Water jacket on casting roller of twin roller caster

A twin-roll casting mill and casting roll technology, which is applied in the field of twin-roll casting mills, can solve the problems of size change, large size, repeated cycles, and impact on the quality of strip steel, and achieve the effects of reducing deformation, reducing cost, and improving heat dissipation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

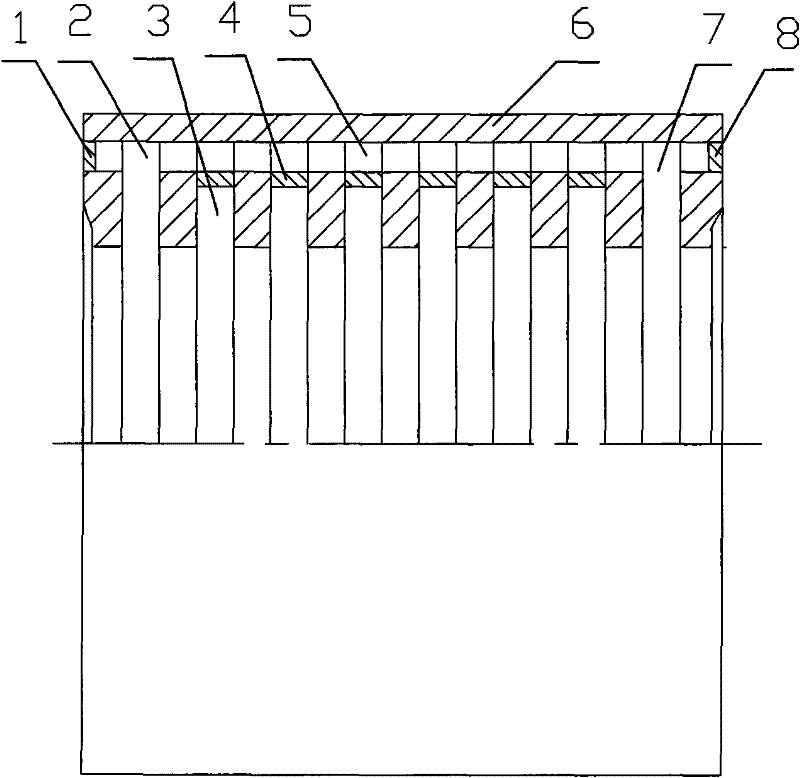

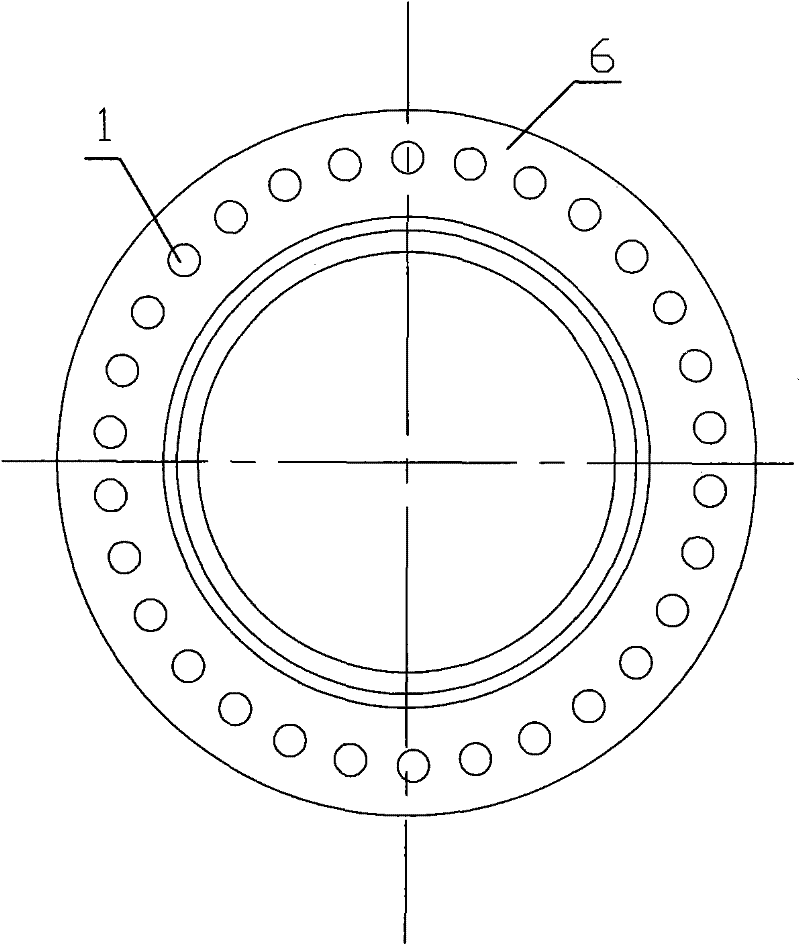

[0015] Embodiment one, as attached figure 1 , 2 Shown: a casting roll water jacket with only one cooling water circuit, it includes a water jacket body 6 installed on the casting roll, the water jacket body 6 is a cylinder, and the water jacket body 6 A circle of radiating holes 5 is evenly distributed along the axial direction at both ends, the radiating holes 5 are through holes, and the two ends of the radiating holes 5 are closed with plugs 1,8. A row of annular grooves 3 are arranged on the inner wall of the water jacket body 6, and the annular grooves 3 are evenly distributed on the inner wall of the water jacket body 6. The thickness from the bottom of the annular grooves 3 to the surface of the water jacket body 6 is the same as the outer circle of the cooling hole 5 to the water jacket body 6 The thickness of the surface is the same. An annular spacer ring 4 is also provided in the annular groove 3, and the distance between the outer surface of the annular spacer ri...

Embodiment 2

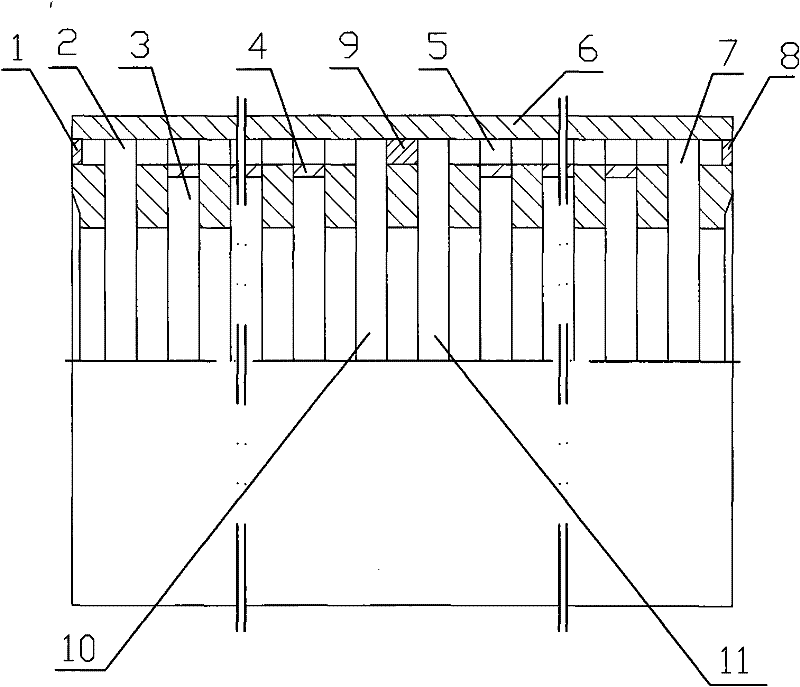

