A connector that prevents screw back

A connector and thread technology, which is applied in the field of anti-thread regression connectors, can solve problems such as complex structures, and achieve the effects of solving multiple complex structures of parts, reducing the number of parts, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

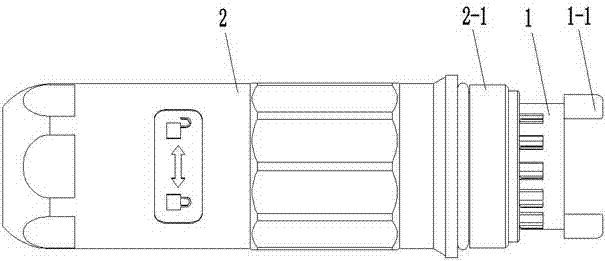

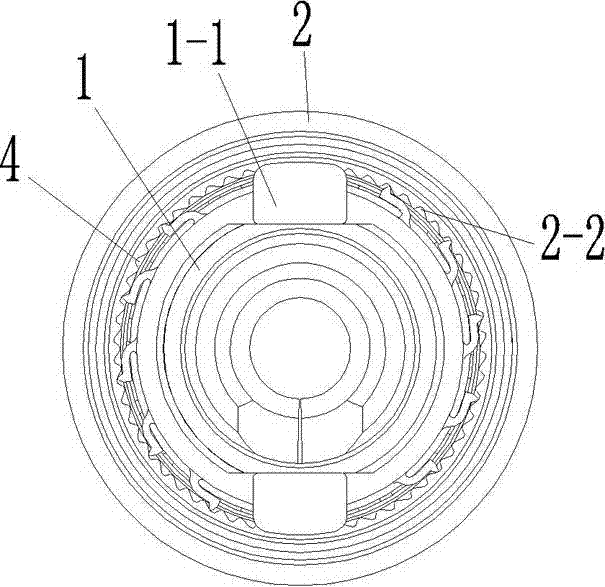

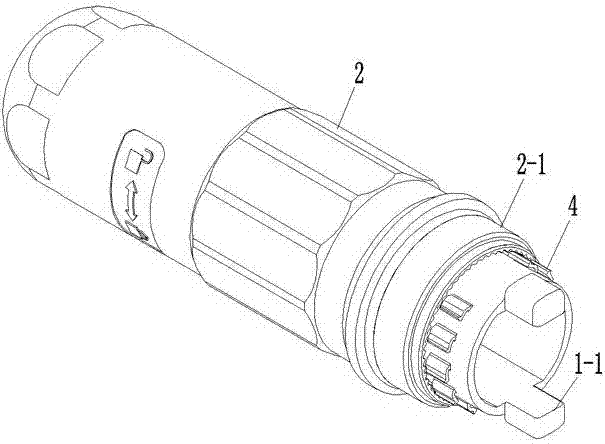

[0019] Embodiment 1 of the anti-thread backward connector of the present invention, such as Figure 1-9 As shown, it includes an inner casing 1 and an outer casing 2. The outer casing 2 is coaxially sleeved outside the inner casing 1 and rotates with the inner casing 1. In addition, the front end of the outer casing 2 is provided for matching with the The external thread 2-1 of the connector 3 is threaded, and the inner housing 1 is provided with an anti-rotation structure for anti-rotation cooperation with the adapter 3. In this embodiment, the anti-rotation structure is provided at the front end of the inner housing 1 , specifically two guide columns 1-1 arranged on the front end surface of the inner casing 1, the two guide columns 1-1 are evenly distributed on the front end surface of the inner casing 1 around the centerline of the inner casing 1, and, The thickness of each guide column in the radial direction of the inner housing is greater than the thickness of the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com