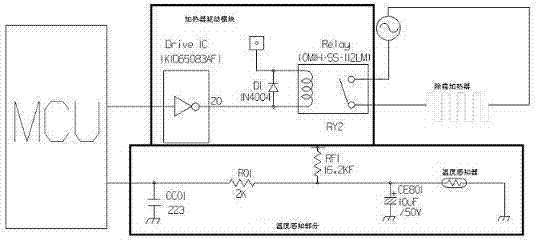

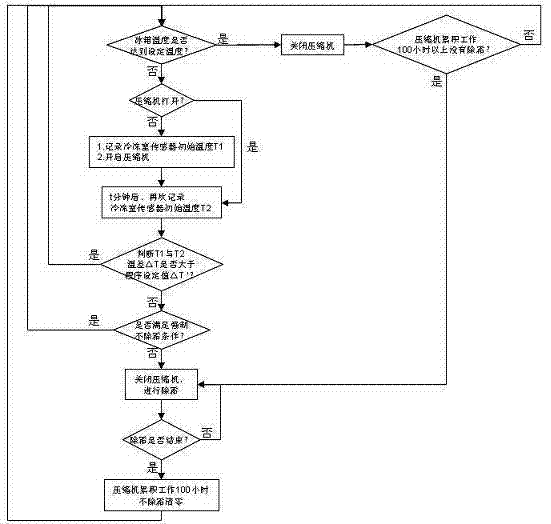

[0031] Such as figure 1 As shown, the defrosting circuit board is divided into a heater drive module, a temperature sensing part mainly including a temperature sensor, a data acquisition and processing part that is a microcontroller MCU, and a defrosting heater. Compared with the traditional technology, the temperature sensing part is increased. part, so that the frosting of the evaporator can be judged according to the temperature change in the freezer chamber of the refrigerator, and then whether defrosting is required. The specific steps are:

[0032] Step A. The initial temperature in the freezing chamber is collected by the temperature sensor, and the temperature data is converted into an electrical signal and transmitted to the microcontroller;

[0033] Step B. The microcontroller records the initial temperature T1;

[0034] Step C. Make sure the compressor is working; if the compressor is not working at this time, you need to turn on the compressor first, if the compre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com