[0016] Embodiment two, a kind of casting roll water jacket of a twin-roll casting mill with two cooling water circuits, as attached figure 2 , 3 As shown: it includes a water jacket body 6 installed on the casting roll. It is a through hole, and the two ends of the cooling hole 5 are closed with plugs 1,8. A row of annular grooves 3 are arranged on the inner wall of the water jacket body 6, and the annular grooves 3 are evenly distributed on the inner wall of the water jacket body 6. The thickness from the bottom of the annular grooves 3 to the surface of the water jacket body 6 is the same as the outer circle of the cooling hole 5 to the water jacket body 6 The thickness of the surface is the same. An annular spacer ring 4 is also provided in the annular groove 3, and the distance between the outer surface of the annular spacer ring 4 and the bottom of the annular groove 3 is the same as the diameter of the heat dissipation hole 5. In order to facilitate installation, the ...

Embodiment 3

[0017] Embodiment three, a kind of casting roll water jacket of two-roll casting rolling mill that has three cooling water loops, as attached figure 2 , 4 As shown: it includes a water jacket body 6 installed on the casting roll. It is a through hole, and the two ends of the cooling hole 5 are closed with plugs 1,8. A row of annular grooves 3 are arranged on the inner wall of the water jacket body 6, and the annular grooves 3 are evenly distributed on the inner wall of the water jacket body 6. The thickness from the bottom of the annular grooves 3 to the surface of the water jacket body 6 is the same as the outer circle of the cooling hole 5 to the water jacket body 6 The thickness of the surface is the same. An annular spacer ring 4 is also provided in the annular groove 3, and the distance between the outer surface of the annular spacer ring 4 and the bottom of the annular groove 3 is the same as the diameter of the heat dissipation hole 5. In order to facilitate installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com